Cables in cold applications. What to pay attention to and what can happen?

Marco Thull | 20. April 2020

Cables have to withstand the most diverse external conditions today. This depends entirely on the areas and applications in which they are used. Today we take a look at what you have to pay attention to with cables in cold applications.

What does temperature-resistant mean?

Cables fit for use in extreme temperature ranges are referred to as temperature-resistant cables. This means that the cables can be used in these temperature ranges without enormous loss of service life.

Here, they can be also be divided into heat-resistant and cold-resistant cables. Temperature resistance is required in various branches of the industry. Heat-resistant cables are often used in metallurgy, steel or rolling technology. Cold-resistant cables, on the other hand, are often used in refrigeration and air-conditioning applications or outdoor applications where minus temperatures are to be expected.

Application example for cold-resistant cables

An example of a cold or air-conditioning application is a storage and retrieval unit in a deep-freeze warehouse in the food industry. This application demands a lot from the cables even at normal temperature due to long travel distances or small bend radii. Therefore the requirement is very high at low temperatures.

This is comparable to a top athlete. A long-distance runner, whose competition conditions are usually around 20°C, will achieve worse results in snow flurries and icy temperatures than a Nordic cross-country skier who achieves his best performance in minus temperatures. This is also the case with cables for extreme temperature ranges. These are adapted to the temperatures, just as cross-country skiers are adapted to low temperatures in snow and ice.

The right jacket material

To ensure the full performance of a cable at low temperatures, the choice of the right jacket material is crucial. We at igus can always decide which cable is most suitable for the customer’s application due to a high cable variety. This great variety consists, among other things, of four different jacket materials (PVC, iguPUR, PUR and TPE) for a wide range of mechanical or chemical influences. The jacket material also plays a very important role in terms of resistance to cold. So, our PVC cables are only suitable up to +5°C. In contrast, the PUR cables are resistant to cold down to -25°C and the TPE cables are permanently resistant to cold down to -40°C.

Jacket damage

The error pattern of jacket damage is often found in deep-freeze applications. Jacket damage describes damage to a cable’s outer jacket. The jacket becomes hard and breaks up so the stranding or shield can be seen. The reason in these applications is often the selection of the wrong jacket material. As soon as a jacket damage occurs, the cable must be replaced immediately, as the mechanical protection around the cores is missing.

A glance at the catalogue details suffices

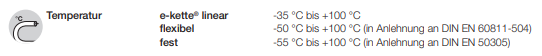

For each cable in our chainflex catalogue you will receive 3 different temperature specifications. These refer to the installation type of the cable. For the e-chain installation type, we describe a real application in an e-chain according to igus test criteria, because we have established that the following standard tests do not reflect the reality in the application. Here the test takes place at -40°C in our climate chamber. For the flexible application the data is based on a test according to DIN EN 60911-504. The cable is cooled down to test temperature. After the cable has been subjected to the test temperature for more than 16 hours, it is wrapped around a mandrel. After the removal, a pure visual inspection is carried out. The specifications for permanently installed cables refer to a cold impact test. A test weight is dropped onto the tempered cable. If the jacket is undamaged, this test is considered passed.

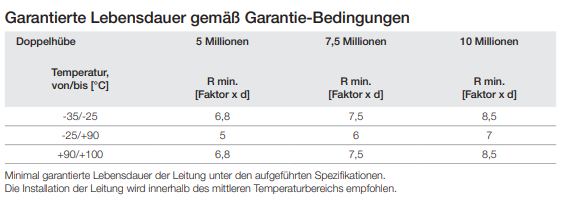

You will also find an overview from which you can see how high the guaranteed service life is in relation to the installed bend radius and the permanent temperature.

Guarantee by laboratory and tests

Due to the long-term tests conducted in our 3,800 m² large laboratory, our customers can always be sure that their igus cables will last. Only real application tests enable us to provide a unique guarantee of 36 months on chainflex cables. This goes far beyond the legally required guarantee of 12 months. In order to be able to maintain this even in extreme temperature ranges, we test the cold resistance of our cables in a climate chamber. Here our cables are tested under real application parameters in the energy chain. We can perform tests at temperatures down to -40°C.

Conclusion: do you also use cables in cold applications? If cold environments make you feel uneasy about your cables, then contact us!

\Ibrahim Mahmud

Dears

Kindly replay

Is it possible to use Medium voltage XLPE cables inside the warehouse type cold stores ? as the Electrical loads needs to install substation inside the warehouse to provide power supply to the ammonia refrigeration system.