Energy supply systems in a hygienic ambience

Bastian Mehr | 31. March 2020

We often ask ourselves how we constructively implement the required energy supply systems in our plant. We often reach our limits and weigh up what is really necessary. In many places we get along completely without a guide. In some, however, it cannot be avoided. How often do we rack our brains and struggle to choose the right system? Simple energy chains can be found several times on the market. However, most are only suitable for certain applications. Here lies the real difficulty. The most diverse requirements must be met and these requirements are sometimes combined. The desire to deal with it for hours on end is usually absent, and daily working life often does not provide the scope for this.

Do I have to make compromises?

If I then also work in the food, packaging or beverage sector and move close to the open product, it quickly becomes a difficult undertaking. In this case it is usually necessary to weigh up which compromise I can or must make. Some systems have an excellent guidance function, others are clean and hygienic. However, as the requirements are becoming more and more stringent, it becomes necessary to solve these requirements in combination. Unfortunately it is not so easy.

Path of development

We have achieved exactly this balancing act and have developed a hygienic energy supply chain for this purpose that meets precisely these requirements. The demands on a system with focus on hygienic design guidelines are particularly high. We are operating in an extremely sensitive area and wanted to meet all the requirements that the market demands. We could not have done this any better without the help and support of some companies from the food sector. We have taken customers from the very front line who have strongly influenced us with their everyday problems and requests during development. Who could have told us better where the weaknesses and problems of the current solutions lie, so that we could focus on them? No one.

What are the requirements of an energy chain for food contact?

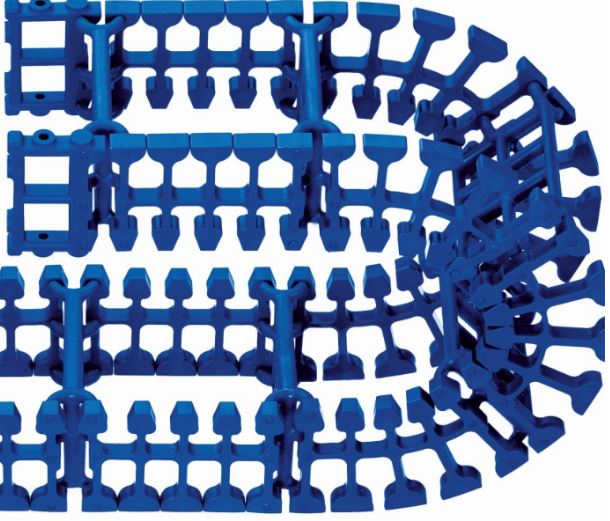

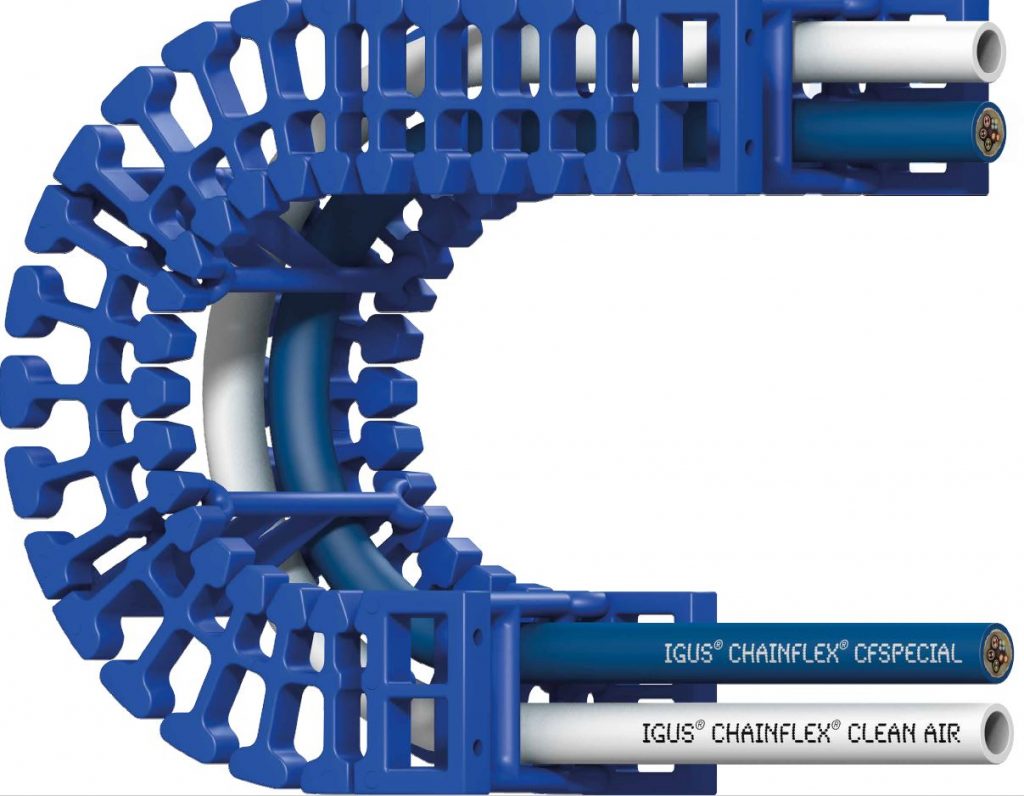

Whether it is a question of taking over the guide function of an energy chain, ensuring a design that is as open as possible and therefore easy to clean, or using materials that may be used in direct contact with food. We incorporated all these requirements into the development and implemented them with the TH3. Last but not least, the materials used are in compliance with FDA and EU 10/2011 and are coloured blue for visual detection.

The very clear focus was to have no dead spaces or undercuts in the system. Equally, corners that are difficult to clean are not welcome. For this reason, all corners were rounded and all surfaces finished with a slight radius. The connections of the chain are implemented by press-fit allowances and so also prevent potential jammed corners. We have designed the energy chain in such a way that it can be cleaned as easily as possible. “Just rinse with water and be done” was the goal.

More than hygiene is important

In the end, of course, the guide function was not allowed to be compromised by the strict hygiene requirements. To guarantee this, special materials were developed and extensively tested in the laboratory. In our own test laboratory with a floor area of approx. 3,800 sqm we have all the facilities to test our products extensively. This involves many different requirements. What is the minimum bend radius I can guarantee with the chain without expecting a reduction in service life? What accelerations and speeds can I achieve with it. The service life in the form of strokes/cycles is quite clear. But tests under the influence of temperature or moisture are also important. Ultimately, these tests, which we carry out thousands of times a year, enable us to make precise statements about our products, their service life and areas of application.

https://www.igus.eu/info/company-test-laboratory?L=en

Also available as ready-to-install complete system

We also offer the TH3 as a plug and play solution. We deliver precisely tailored and fully harnessed according to customer specifications with cable and connector. Ready for direct installation.

During construction we stuck to the Hygienic Design Guidelines as a reference and created a very hygienic design. Especially the open structure, which is easy to clean, is of great interest to the meat processing industry and its benefits are fully exploited.