Cable routing for lifting devices on indoor / EOT cranes

Jens Göbel | 26. June 2020

Lifting devices on indoor / EOT cranes, such as grabs, magnet spreader bars or other special lifting devices, sometimes require their own power and control supply. For that, the cables are guided from the crane girder to the lifting device. In order to be able to carry out the lifting movement of the device hanging below the crane, the cables must either be coiled up on a (motorized) cable drum or, with the help of an energy chain, stowed away safely in a special basket.

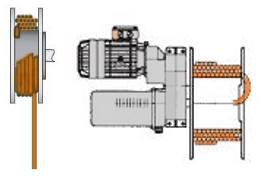

Motor cable drum:

A motor cable reel is frequently used for such an application. For the maintenance team, such a cable guidance system requires regular maintenance work, with the corresponding downtimes of the crane. Which components of the motor cable reel require this frequent maintenance effort? Firstly, such a system contains a slip ring, secondly either an integrated motor or at least a spring system. Each drive type ensures that the cable is kept under constant tension during the winding and unwinding process. The tensile stress puts a strain on the cable(s) used and has a negative impact on the cable lifetime.

liftband:

The liftband was specifically developed for vertical applications on indoor / EOT cranes with a lifting height of up to 13 meters. It is in principle a spiral energy chain that is connected to the crane girder on the one end and can be stored, for example on a spreader bar, in a specially designed basket, when the device is located underneath the crane girder. When the device is lowered, the chain is pulled out of the basket. The retainer belts attached to the system ensure that the energy chain is safely stored in the basket during upward movement of the lifting device. The system is very light weight and requires very little installation space on the lifting device, like a magnet spreader bar. The cables are routed inside the spiral chain, ensuring that they are not exposed to any tensile stress.

It is recommended to use energy chain suitable cables, such as our chainflex product line, to ensure a long service life and to minimize equipment downtime.

As the liftband has been deliberately designed using only components that require no frequent maintenance, the system is almost completely maintenance-free.

On our website you will find further examples and solutions for the cable guidance on EOT cranes, as well as the free softcopy of our EOT crane brochure.

We did not answer all your questions, or you have an application you would like to discuss with us in more detail? Make an appointment for a virtual consultation now

ABCOEngineers

Really a very helpful article thanks for sharing and keep on sharing!

ABCO Engineers is the Largest Crane Suppliers In Bangalore,Mangalore, Belgaum. Abco Engineers are the best EOT

Crane Manufacturers in Bangalore,

Karnataka. ABCO provides Cranes with Excellent Quality and the Wide Range of Crane services in Bangalore,Mangalore, Belgaum.Contact today for Complete

Crane services in Bangalore karnataka.

Read more: https://www.abcoengineers.com/

ABCOEngineers

Really a very helpful article thanks for sharing and keep on sharing!

ABCO Engineers is the Largest Crane Suppliers In Bangalore,Mangalore, Belgaum. Abco Engineers are the best EOT Crane Manufacturers in Bangalore,

Karnataka. ABCO provides Cranes with Excellent Quality and the Wide Range of Crane services in Bangalore,Mangalore, Belgaum.Contact today for Complete

Crane services in Bangalore karnataka.

Read more: https://www.abcoengineers.com/