Bearings for ATEX or explosive environments – A small guide

Lars Butenschön | 12. March 2019

Bearings for EX and ATEX – A small guideline

Trying to search for bearings suitable for environments with explosive atmospheres online is not easy. In fact, you will end up with more questions than answers. Which materials are suitable? What exactly is ATEX and what does it require? And what about plastic bearings? Aren’t they out of the picture anyway?

First things first: What does ATEX mean?

Warning: Boring definitions ahead: ATEX is a french acronym and means ATmosphères EXplosives. This acronym actually represents the ATEX 95 (equipment directive 94/EC, replaced by the new 2014/34/EU directive) and ATEX 137 workplace directive 99/92/EC. The directive ATEX 95 says, that every piece of equipment and protective cover assembly intended explicitly for use in explosive atmospheres must fulfill the criteria listed in the directive. I´ll spare you the details but we try to memorize: Being “equipment”, bearings would fall under ATEX 95 and there must not produce any sort of sparks, electric arcs or extensive heat. Therefore, many manufacturers of machines and equipment which need to work under explosive atmospheres ask for ATEX bearings.

Why are there no ATEX-certified bearings?

The catch here is the following. As stated above, ATEX only applies to “equipment” that is explicitly intended for distribution in explosive atmospheres. According to a VDMA study, bearings – being a universally applicable product – don´t fall in this category. However, if someone designs a machine for exactly that purpose and this machine uses bearings, the machine itself has to be tested according to ATEX. So here we are. Bearings don´t need an ATEX certificate. And I, working for a bearing manufacturer can lean back and live happy ever after. Of course that wouldn´t be very helpful though. In the end, all this definition stuff isn´t of great help for the aforementioned designer of machines that need to work in ATEX surroundings.

Even without falling under ATEX directly – the requirements for bearings are there

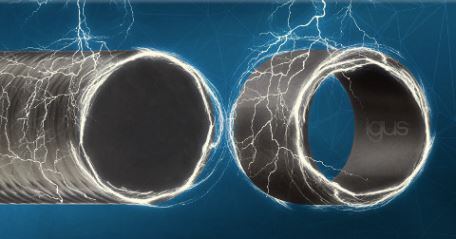

As we learned in the definitions, a machine certified for ATEX conditions must not produce anything being able to turn an explosive atmosphere into an exploding atmosphere. That means no extreme heat, no sparks, no electric arcs. More technical speaking, the main issue for bearings here is a phenomenon called ESD. Or electrostatic discharge. Did you get a little jolt or shock when touching your car door when leaving the car? That´s ESD for you. For bearings, ESD will occur when they isolate the moving parts around it from each other electrically. The result is an electrostatic charge that builds up in the components. When this charge is high enough or the charged components come in contact with a non-isolating (conductive) material, a spark or electric arc is generated – enough to explode an explosive gas or fine dust even. So in a nutshell: ESD in explosive atmospheres = not healthy.

The solution: Conductive bearing materials

As a manufacturer of plastic bearings, this is not a very pleasant insight of course. Typically, plastics are not very conductive at all, while metals are. But my mission of enlightening you as a reader and secretly trying to convince people to use more plastic bearings doesn’t end like this. Also fans of plastic bearings and everyone who doesn’t want to bother lubricating metal bearings and protecting them from corrosion can relax. There are conductive plastics. Of course not conductive enough for them to able to replace metals in cables but conductive enough to avoid ESD.

What does “conductive” mean anyway? When is a bearing “conductive”?

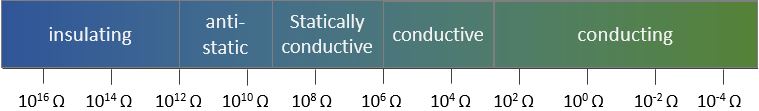

Conductivity begins at a resistance of 106 Ohm. Again, sparing you the details. let´s just accept for now, that this is a value describing how well electricity can go through a material. The lower the value (and therefore the resistance) the higher the conductivity. For a bearing to avoid ESDs, an electrical resistance of less than 1012 Ohm is required. Materials with higher resistance are called insulators. Fortunately for us, there are plastic compounds that reach 1012 Ohm and below. This is achieved for example by “mixing” metal powder into the plastic. “conventional” plastics are insulators and should be avoided in ATEX environments. Also: While metal bearings seem like a safe bet, you should be careful with using metal bearings lined with PTFE: Even the very thin layer of PTFE is enough to provide too much insulation for ATEX areas.

Summary

Whether or not a bearing material is suitable for use in ATEX environments can be taken from datasheets by comparing the electrical resistance or conductivity of the materials. And of course – when in doubt – ask your local bearing sales guy :).

JIm Sartain

Which of you materials are safe for ATEX?

Lars Butenschön

Hi Jim,

that´s what I tried to explain in this post :). In general our conductive iglidur® plain bearing materials are safe for use in ATEX environments. However, the plain bearings have to be certified according to ATEX standards after they are put in the machine/appliance they are to be used in, since they are a "component" and therefore don´t require an ATEX certification on their own. Also, we offer a range of ATEX certified linear guide systems and cable guiding systems that are ATEX certified because they are standalone systems.

If you have any further questions on this or other bearing topics, just let us know [Contact details here]

Kind regards,

Lars Butenschön