Compact cable guidance for slewing gear on indoor / EOT cranes

Jens Göbel | 28. July 2020

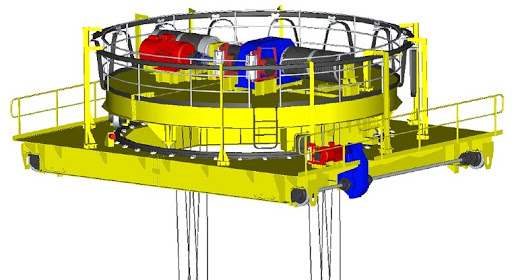

Slewing gear on the trolley enables to rotate the load beneath the crane girder. Such a relatively simple movement can turn into a design challenge. Especially, if a tight installation space limits the choice of possible solutions.

Festoon:

With the classic festoon system, the cable loops are usually hung on the outside of the slewing gear. The cables are guided with cable trolleys along a curved I-beam. The size of the angle of rotation determines the number of cable loops required. A low installation height on site can turn into an exclusion criterion for such a system.

Energy chain:

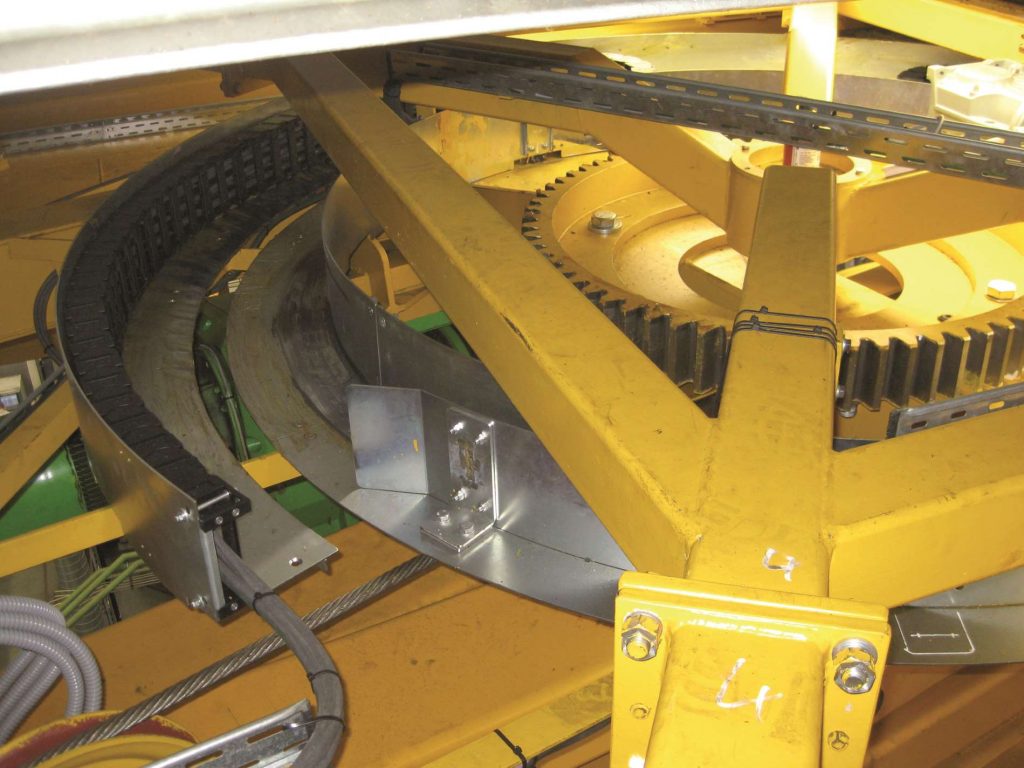

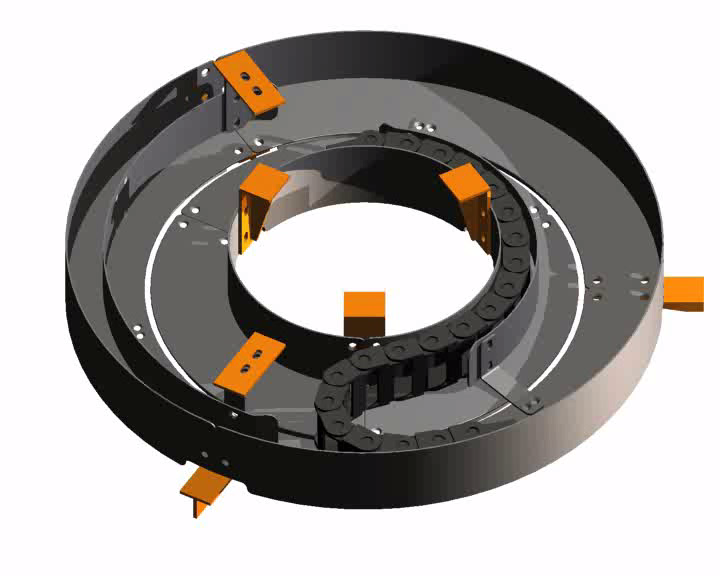

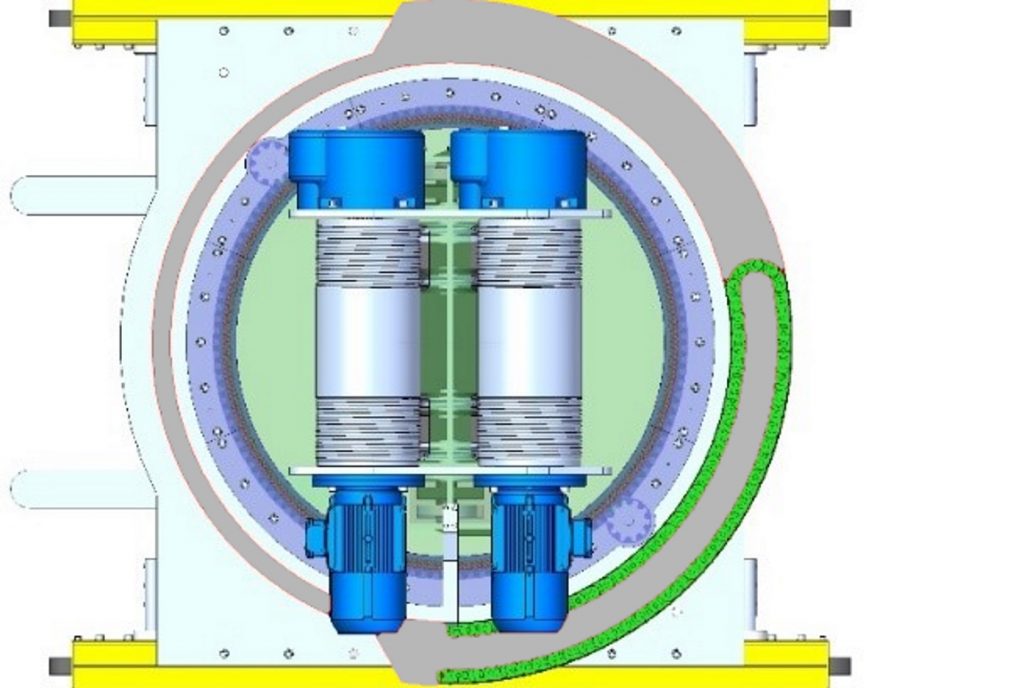

The energy chain system offers a space-saving alternative. Installed around the hoist, the chain system requires a remarkably small amount of space. A round guide trough helps to guide the side mounted chain. In this way, rotation angles of up to 540° and rotation speeds of up to 360°/s can be achieved. Larger cable packages can also be guided requiring very little space. This can be achieved by dividing the cable package and install two opposed running chains in the same rotary guide trough. However, such a rotary movement with the help of an energy chain places very special demands on the cables use inside the chain. The cables are routed inside the chain, but also bent very tight along the bending radius of the chain. It is highly recommended to use energy chain suitable cables, such as our chainflex product line, to ensure a long service life and to minimize equipment downtime.

3D configurator:

As the design of the slewing gear and the trolley are manufactured according to the local conditions on site and end customer requirements, individually adapted energy chain systems are required. With the help of a freely accessible online CAD configurator, individual 3D models of the required trough system, including the chain, can quickly be generated and integrated into the crane design. You can find the configuration of rotary chain systems in the CAD configurator under product groups / energy chain / configuration for rotary motion. Please take note that the 3D data provided is not suitable to generate manufacturing drawings.

Guide trough design:

