50 per cent savings with 3D printed spare parts

Maria Burkanova | 20. August 2020

Machines are expensive and so is their maintenance. This applies in particular to special machines and older models, where the procurement of spare parts is often difficult and usually cost-intensive. Often the required parts must be individually traced and produced. Costs and problems are not only caused by the always expensive custom-made production of individual parts, but also by the downtime of the machine.

Expensive spare parts for a winding machine

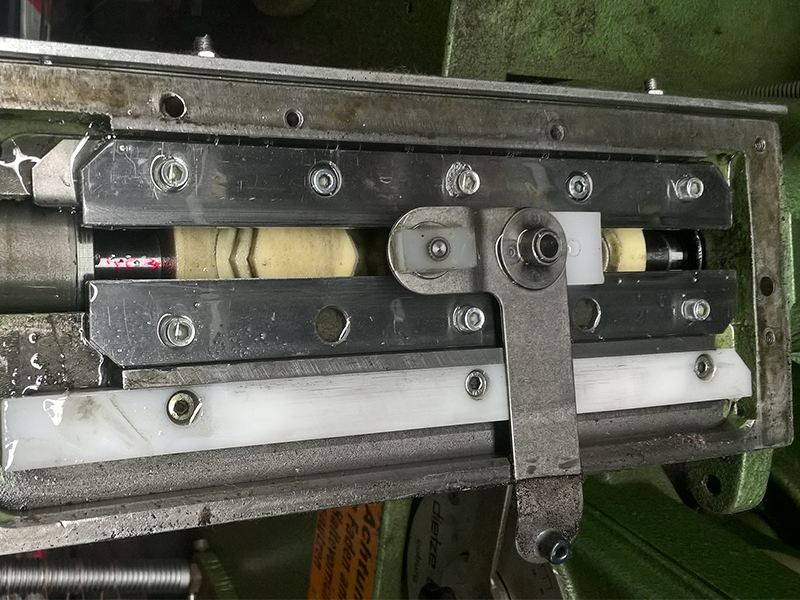

Conti Tech Schlauch GmbH also encountered this problem regularly when spare parts for their winding machine were needed. To wind up the brake hose thread, it is guided back and forth along the spool. A cross-threaded spindle was used, which ensured that the thread was laid directly or via a thread guide running through the groove. The intensive use of the machine quickly led to wear and tear on the moving components. The complex geometry of the cross-threaded spindle made the production of spare parts very cost-intensive.

The 3D printing service from igus had the solution: our engineers printed the cross-threaded spindle using laser sintering from wear-resistant polymer iglidur I3 within a few days. Now the winding machine winds again – more smoothly than before.

By using the 3D printing component made of iglidur I3, the company succeeded in considerably improving the sliding properties of the cross-threaded spindle and reducing the costs for operation and maintenance of the winding machine by around 50 per cent. The classical production was more expensive by factor 2 due to the complex geometry.

Fast and economical production of spare parts online

The laser sintering material iglidur I3 is distinguished by particularly low wear and high strength. Like all iglidur polymers, iglidur I3 also contains integrated lubricants, which eliminates additional lubrication of the printed components. In the case described, the maintenance technician has used additional lubricating oil to counteract the strong heating of the machine. If your application has similar requirements, you will find further information on the lubrication of iglidur bearings here.

The additively manufactured components made of iglidur I3 have detailed, exact surfaces, which is particularly important for the production of precise details – as is the case with the cross-threaded spindle, for example.

We print spare, individual and batch parts from iglidur I3 within one to three working days – without a minimum order quantity. The easiest and fastest way to order the drawing part you need is to use our online 3D printing service. Here only a CAD file converted into a STEP / STP document must be uploaded to immediately determine prices and delivery time and to order the required parts.

Of course, we are also happy to support you personally with questions regarding design, selection of the right material and manufacturing processes. For more information on wear-resistant 3D printing polymers, our manufacturing processes and other services, please visit our website.