Calculate surface pressure for plain bearings – this is how it works!

Lars Butenschön | 4. June 2020

One of the most important parameters for determining the correct plain bearing is the surface pressure that occurs in the respective application. Without them, one can actually only roughly estimate (sounds more technical than “guessing”) whether the plain bearing in question is suitable. As a matter of course, literature and the technical documentation of the manufacturers speak of the term “surface pressure”. But what does that actually mean? And how does it work? In this post I will show you how you can quickly and easily calculate the surface pressure for your bearing in everyday life.

It doesn’t start with the pressure, but with the surface!

The word surface pressure actually says it. The decisive factor is the surface. Frequently, the stressing of the bearings is reduced to bare loads. “That is, it’s got to hold about five tons.” But on how much surface area is this load distributed? Remember the principle of snowshoes. Even though these devices are only known from stories, as snow is becoming rarer in many places. Or think about tracked vehicles. Both tracked vehicles and snowshoes use a relatively large area to distribute the weight on loose or muddy ground. Neither the hiker nor the vehicle sinks deeply into the ground. Because the weight is distributed. The situation is similar with plain bearings.

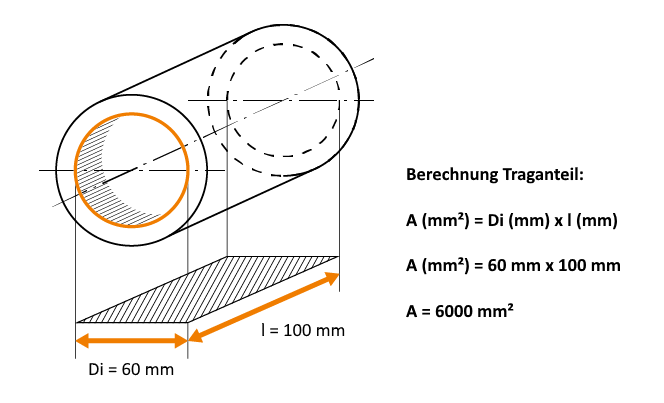

To perform the surface calculation – or more precisely, the calculation of the bearing area of the surface – of a plain bearing, we calculate as follows:

A (mm²) = Inner diameter (mm) x bearing length (mm)

The result is the inner cross-section of the plain bearing and the simplified contact area. It does not correspond to the exact inner surface of the plain bearing. Due to the cylindrical shape, this would of course actually be larger. In reality, however, not every part inside the bearing bears the same load. Both forms of calculation represent only an approximation, of which the simple calculation using bearing length and diameter is ultimately the more practical and accurate one.

Especially with plain bearings made of plastic, it is important that the load is distributed over as large an area as possible, since its compressive strength is lower than that of steel. What exactly is meant by compressive strength and its significance for the suitability of plain bearings is the subject of more than an additional blog post and goes beyond the scope of this one.

What else do we need to calculate the surface pressure? Right. The pressure!

We now have half the surface pressure. The unit for surface pressure is N/mm². So what we are still missing is the N. That N stands for Newton and is not really the same as weight, so is only mentioned in passing. A detailed explanation can be found on Wikipedia or in the literature. In practice, the weight that loads a bearing position is often converted by a factor of 10. Physically correct would be 9.81, for the mean acceleration due to gravity (also for those interested in physics: see Wikipedia). Meaning:

Correct: Force (N) = Weight (kg) x 9. 81

Practice: Force (N) = Weight (kg) x 10 = “Fits with adequate clearance”

In the best case, at the end, a load of the bearing surface will result in Newton (N) and can now be put into relation with the bearing surface.

Calculate surface pressure: p = F / A

The force just calculated is distributed over the bearing surface. This means that we divide the force by the calculated surface area and obtain the surface pressure. Of course, the connection is quite simple in principle. Nevertheless, it is very often omitted. Moreover, this principle is only the tip of the iceberg. Many other aspects of the day-to-day business of “plain bearing design” are linked to this. Edge pressure and the resulting bearing damage, the effects of reduced wall thickness, or the PV value and its pitfalls – to name just a few aspects, also have a very large influence on the running performance or even the suitability of a plain bearing.

We would be happy to advise you!

Regardless of whether you need support in the correct design of plain bearings or are still in the very early stages of construction. We provide consultation – by telephone, virtual visit or at your premises and together we will find the “most cost-effective solution that works”.

zubair

please explain in detail how to calculate stiffness of plain bearing

Lars Butenschön

Hello there,

thank you for your question. More complicated mechanical properties of bearings like the stiffness are usually calculated using FEM (Finite Element Method). Explaining this technology is stuff for another blogpost I´m sure. In a nutshell: It´s a complex calculation done using special software fed with data of the bearings material composition and the size/shape of the part. Only with these specific parameters you can calculate the stiffness for a certain part in a precise way.

Thank you and have a nice day,

Regards,

Lars Butenschön

igus GmbH