Different applications and conditions on site require an individual design of the guide trough. For this reason, we have put together a modular system with different guide channels that can be used. Here we can assist you with our experiences. On our website you will also find 10 tips for a long-lasting rotary energy supply.

Maintenance:

In addition to the low installation height, there are also other aspects that speak for the use of a chain system. The maintenance effort and the associated maintenance costs of individual cable routing systems are often underestimated. The cable trolley of a festoon system has rollers with integrated ball bearings. These require regular lubrication. To maintain the festoon system, the complete crane must be taken out of service. In comparison, the energy chain system is almost maintenance free. There are no components installed on the energy chain that requires lubrication.

On our website you will find further examples and solutions for the cable guidance on EOT cranes, as well as the free softcopy of our EOT crane brochure.

We did not answer all your questions, or you have an application you would like to discuss with us in more detail? Make an appointment for a virtual consultation now

EOT Crane In India

Great article! The comparison between festoon and energy chain systems is clear and insightful. Loved the focus on space-saving design, reduced maintenance, and the use of chainflex cables. The 3D configurator is a smart addition—very useful for custom EOT crane setups. Thanks for the valuable info!

Endeavourweigh

Great article! The compact cable guidance system for slewing gears is a brilliant innovation. It’s impressive how such solutions enhance efficiency and reduce wear and tear in indoor EOT crane operations.

Ganeshcrane

Thanks for sharing a helpful article on EOT Cranes in this blog you explain the working process. keep it up!

ABCOEngineers

Really a very helpful article thanks for sharing and keep on sharing!

ABCO Engineers is the Largest Crane Suppliers In Bangalore,Mangalore, Belgaum. Abco Engineers are the best EOT Crane Manufacturers in Bangalore, Karnataka. ABCO provides Cranes with Excellent Quality and the Wide Range of Crane services in Bangalore,Mangalore, Belgaum.Contact today for Complete Crane services in Bangalore karnataka.

Read more: https://www.abcoengineers.com/

Jens Göbel

Thank you for your positive feedback on our blog post. We will keep on posting new content on a regular basis.