Condition monitoring of the energy chain: with the new i.Sense EC.W sensor, it's never been easier

Richard Habering | 1. August 2022

Machine failures and downtimes are among the biggest cost drivers in industry. It is therefore important for maintenance personnel to act in good time to prevent unplanned stoppages. With the new i.Sense EC.W low-cost service life sensor from igus, users can now make their e-chain smart from just 248 euros. Thanks to real-time condition monitoring of the energy chain, maintenance is easier and more cost-effective over the entire service life.

We have also found that while online services are very popular in everyday private life, sensitivity to external data connections is very high in the business environment. For example, the IoT connection of a machine is often not wanted in production. However, the customer does not want to do without smart features and integration into existing control systems.

Low-cost sensors for easy condition monitoring on energy chains

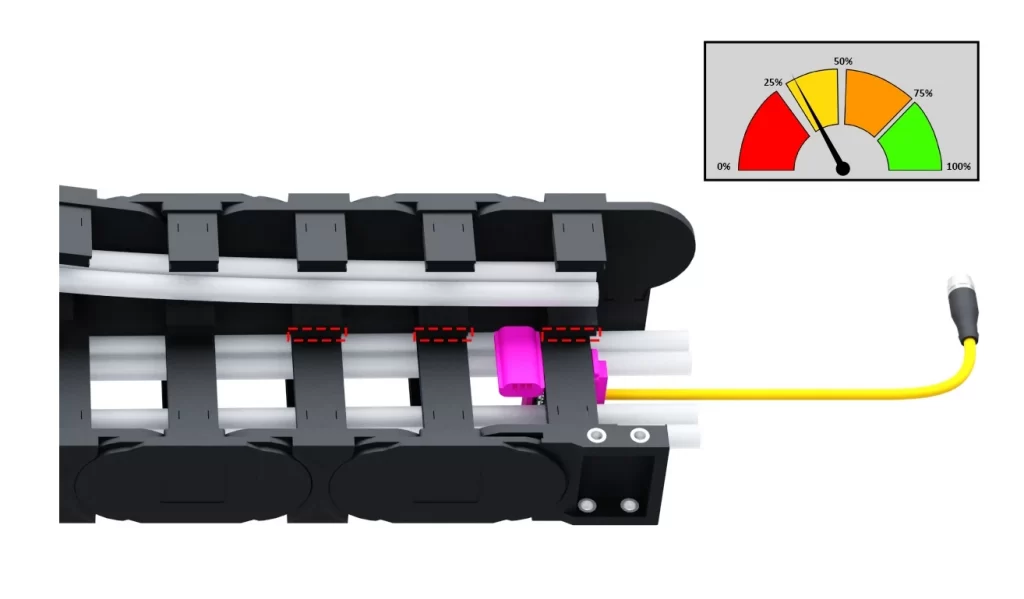

The basic principle of the new low-cost sensor system is simple: Conductive elements are incorporated into the high-performance polymers of almost all igus products at the tribologically stressed areas. Skilful geometric positioning of these elements allows clear statements to be made about product service life in the event of an electrical interruption or change in resistance. This information can simply be output to the operator via the system monitor and, for example, when the 25 percent level is reached, linked to the information about the pending chain replacement. The i.Sense EC.W sensor offers considerable added value, especially for harsh, dark, and dirty environments and highly frequented or hard-to-reach applications. It is mounted on the last crossbar on the fixed end side and records the current state of the chain’s side sections. The sensor measures the distance between the crossbars, which narrows in proportion to e-chain side section abrasion.

The range of condition monitoring products is extended to most energy chains

The low-cost sensor product enables cost-effective real-time wear detection from as little as 248 euros and, thanks to integrated, potential-free contacts, can be connected directly to the PLC machine control system without an Internet connection. The sensor, the cable and the evaluation electronics are included. Users also have the option of connecting the sensor to a wide range of networks and IoT systems via an i.Cee module and thus integrate it into a predictive maintenance concept. The service life sensor is available for the igus e-chains E4.32, E4.42, E4.56 and E4.80 – further sizes for the E4Q, E2.1 and E2/000 series are already being planned.