Ball bearings in semiconductor technology: why you should rely on igus®

Patrick Czaja | 21. January 2021

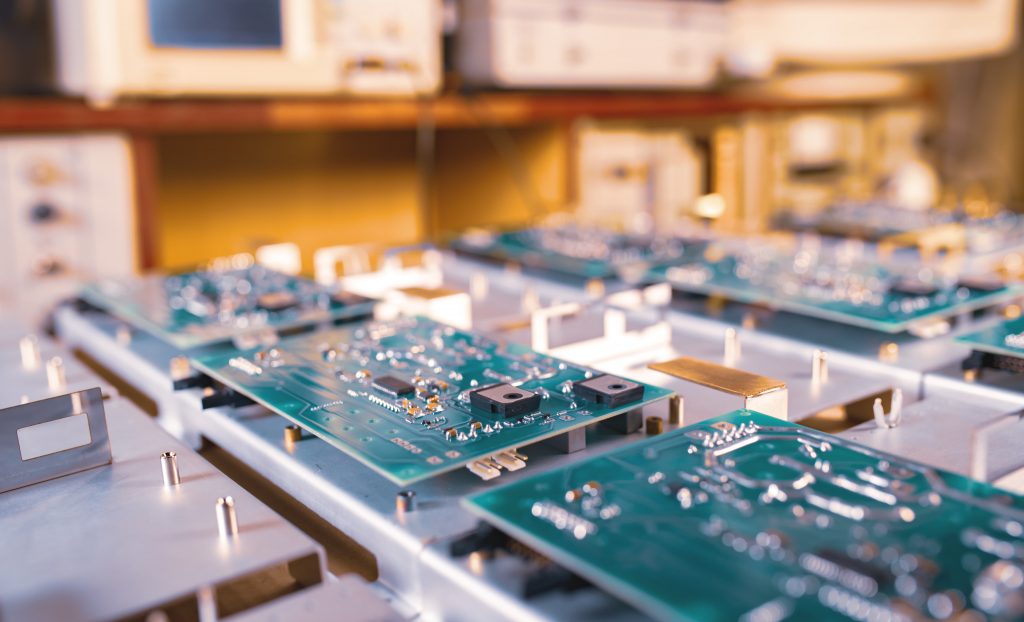

Semiconductor manufacturers face some challenges in the industry. Because they are always striving to achieve high productivity rates in their systems. Stringent and, above all, demanding application environments are commonplace in semiconductor technology, so components integrated into the process must function smoothly. In the etching of printed circuit boards or the production of LCD displays, for example, high temperatures, contact with aggressive chemicals or abrasive solvents are present in almost every production step. The bearing components used must therefore meet those requirements so that the plant operators/manufacturers achieve high overall system efficiencies. Therefore, only polymer ball bearings can be considered as ball bearings in semiconductor technology. Comparable solutions made of metal quickly reach their limits here.

Examples of ball bearings in semiconductor technology

The etching of circuit boards is essential in the entire production process of printed circuit boards. This process removes excess copper from the board, but the copper structures remain untouched. Usually the chemical is a strongly alkaline solution. So when etching printed circuit boards, chemical resistance and compatibility is the be-all and end-all. This is where our ball bearings made of high-performance polymers show the greatest advantage compared to their metal counterparts. Our ball bearings made of our own material C160 and A500 are the right solutions when it comes to ball bearing support in your semiconductor application. They are also characterised by high media resistance, easy operation and low moisture absorption. Our A500 polymer ball bearing can also be used in applications with temperatures up to 120°C.

With regard to LCD display production, transport plays an important role within the value chain. When transporting sensitive goods, users rely on ball tables that are made up of electrostatically dissipative components. This is because a current surge due to electrostatic charge, which is not dissipated by an insulating material, quickly leads to a defect in the LCD displays. Our ball rollers made of xirodur F182 are ideal for this application. Depending on the size, the polymer ball rollers transport up to 50 kilograms each and can be moved freely in all directions. Thanks to the material composition, the ball rollers come with electrostatically dissipative specifications. Ball bearings made of metal have an insulating effect due to the use of lubricants. For this reason, our ball rollers have a clear advantage.