Why plastic link rollers? Part 1

Bastian Mehr | 3. April 2020

The ravages of time have taken their toll, and you have decided to refine or optimise the application. Or you need to cut costs and save resources. The application has worked for years without any problems. It still does its job. But the time has come to rethink the entire system and optimise it technically. Customers have added many new requirements in the last few years, and others will be added soon. So there’s nothing for it but to change something. What has the greatest effect in the application, or where is the greatest need for improvement? The link roller. There were always reservations at this point. So why not look for a newer, perhaps better, solution here?

What types of link rollers are there?

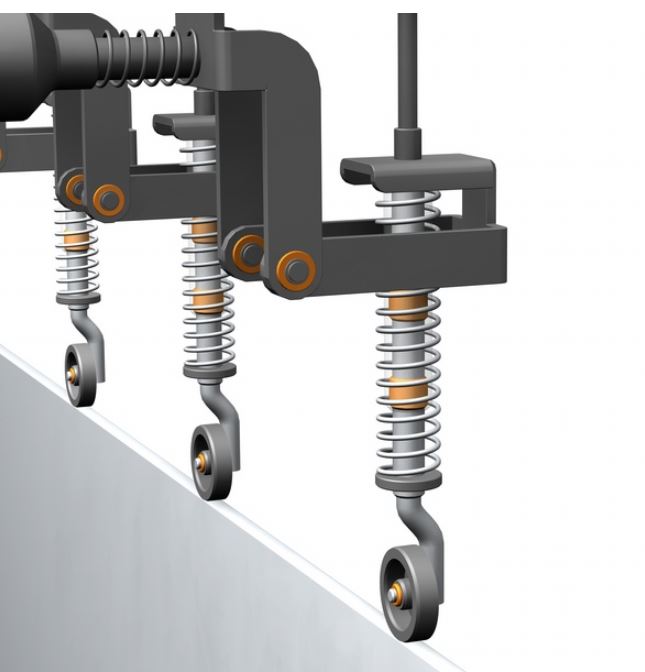

There are a wide variety of link roller types and application areas. They often do not greatly differ from one another. Either a link roller converts a rolling movement to a linear one in a link roller guide, or a pivoting movement is made. Roller requirements vary widely, however. One roller runs at high speed, sometimes under great loads, over long distances. Others, often very small ones, have a small movement radius and a much shorter running distance. The loads applied must not be neglected here, either. Another difference is the counter partner or the application in general. Some rollers operate in a wet environment and so are lubricated. Others have dry operation. There are vast differences in roller material and design as well. Some applications use metallic ball bearings/ball transfer units. The bearings might also be of brass, turned from solid materials. There are all the so-called 2K rollers. These are usually composed of a ball bearing and a plastic jacket. Solid plastic rollers are seeing more and more frequent use. And there is a good reason for this.

What are the advantages and disadvantages of the different rollers?

Metallic rollers consist of ball bearings with outer rings, usually convex. They are usually employed where high-speed movement is coupled with heavy loads. Such applications include filling machines, cappers, etc. Besides their advantages, they have disadvantages: one is that these rollers are usually very expensive, and another is that they need a precise counter partner that is also expensive. The link roller guide is a costly, mechanically manufactured component that must frequently be hardened. It must often also be lubricated to prevent wear to the link roller guide. This additional lubrication costs money and makes regular maintenance necessary.

Brass rollers used to be employed frequently in areas where running speed is secondary and the brass’s self-lubricating effect is sufficient. To a certain degree, they can take higher loads without any problems. But they are rotary parts that cost quite a bit of money. Another disadvantage is that they can cause wear to their counter partner (the axis on which the roller runs) and the link itself.

The high-end solution – the 2K roller – offers a very wide range of application areas. But there are limits here, too. Some of them come from the loads to be applied. The much more painstaking manufacturing process (the ball bearing is either moulded or set or pressed into a machined outer ring) raises costs significantly.

A solid plastic roller is a suitable compromise. The roller has the advantage of dry operation or water lubrication (depending on material). The roller is easy on both the pin and the link against which it runs. No grease or oil lubrication is necessary. It also requires less of the link. But even here, the material and the surface are important. But I will say more about this later. The decisive advantage is clearly the price. But it is very important to know the precise application parameters.

You can find out what to do next in Part 2 https://blog.igus.eu/why-plastic_link_rollers-part-2/