Hanging installation of energy chains in machine tools

mkogelmann | 3. April 2020

In handling or in machine tools, energy supplies must be planned as “hanging” applications for vertical movement.

This is actually not a great challenge, but there are things to consider in planning and design.

Pivoting or fixed? Which connection method is the right one?

Pivoting mounting brackets have the advantage that when installation space is limited, the chain festoon dimension (“D” in catalogue information) can be reduced by the length of one link. In hanging installation, pivoting mounting brackets can always be installed if there are no additional forces in the longitudinal direction. In such cases, fixed versions or outer radius supports can be planned.

Of course they can be mixed, depending on the surrounding structure.

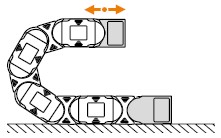

How much horizontal installation space do I need?

The minimum required installation space is twice the radius plus the outer chain height. Depending on chain size and radius, it is recommended that a little additional space (20-30mm) be left. It is also often a good idea to order an e-chain WITHOUT pretension. Just ad “NC” to the article number for the energy chain you want. An example would be 2500.05.075.0. NC.

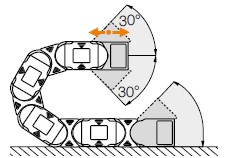

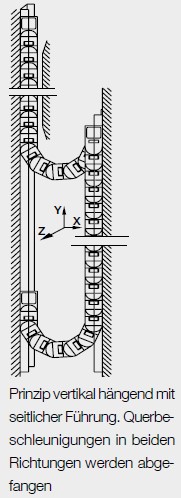

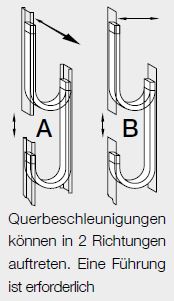

What if there are transverse forces?

If the energy chain is installed on a carriage whose travel is perpendicular to the e-chain, it must be able to handle the additional acceleration forces. In such cases, lateral support plates must be provided for if the e-chain overload is to be avoided. Forces applied, e-chain length, and additional filling weight influence support length selection. The undercut-design e-chain series are particularly suitable for such applications.

How should cables and hoses be laid and strain-relieved?

These two points are important and require special attention. Safe

strain relief and clear separation of cables and hoses are the basic prerequisites for hanging installations. Cables and hoses must be strain-relieved in such a manner that they can bear their own weight without slipping. The energy chain is merely a guide element and serves no support or holding function.

Suitable strain relief elements here include igus CFX clamps, the CFB strain relief plug-in system and tiewrap plates.

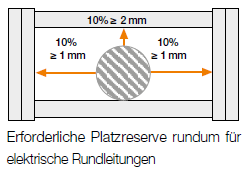

All cables and media guides must be laid neatly separated from each other, and space requirements are to be met as with other installation types.

For electrical cables, plan 10% of the cable diameter, but at least 1mm as free space on the left and right and 10% or at least 2mm over the electrical cable. For hydraulic hoses, it is at least 20%.