Are plain bearings with thick walls advantageous in heavy-duty applications?

Uwe Sund | 24. April 2020

I would say that they are not.

Metallic plain bearings with relatively thick walls (conforming to DIN 1850, for instance) are used in many heavy-duty applications in agricultural engineering and construction machinery.

Typical bearings are steel bushings and plain bearings made of non-ferrous metals (bronze = copper + tin, brass = copper + zinc), but also of sintered materials.

Reasons for thick walls in metallic bearings

These bearings are often manufactured from solid material. If special machining (such as creating lubricating grooves) is performed on the inner diameter, it is obvious that a certain wall thickness is necessary.

It is also difficult for me to imagine that a metallic bearing with an inner diameter of 100mm and an outer diameter of 105mm (conforming to ISO 3547-1), can be pressed into a housing hole without great effort and without risking bearing deformation or other bearing damage.

Incidentally, iglidur plain bearings are very convenient to install. In an emergency – in the field, for instance – all you need is a hammer and a piece of wood …

Reservations about the use of thinner walls conforming to ISO 3547-1

At the beginning of many projects that involve replacing lubricated metallic bearings with maintenance-free iglidur plain bearings, I have serious reservations. Thick-walled metallic bearings have always been used. Now I show up and not only want to replace a metallic bearing with a polymer bearing, but also advise reducing the wall thickness. Either of those would be difficult to sell by itself.

iglidur polymer bearings – a long track record in agricultural technology

We have proven that iglidur plain bearings can replace metallic plain bearings in heavy-duty applications. There are many references supporting this proposition, and our products are also very well-established in agricultural engineering. I will demonstrate this with an example.

But what effect does reducing wall thickness have on wear?

I think that there are disadvantages only if the entire wall thickness serves as a “wear reserve”. In that case, a thick-walled bearing will of course last longer, given an identical wear rate.

But let’s be honest: is there an application in which wear in the millimetre range is tolerated? Not in sowing coulters, for instance. It would have disastrous consequences for the sowing pattern.

No customer accepts huge bearing clearances in his machinery!

And if a metallic bear is severely worn, things really get bad. There are almost certainly consequences for the shaft as well – the worn bearing can begin to seize.

To get to the bottom of things with respect to our iglidur materials, we have tested bearings of various wall thicknesses for wear.

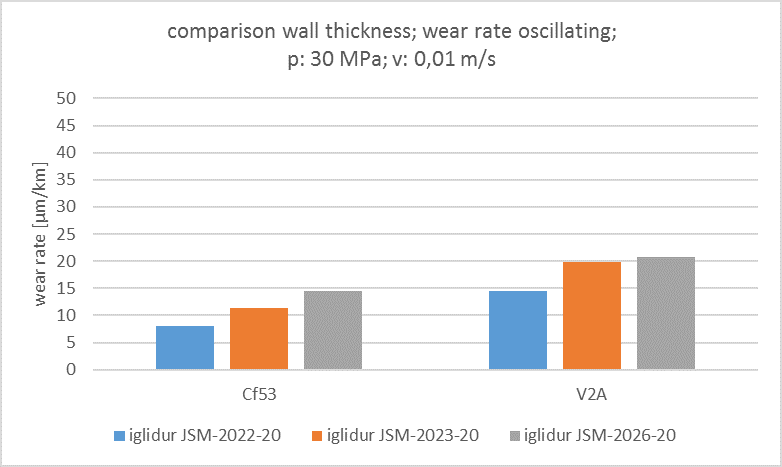

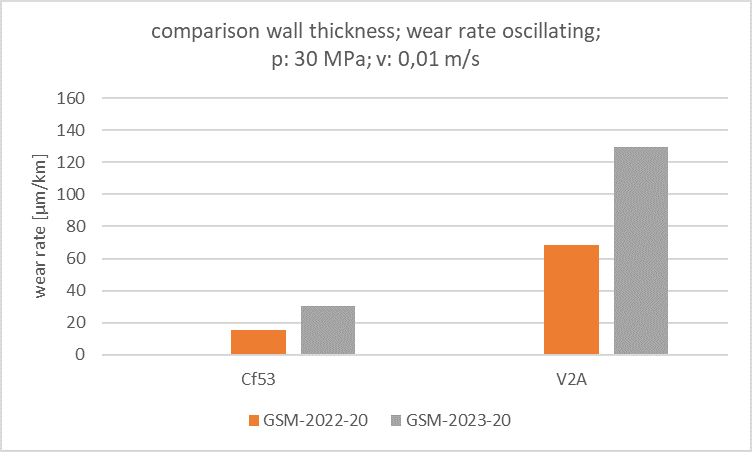

iglidur G and iglidur J were subjected to 30 MPa oscillating tests with various shafts.

Clear results

The thicker the wall, the higher the rate of wear.

(source: igus GmbH)

(source: igus GmbH)

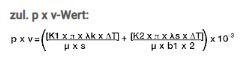

Among the causes of the somewhat increased wear is plastic’s low thermal conductivity. In applications with high p x v values, this can cause the material to heat up. The greater the specific p x v value in an application, the more critical.

Not to worry: most typical agricultural engineering and construction machine application speeds are low enough that negative effects are not expected. Nobody would try to raise and lower a fully-loaded front loader or wheel loader as fast as possible for an extended period of time.

If you want to know more about the p x v value, visit the igus home page.

(source: igus GmbH)

Typical obstacles for practical trials – how to overcome them

Because the support is designed for a larger outer diameter, the corresponding igus plain bearing of the same diameter will be too small. This can be overcome with an adapter that compensates for the missing wall thickness. The easiest thing to do is to rework the original metallic plain bearing’s inner diameter, even though it is certainly painful to re-purpose the expensive bronze bearing as a mere adapter.

Conclusion

Thick walls do not make a plain bearing more wear-resistant!

Other advantages of the thinner walls of iglidur plain bearings:

The bearings cost less, less material is used, and the injection moulding cycle times are shorter. Thinner walls also allow narrower tolerances.

So if you’re going to change from plastic to metal, it’s a good idea to change wall thicknesses at the same time.