Finding the right bearing: 7 essential criteria

Lars Butenschön | 4. January 2019

The various influences that affect the lifespan of a plain bearing are relatively trivial. It´s easy to imagine that a truckload of fine dust is rather less helpful for a long bearing life. Also, that 500 ° C ambient temperature can cause difficulty in choosing the right lubricant, results in few raised eyebrows. And yet, often times these essentials are overlooked in light of seemingly more important other requirements that not only the bearings, but the whole assembly have to meet. So what are the important factors? And which bearings are suitable for which influences?

Speed and movement types

A bearing would not be a bearing if there is no movement. That’s why this point is first in the list – Even though the question of “how much load can it support?” is usually the one that is asked first in real life. Strange actually…. But to the point. Of course, the decisive factor is the question of the way in which the movement takes place. Should it turn? Or just panning back and forth at a certain angle? Fast? Or slowly? What does “fast” mean for you? One revolution per 2 minutes? Or 500 per second? And if so, for how long? 1 second? 1 hour? Forever? A simple rule of thumb: Ball bearings or needle roller bearings are better suited for quick, permanent rotations than plain bearings. Sliding bearings are also suitable for slow to medium revolutions.

What is the force acting on the sliding bearing in relation to its cross section (ie bearing length x inner diameter)?

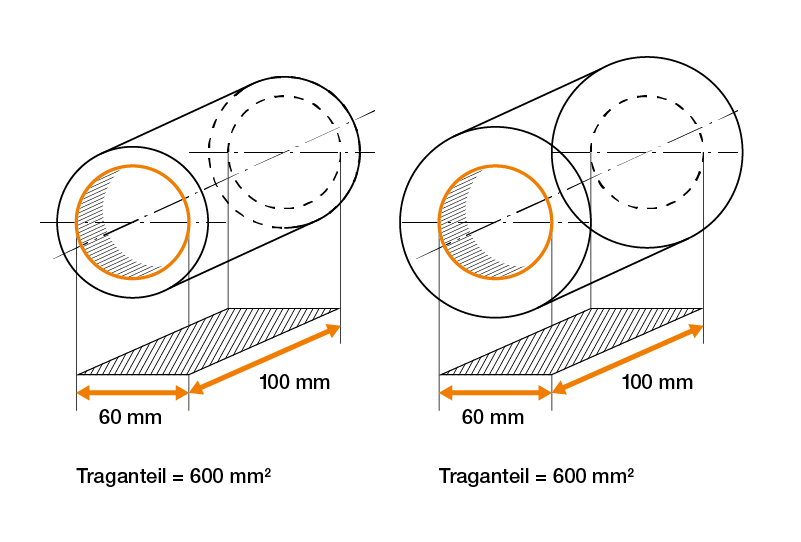

Already here, wheat separates from chaff – and not only as far as bearing materials go. What do I mean? This is where many misconceptions occur. In daily life, people put more attention on the load hanging on or supported by the bearing, than on the actual pressure resulting from it. Simply put: They don´t factor in the size of the bearing supporting the weight. Increasing the size of a bearing will dramatically decrease the pressure on the material. Frequently, the thousands of Newtons of load reduce to a surprisingly low pressure that actually affects the bearing material. In the end, there is the realization that it does not automatically have to be an expensive and heavy full metal bearing (another common misconception: thicker wall thicknesses = more load capacity) just because the loads appear to be high right away. If the bearing is sufficiently dimensioned, “softer” materials are also suitable, which are often much cheaper and lighter.

What kind of stress is it?

Without going deep into the dreaded mathematical problems of mechanics dreaded by many students: If it were purely for compressive strength (the capacity to resist pressure), most of the bearings would not be made of expensive metals or plastics, but of stone. Typically, loads at bearing points are not static (ie always the same) and often do not work in only one direction. They push and pull in different directions at the same time. They “shear” and “twist”, switch, swell and then shake off, shake or beat. The mechanical terms are “static and dynamic loads” for constant or alternating loads. Not only the compressive strength of a material matters, but also the tensile strength, shear strength and elasticity. Suddenly the hardest material is no longer the best.

Temperature

Completely unjustified, this point follows only in fourth place. Why is this unjustified? Because it’s not about mere speeds or tensile tests on load test stands when it comes to wear – and thus the service life. But for heat. Frictional heat. Not for nothing the so-called PxV value plays such a large (if not alone) Role. The resulting frictional heat determine the functionality of a bearing . The larger the product of pressure and the speed of movement, the greater the heat development. If more heat is generated than can be dissipated, the bearing heats up and wears out or falls out. Not only the actual heat generation affects the heat development in the bearing, but also the thermal conductivity of the bearing material, the shaft and the bearing support, as well as the ambient temperature. These factors have a fundamental effect on the selection of bearing materials and possibly necessary lubricants.

Dirt and dust

Basically, both depending on the quantity and condition is not helpful for bearings of any kind. No matter whether sliding, roller or ball bearings. Whether dry or lubricated. Nevertheless, since the various types of bearings “suffer” differently under these influences and protective measures are more complex depending on the design, this point plays a not unimportant role. Often elaborate sealing systems keep the lubricant in and the dirt out of the bearing. Another possibility is constant in-hole lubrication of the grease (which is also the reason why, for example, some grease greases out of the articulation points).

Contact with media

This point has nothing to do with the press coverage of bearings. Rather, this term refers to the umbrella term for chemicals and substances with which the bearing comes into contact with. Unsurprisingly, it plays a big role whether the bearing has to run under water or in gas or is cleaned regularly. In these cases, a closer look at tables on media / chemical resistance of the respective bearing materials is recommended. Often, however, there is no way around tests under application conditions. In general, lubricant-free plastic plain bearings play their main advantages here. They are corrosion-free and do not require lubrication due to volatile or externally supplied lubricants.

Counter partner

Finally, another often underestimated point – which is relevant, especially for plain bearings: plain bearings are usually designed so that a shaft moves inside of them, while they are themselves fixed in a housing bore. The type and surface quality of the shaft is of particular importance here. Not only the surface roughness, but also the hardness of the surface play a big role. For example: especially for “softer” steels or aluminum plastic bearings are better than those made of metal. Often even a superficial hardening is sufficient for optimal protection against wear.

Conclusion

Not every application requires detailed analysis of all these points. Nevertheless, they often play an important role in most bearing solutions, especially when combined. If these factors are combined, selecting the ideal bearing and reducing wear to a minimum on the basis of catalogs and datasheets alone gets difficult. In these cases, expert- or selection systems and personal advice from specialists often help faster and prevent cumbersome searches.