Can I lubricate plastic bearings with WD-40?

Lars Butenschön | 26. February 2019

It´s common knowledge, that together with duct tape, WD-40 is THE universal tool to fix anything and everything. While the former keeps everything in place when it shouldn´t be moving, the latter keeps things going that shouldn´t stand still. Many people think that these two tools will set you up for almost anything life throws at you. And the only thing that can further complement on that will for sure be iglidur® polymer bearings…..okay maybe that is a bit of a stretch :D.

But this post is not supposed to be about advertising iglidur® bearings, but about a topic that is brought up to me and my colleagues quite frequently. “Can I lubricate your bearings with WD-40?” “What if I apply WD-40 to get rid of that strange squeaking sound I sometimes get?” “Is your material resistant to WD-40?”. And of course the same questions arise for similar so called penetrating oils. Since WD-40 is the most common/famous of these, I will use it as an example in this post.

What is WD-40 and why would you want to use it? Does it qualify as lubricant for bearings?

First and foremost: If you aim to keep your bearing nicely lubricated at all times with low friction, wear and continuous corrosion protection – there are better options. WD-40 is a so called penetrating oil. It can go into the smallest of openings and cavities and even get under corroded surfaces. By doing so, it drives out corrosion, dust and grease. That way, most things stuck from corrosion or greasy dust and dirt get going again. However, without going too much into details here: due to being very runny / having a high viscosity, WD-40 doesn´t last very long, for example in bearing points. That´s why it is not able to provide a long lasting lubricating effect.

Why even bother with lubricating bearings with WD-40 then?

Despite the above mentioned issues, WD-40 can be useful for plastic bearings. The reason: Especially polymer bearings with integrated solid lubricant particles tend to have a so called run-in period. During the run-in period, the smooth injection molded surface of the bearing starts to wear off a bit, making it easier for the solid lubricants to spread between shaft and bearing. There are cases, in which this process is accompanied by temporary squeaking noises. Some people apply a bit of WD-40 during assembly of the bearings, to silence them, trying to improve running capabilities and friction in the process.

So let´s cut to the chase: How does lubricating polymer bearings with WD-40 affect their performance?

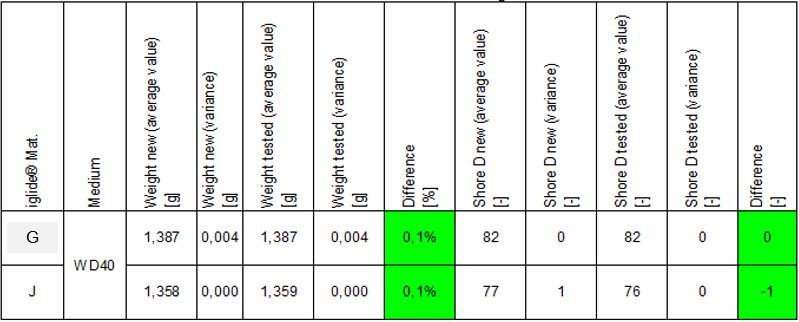

This question actually contains two. The first question targets the chemical resistance of the material. “Is the material resistant to WD-40?” For questions like that there are usually tables with chemical resistances. They are based on lab tests in which the materials are put into according chemicals for a certain amount of time. After that time, the bearings are tested for their mechanical strength and other abilities. Of course we did that with iglidur® bearings and gathered some results:

So they are resistant? And then what?

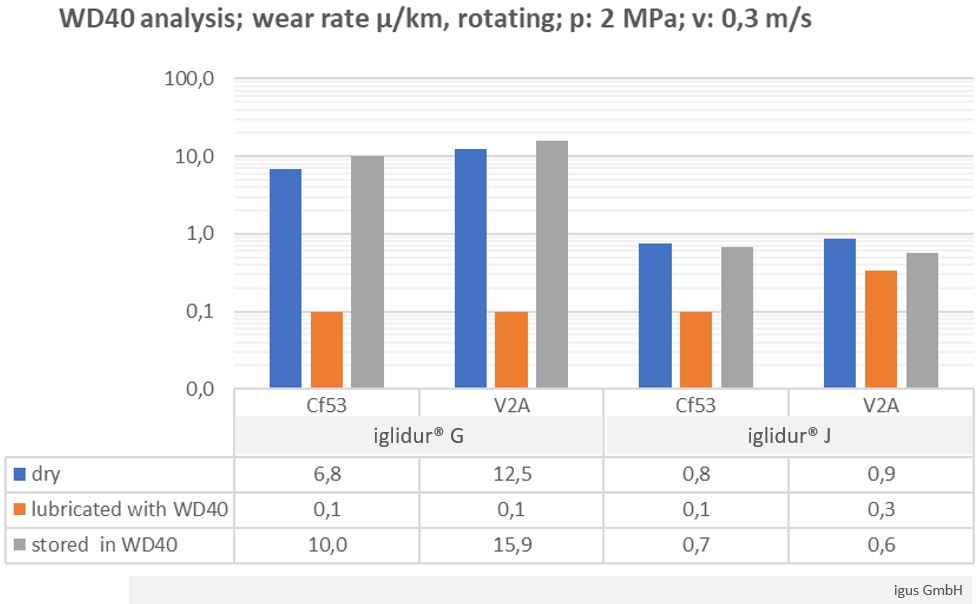

As you can see in the table, the tested materials show no significant deterioration in mechanical strength and absorbed only small amounts of WD-40. That means they are resistant. Great, right? But what does that mean for our bearings? Will they work better? Or the same? That is basically part two of the original question. Resistance is one thing, but the effect on the wear of the bearing – and therefore it´s service life – is another, often more important factor. To answer this question, we put the bearings to the test. Using our igus® bearing test rigs, with which we can simulate application setups for bearings, we tested three different scenarios. The first being a dry running application without WD-40 or any other lubrication (the best way to use iglidur® bearings). The second setup consisted of a initially lubricated bearing. That means the bearing was lubricated once during installation. The third setup was a bearing we stored in WD-40 before installation, so it would absorb the WD-40.

Conclusion

The best result was achieved by the initially lubricated bearing. However, I need to point out that we put quite a lot WD-40 on the bearing for the initial lubrication. The bearings didn´t show any significant signs of wear after 4 days of continuous rotation. In comparison, both the dry-running and the stored-in-WD-40-scenario showed an almost equal amount of increased wear. The reason for this is most likely that the amount of WD-40 that had been absorbed during the storage of the bearings was to small to be significant. But before you go buy a huge can of WD-40 or other penetrating oils of your taste, be warned: As I mentioned above, WD-40 tends to dry off quickly. After drying off, it leaves a small amount of residue that can lead to increased wear and noise after a certain amount of time. But this may be a story for another time.

SoccerLi

I will discuss WD40 with customers

Sophian

From my experience applying WD-40 on Metal Bearings give a very poor performance of the Bearings. With 1 time lubrication of WD-40 to igus Bearings I do not see significant effect, but a ask customer to avoid it.