Circular economy and product design

Ina Hartmann | 13. July 2021

Sustainability, and the circular economy are no longer mere trends or buzzwords, but urgent issues that drive people, the economy and public policy. Germany’s Chancellor Merkel, speaking at the 20th Annual Conference of the German Council for Sustainable Development on 8th June 2021, underscored the importance of sustainable development and a sustainability strategy that includes the circular economy, calling them “necessary“.

This article will explain some terms and provide an introduction to the circular economy:

- What is the circular economy?

- What does sustainable design mean for consumer products?

- How does sustainable design work in industry?

- How is igus implementing sustainable design?

- Using recycled material in production

What is meant by the term “circular economy”?

If you’re thinking “recycling”, you’re not getting the whole story. Recycling is one part of the circular economy; it is the process of reusing products instead of simply disposing of them. In classic recycling, materials are sorted by type and broken down into their constituent components, which serve as raw materials. A PET bottle becomes a new bottle or a sports shirt.

The concept of a circular economy goes further, encompassing a product’s entire life cycle, with recycling coming in at the end. Circular economy begins with the idea for a product, since design plays a decisive role. A product should be designed to be used for a long time and allow reprocessing and repair.

The important thing here is resource economy, closing energy and material cycles in a sensible manner and not tying economic growth to resource consumption.

Prevent waste from being generated in the first place

The rule is to avoid waste, especially for consumer goods and packaging. This includes plastic fruit bags, outer food packaging, and items such as B. shampoo bottles. Some solutions (perhaps not the final ones) are almost banal and affect design, which has already been mentioned: body wash bottles get bigger, and soap dispensers are made of recycled plastic. You may be thinking, “Isn’t making the bottles of recycled material the simplest approach?” One obstacle here is consumer acceptance. An attractively transparent or pure white bottle cannot be manufactured from recycled material. So a comprehensive, functioning circular economy depends to a substantial extent on individual attitudes, which may even be the most important factor.

Sustainable design for industrial products

When design is mentioned in the context of products for industry, function is the primary factor. Interior machine parts don’t have to be pretty, but they do have to function. Form follows function. For the circular economy, that means designing products so that they are efficient and can be used for a long time, and so that components can be replaced and repaired.

As a manufacturer of moving components, we constantly focus on component wear: every part should last as long as possible. That is why, in the area of bearing technology, around 50 materials have been developed that have been optimised for durability in various industries and under various application conditions. If a bearing bushing is worn, its design – usually single-part – means that it must be completely replaced, since it cannot be repaired. But in the area of linear guides, such as B. shaft guides, the liners used in the carriages can be replaced. The aluminium housing remains in use.

Problems can arise if selective improvements are not made, especially for large machine parts. Besides the resources involved, complete replacement simply costs a great deal of money.

For energy chains, which can be very long on crane systems or conveyor belts, replacing the entire system would have economic effects, since besides the material costs, the system would have to be shut down for an extended period if the energy supply needed to be removed.

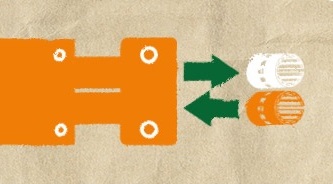

This problem can be solved with modular energy chains such as the igus E4Q. In this robust energy supply system, elements such as the clip crossbars are removable. This means that the crossbars themselves are replaceable, but even more importantly the chain can be opened easily without tools and an individual defective cable in the interior replaced. Another thing that makes the E4Q a special model is its new design, which conserves material without sacrificing functionality and stability. And less material/weight also always means less drive energy.

Using recycled material

When is a product green enough to be considered sustainable? And what options are there for parts and machine components? We are moving increasingly towards using recycled material in our own products. Ensuring consistent quality and function during this process is a challenge. That is why recycled material has been only part of any given product, and we consciously say that our high-performance polymers contribute to sustainability, not that they are sustainable. Within the circular economy, we are working on design, raw materials and recycling.