From prototype to volume production: how to choose the right method

Lars Butenschön | 23. March 2020

A variety of tools has been available for creating plastic components and parts since before the breakthrough of additive manufacturing processes such as laser sintering and 3D printing. But now there is scarcely any limit to the imagination. The only problem is that, thanks to 3D printing, dreams of plastic are facing a rude awakening. It often turns out that the desired object cannot be produced in volume with the planned method. “We will never be able to mill this undercut. And how are we supposed to do the contour without a corner radius?” “We can’t manufacture the surfaces like that.” Even small changes or elements that have not been considered in advance can severely affect tool and part costs later on.

Preparation is everything

Time and cost pressure often cause things that sound trivial to be forgotten during development phases. To avoid undesired correction loops and unanticipated costs, it is important to consider the limits and special features of the different manufacturing procedures in advance, during the early stages of component design and material selection. Let’s take a look at the most common procedures and their pitfalls.

An overview of procedures:

Additive manufacturing

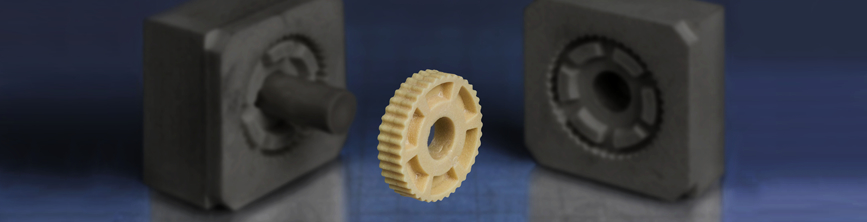

This generic term includes relatively new procedures such as 3D printing (FDM or fused deposition modelling) or laser sintering (SLS or selective laser sintering). In this context, additive means that the material is applied in layers until the part is finished. These methods require no tools or moulds and are therefore especially interesting for prototypes or small volumes.

Mechanical processing

Mechanical processing means using cutting tools on parts. It includes such processes as machining, drilling, turning and grinding. These processing procedures require previously programmed processing steps and carefully selected, suitable tools. Once the process has been set, the processor needs only to think about supplying and removing raw parts and monitoring the condition of the cutting tools. And nowadays, even that is automatically controlled by modern processing centres. That way, even large quantities can be produced economically. A further advantage is the large number of possible processing tools that allow very precise dimensions.

Injection moulding method

When you’d like a little more. Injection moulding is especially well suited to large quantities. After the initial investment in a suitable injection mould, several thousands of components can be produced in no time. The ordering party benefits from the strengths of mechanical processing, since the mould is usually produced mechanically. But there are printed or sintered injection moulds nowadays – and some of them are even made of plastic.

You should pay attention to these items early on in the design process

Expected quantity

The quantity is obviously derived from estimated or predicted sales figures, especially at the beginning. But you should still know in advance the effects these numbers will have on the price in the procedure in question, even if they vary. The rule of thumb is as follows: use additive manufacturing for small quantities, mechanical processing for medium-sized batches of a few dozen to several thousand pieces and injection moulding for large quantities. But there are exceptions. They arise from the following issues.

Stability and surface quality

Surface condition and stability during stress vary by manufacturing procedure. Components made with additive manufacturing usually consist of layers and are often rough. These layers are not equally stable in all directions.

Printed parts withstand loads better when they are applied perpendicularly to the layers than when they are parallel. The surface of printed components is relatively rough and uneven, but it can be milled over or chemically smoothed. Mechanical parts, on the other hand, can be smoothed with grinding, for example. Without grinding or milling, processed areas often have a grid-like surface. It is also important to pay attention to feathering. The bar stock material structure – the basic material such as plates and round bars – is stronger and more homogeneous than that of parts manufactured with additive methods.

In the injection moulding procedure, the processing of the steel injection mould leads to very smooth surfaces. The component surface is later covered with a sort of injection skin. At the same time, the premixed granules melt, ensuring that the material in the injection-moulded part is very homogeneous. However, you should make sure that, for example, wall thicknesses and radii are designed for injection moulding. That way, you can avoid such shape deviations as sink marks and torsions.

Part costs

There are big differences in cost. A 3D printer is ready for use relatively quickly. Connect the filament spool, prepare the print bed, upload the 3D model and you’re done. The installation and set-up costs are low. But the run time per part is long, resulting in a relatively high part price. With mechanical processing, the machine installation costs are often higher, but it takes much less time to produce the part – sometimes mere minutes. With injection moulding, the injection mould costs can be low or as much as high four or even five-digit amounts. But several parts can be manufactured at once within seconds.

The devil is in the detail

Unfortunately, these are all only general rules of thumb. Even small details can completely ruin the product design for manufacturing processes. The corner radius cannot be 1mm but 0.1mm? We need a different milling machine – that will be €200 more. The undercut must be right there? We need another slider in the injection moulding tool, and that will cost €1,500. Such cases do not happen every single day, but often enough. To be sure to avoid these issues, it makes sense to involve the processing partner or the relevant department in development early on.

The increasingly numerous offers of prototyping and processing service providers constitute a further – helpful – development. Free, easy-to-use programmes automatically calculate the costs of various manufacturing processes. The iglidur plain bearing designer enables you, within seconds, to determine the most cost-effective manufacturing procedure for plain bearings in the dimensions you need. In addition, you will receive suggestions for suitable dimensions from the iglidur product range in real time. In the end, using existing parts is almost always most the most cost-effective option.