Why is an iglidur plastic bearing environment-friendly?

In the words of Kermit the frog: “It ain’t easy being green”. And even though he is only a hand puppet, Kermit is right – Today, many companies are doing everything they can to reduce their carbon footprint. However, transformation into a more environment-friendly company does not happen overnight. This is normally the culmination of a series of changes that take place over time in different branches of industry. What do iglidur plastic bearings contribute in this respect? Even though it sounds mundane, the use of lubrication-free plastic bushings can considerably reduce environmental pollution.

Four eco-friendly features of iglidur plastic bearings:

1. Plastic bushings do not need any lubrication – this protects the environment. It is estimated that just under four billion litres of industrial lubricants are consumed annually in the United State, of which approximately 40 per cent is released into the environment. Due to continual advances in the development of tribologically-optimised materials for plastic bearings, igus is able to offer eco-friendlier alternatives to metal bushings for more and more applications. Unlike metal and bronze bearings that require lubrication, every iglidur plastic bearing has solid lubrication that is embedded in the material and therefore cannot be pressed out or washed off. This means that the bearings do not need any oil or grease – so no contaminants are released into the environment.

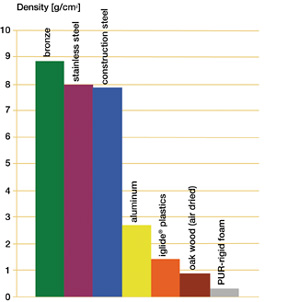

2. Plastic bushings are very light. The iglidur plain bearings can therefore also help to reduce the fuel consumption and carbon dioxide emissions of outdoor equipment, motor vehicles and aircraft, for example. The reduction in weight leads to lower masses and, as a consequence, to lower energy consumption.

3. The good chemical resistance of plastic bushings is another positive ecological aspect. Metals, in contrast, often have to be galvanised in an ecologically harmful galvanising bath in order to achieve this.

4. Less energy is required to produce a plastic bushing compared to a metal bearing. For example, the energy derived from around 15 litres of crude oil is needed to produce 1 litre of aluminium, and the energy from around 11 litres of crude oil is needed to produce 1 litre of steel. In comparison, only 1 litre of crude oil is needed to make 1 litre of plastic; and we assume that this value will fall even further due to the continuous development of plastics based on vegetable oils.