Why flexible cables are not a wear-resistant part

Stefan Wehrmann | 13. July 2020

“We replace the cables on the machine every six weeks. Well, that’s normal!”

We hear sentences like these time and again in our industry. Very few users are aware that this condition is not normal. Choosing the right cable makes the difference.

In this article I would like to explain why flexible cables are not considered a wear-resistant part. In addition, I will briefly point out the differences between standard cables and cables for the energy chain.

As an example, I will illustrate this with the optimisation process of a production line in which robots are used.

Small component, big effect

Back to the incoming statement of a customer. In his company, robots and other components within the production line were regularly maintained. So far, all normal.

However, what was unusual for us – as specialists for moving applications – was the fact that all cables were replaced at every scheduled maintenance. The customer stated that experience had shown that these were defective after about 6 weeks. Preventive replacement would avoid expensive downtime. In detail this involved two motor cable variants, one servo and one feedback cable. The cables were only selected according to electrical requirements and price.

After an initial analysis of the systems and requirements on site, suddenly there were completely different maintenance intervals. We could guarantee the customer a service life of at least 3 years. Subsequently, we were even able to add the probable total service life of the new cable solution to these figures. According to our calculations, this was about 14 million double strokes, which corresponds to about 6 years of operation.

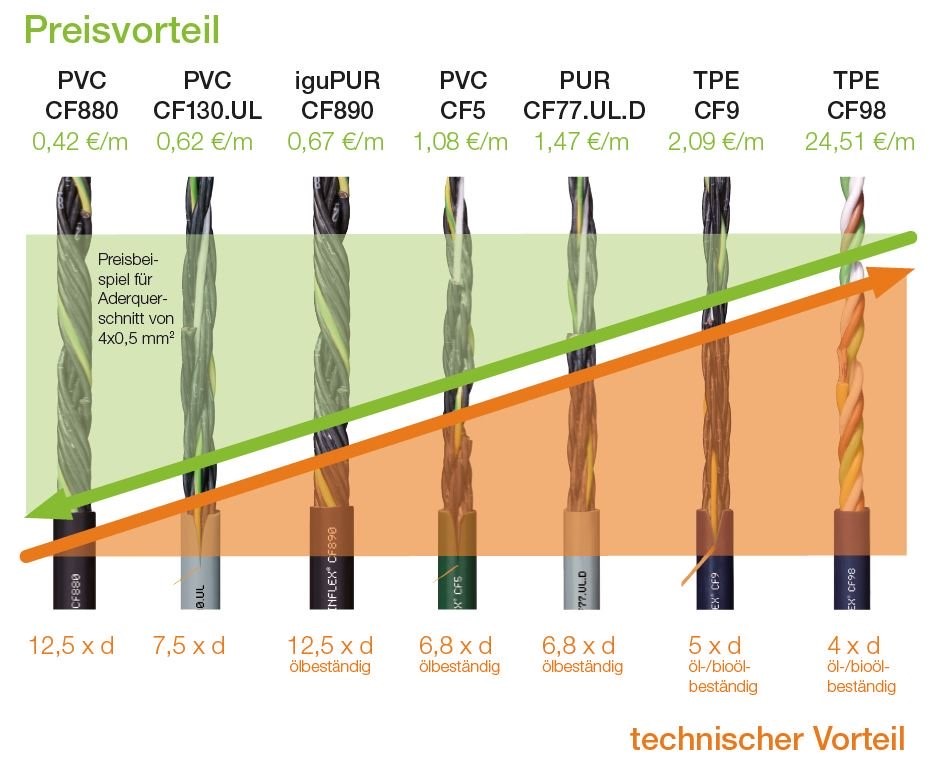

The slightly higher investment costs for the individual cable components became a minor matter for the customer. This was because the costs for the complete replacement of the standard cables were many times higher. If the trouble-free operation of the entire plant is taken into account, this results in a significant reduction in production costs.

But how is that possible?

Standard cable vs. Cable for the energy chain

In contrast to the previously used standard products, the cables selected now precisely match the requirement profile of the energy chain system.

Basically the following 7 design features determine whether a cable meets these requirements.

- Structure of the cable core

- Strand structure

- Core insulation

- Stranding

- Inner jacket

- Shielding

- Outer jacket

The strain-relieving core, for example, absorbs the forces that arise during a typical linear chain movement and otherwise may cause core ruptures. The specially stranded cores with short pitch length also reduce the risk of corkscrews and core ruptures.

A pressure-extruded and gusset-filling inner jacket for shielded cables, or a pressure extruded and gusset-filling outer jacket for unshielded cables, prevents movement of the cores within the cable when it is guided in the chain.

Furthermore, the special flat braid angles of the braided shielding ensure constant protection against electromagnetic influences.

The reason why cables are seen by users as wear-resistant parts is therefore only due to the wrong selection of the cable. If the structure of a cable does not fit the application, it will become defective more quickly and must be replaced regularly.

In the present case, the requirements of the small bend radius could be met by cables with an extremely abrasion-resistant TPE outer jacket.

In addition, we offered the customer free training for the colleagues in the assembly department to explain the special features of installing cables in energy chains in order to avoid possible errors.

Do you also want to reduce costs and increase service life??

We can help you, just contact us!

Conclusion:

Production processes can be clearly and easily perfected by using cables that are optimised for the application.

Everyone has certainly heard of the Toyota concept.

The five pillars on which this production principle is based are roughly equivalent to the points: “Synchronising processes”, “Standardising processes”, “Avoiding errors”, “Improving plants” and “Training workers”.

With the standardised use of cables optimised for the energy chain, systems can be specifically improved and errors avoided. Together with training on the correct handling of the energy supply components, the ultimate goal is thus achieved: eliminating waste, avoiding downtime.

Supposedly cost-effective wear-resistant parts otherwise quickly turn out to be hidden cost traps due to expensive preventive replacement or complex after-sales measures for delivered machines.