“Data is the new oil” – How the igus test laboratory generates raw data that drive all smart plastics products

Richard Habering | 28. July 2021

“Tech up, Cost down” – this is the slogan according to which all igus materials and products are manufactured. The products are designed to extend the service life of machines and applications, eliminate maintenance and reduce costs. Our engineers consider workpiece quality and safety (that is, workpiece resilience and service life) as important criteria in development. Every igus product is tested thoroughly before it is made available for sale. To this end, we have been operating our own test laboratory since 1985. It not only is the largest test laboratory for tribo-polymers in the industry in terms of area, but also conducts the highest number of product tests and test procedures.

Our facilities for testing applications and materials cover a total of 3,800m². Every business sector has its own test laboratory, and we test some product areas together. For instance, 1,500m² are dedicated to testing chainflex cables in our own energy chains. For especially long travels, 2,000m² of outdoor space is available. iglidur plain bearings, drylin linear bearings, and our Low Cost Automation components are tested in an area of over 300m².

How many tests are conducted in the test laboratory every year?

Annually, a large number of tests and material examinations are conducted in the numerous test facilities:

- Over 15,000 tests in total, around 4,000 of them for e-chains and chainflex, and around 11,000 for dry-tech (rotating, pivoting, linear, tumbling, heated, underwater and so on).

- 450 test rigs for bearings

- 10 billion e-chain cycles

- 3,500 tested cables

- 2 billion test cycles for highly flexible cables

- 1 million electrical test records

- 400 customer-specific examinations

- Sensors on all test machines provide continuous measurement data

- Processing in the central database

What sort of tests are performed?

Energy chains are thoroughly tested. In linear movements of different lengths with travels of up to 240m and in vertical, circular or torsional movements. 53 test rigs on which 295 tests are simultaneously carried out to test e-chains for their stress resistance. In all, 4,100 tests totalling 10 billion cycles are performed every year. One million test data sets are collected every year in the various laboratories and test areas. They are saved in an electronic database and form the basis for further quality improvements for developed products. They also constitute the heart of the igus service life calculation. These well-founded service life predictions are one of the foundations of the smart plastics predictive maintenance concept.

What happens to the test data?

Use of testing data does not stop after development. Since 2001, we have been developing innovative online tools based on our test lab results database. This means a high degree of transparency for our customers, enabling them to find the most cost-effective, functioning solution to their problem. It also puts us in a position to make a meaningful maintenance prediction for every igus product.

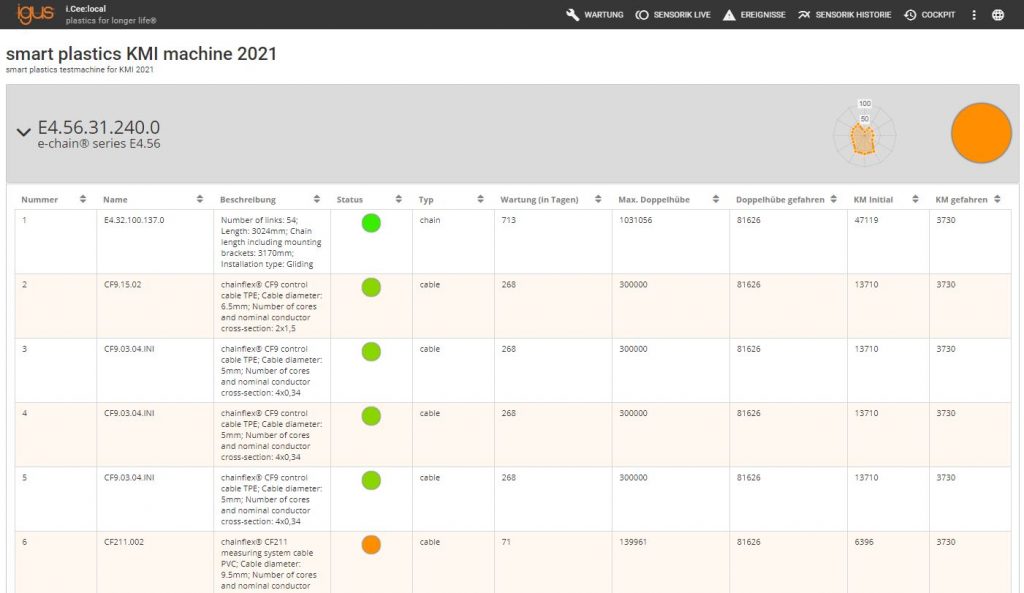

How do smart plastics products use this data?

Anyone who can make reliable, useful maintenance predictions requires more than Big Data, even in the age of digitalisation. To derive correct maintenance scheduling recommendations from the sensor data, we compare them with long-term empirical values from the igus® test database. And this product service life is one of the primary elements of the smart plastics i.Cee dashboard. At a glance, the dashboard shows the remaining service life of components equipped with smart technology. The output is in cycles or double strokes and days based on the travel speed or motion profile thus far. The maximum values, on the other hand, are empirically determined over years of test runs. So the data from the igus test laboratory forms the decisive raw material for all smart igus products featuring predictive maintenance.