How can downtime be reduced by using an adapter?

Beke Nieszytka | 21. July 2020

Have you ever heard of automatic parking systems?

Automatic parking systems use conveyor technology to bring vehicles into parking position vertically and/or horizontally. There are two types of automatic parking systems:

- Semi-automatic systems

- Fully automatic systems

Whereas in semi-automatic systems the user is inside the system and must constantly control the parking process at the push of a button, fully automatic systems do not provide access to the inside of the parking system. The functional principle and control logic of automated high-bay storage systems are replicated here. In fully automated systems, the user drives his car in an entrance area onto a movable platform, which is later moved by the system. He receives a parking ticket for the delivery of the vehicle and the automatic parking process begins. The system weighs and measures the car and then automatically moves it to a suitable parking position using shifting units or lifting cranes.

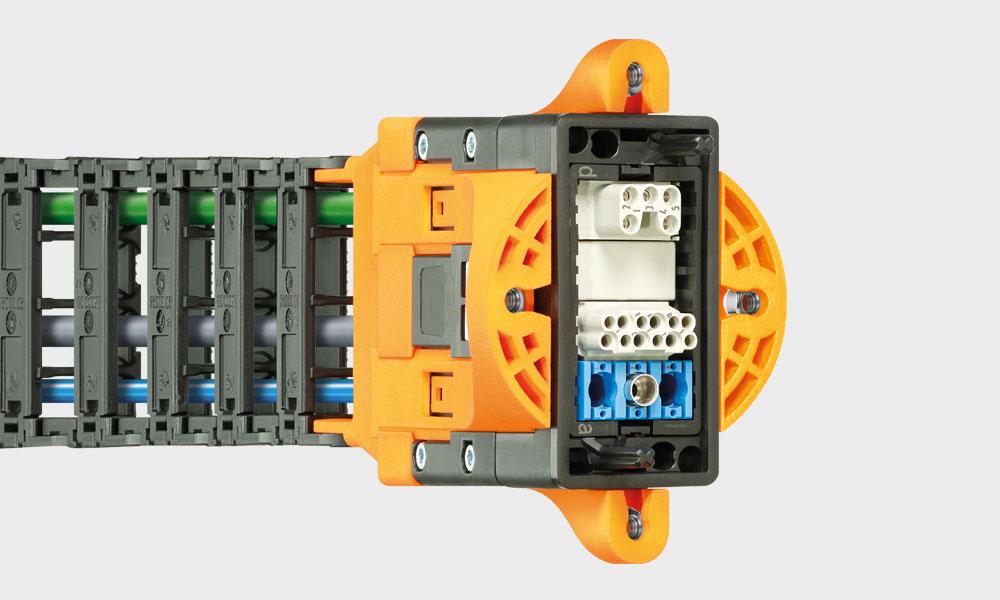

In order to supply the parking system continuously with energy, energy supply lines are installed inside the system. These consist of energy chains in which the appropriate cables including connectors are guided. If there is a cable rupture within the energy chain, for example, this quickly leads to a standstill of the system.

Just imagine …

… You are a service employee in such a fully automated parking system and there is actually a system downtime. The next step is up to you! You need to get the system running again as soon as possible.

How do you tackle the problem? You will probably first determine exactly where the problem lies in the system. You discover that there has been a cable rupture within an energy chain and the affected cable must be replaced.

The next thing you can do is to dismantle the energy supply system, open it up, locate the defective cable in it and replace it with a new cable of exactly the same design. After inserting the new intact cable, the energy supply system must be closed, installed in the correct position and reconnected.

This takes time and money! Replacing the entire energy supply system involves many individual steps that cannot be completed in a short time.

Isn’t this faster and easier? Ready to install instead of many individual steps

Wherever energy supply systems need to be connected quickly and easily, the Module Connect adapter is the solution. When servicing is required, for example, it ensures that the energy supply line is quickly connected to the system. In particular, long machine downtime can be avoided.

The adapter is designed to connect the Module Connect interface concept and the energy chain to a coherent system. It is a further step towards the plug and play e-chain. Depending on the chain series, chain width and number of modules, the Module Connect is connected to the energy chain by an individually designed component.

This can be connected directly to the machine via a defined interface (usually without attachment by additional sheet metal parts). This facilitates handling even more when the readychain harnessed energy chain system is being installed.

In the event of service, thanks to the Module Connect adapter, every service employee is able to disconnect the defective energy supply system and connect a new, already harnessed and ready-to-install energy chain. With the adapter this is possible quickly and easily without the need of basic electronic knowledge.

But the adapter can show its advantages not only in the case of service, but also during the first installation of the readychain system. Here the installation time can be reduced by 80% as the adapter creates a coherent system of energy chain and interface and can be plugged into the machine in no time at all. The use of a ready-to-install module also optimises handling during maintenance – simply disconnect, reconnect, and it is ready.

The adapter is not only for use in automatic parking systems, but can also ensure quick maintenance in production or pharmacy systems for example.

The benefits at a glance

Tech up

- Fitted without additional sheet metal parts

- Flexible: simple clip fastening

- Safe: integrated strain relief and seal

- Suitable: configure the interface by combining individual housings into one connector

Reduce costs

- Save 80% assembly time

- Ready-to-install assemblies optimise handling

- For service: unplug it, plug it back in, done

_x000D_