What makes a self-lubricating polymer plain bearing so special?

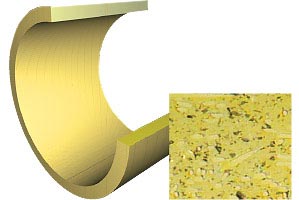

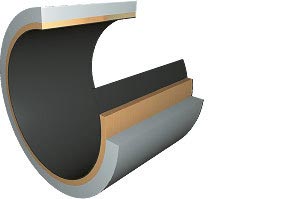

Some engineers are reluctant to consider plastic bearings in their designs. Perhaps they have become accustomed to metal or bronze bearings for years, or they simply doubt the suitability of plastic for difficult applications or environments. However, plastic bearings can withstand extreme temperatures, enormous loads and high speeds. One has to know the pros and cons of the options available. Self-lubricating polymer bearings contain solid lubricants that are embedded in tiny particles in the homogeneous material. In operation, these solid lubricants reduce the coefficient of friction. They cannot be washed out like grease or oil and due to the homogeneous structure they are distributed over the entire bearing wall thickness. Unlike a layered structure, the entire bearing wall thickness acts as a wear zone with almost identical sliding properties.

Most iglidur materials also contain reinforcing agents that increase compressive strength. High forces and edge loads can be withstood.

Due to this structure, the iglidur plain bearings can be used on many different shaft types – even on the so-called soft shafts, depending on the load. Thus a cost-optimised combination can always be found.

iglidur bearings made of high-performance plastics must not be equated with bearings made of any standard plastic. You can accurately calculate the service life of iglidur plastic bearings using the specific application parameters. igus offers you an Expert system – comprising a special database, where you enter loads, speeds, temperatures and other application parameters. The system then determines the appropriate plastic bearing and its expected service life based on test data.

Martin Petrenec

Hello, I am lookin for plastic materials (suitable for injection molding?) for plain bearing of ball joint which is self lubricating for extreme loading and temperature range -40 °C up to 120 ° C.