Why a self-sealing grommet does not provide strain relief.

Marco Thull | 18. May 2020

In this article, the self-sealing grommet does not play a role or only a very small one. I came across the (for me, new) term “self-sealing grommet” when I was looking for details about strain relief on the web. To cut matters short: self-sealing grommets are not used for strain relief and are therefore only suitable for fixed electrical wiring. The so-called self-sealing grommet is used in the area of electrical wiring and seals the entry points of cables and wires in electrical equipment against external influences such as foreign bodies and fluids. (source: Wikipedia)

What are strain relief devices and why are they indispensable for cables and wires?

In the area of electromechanics, strain relief devices are regarded as a means of mechanical protection for flexible hoses and cables. A strain relief device increases the service life of cables and hoses on which pull force is exerted. This pull force exerted on the cables/hoses is a form of mechanical stress. Torsion, bending or permanent back-and-forth movements are additional stress factors for cables and hoses.

As a result of the cable’s bending movement, it is compressed along its inner radius and stretched along its outer radius. If a connector has been attached to the cable (igus readycable), the wires can even be torn from the contacts in the long run.

Strain relief devices on energy chains

A strain relief device ensures that the pulling and bending forces that occur, are absorbed by the structure on which the strain relief device has been mounted, such as a drag chain or energy chain.

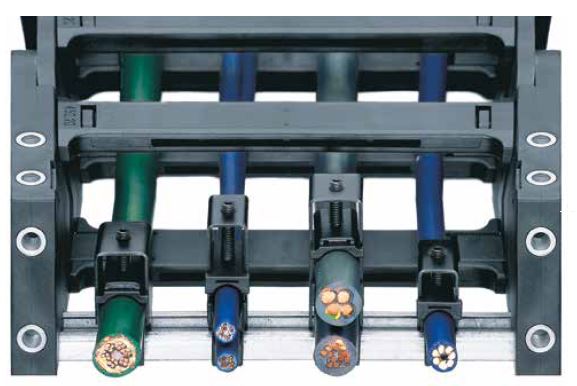

The strain relief device is a protective mechanical device that fixes the cables and hoses used in place so that they maintain their position in the energy chain.

Strain relief concepts

By using strain relief, the connection between a flexible cable and the end of the e-chain® is protected against mechanical stress. For this purpose, the cables are clamped or affixed by means of a screw fastener. The cable is clamped so that the length of the cable within the e-chain® remains constant, the cable also cannot be pulled in or out.

Strain relief can consist of standard elements or can be custom-made. In ideal cases, the cables should be secured at both ends of the e-chain® with strain relief.

Strain relief devices from igus® have been specially developed for use in e-chains® and dynamic applications. The combination of chainflex® cable materials and the touching polymer components of the chainfix-strain relief systems from igus®, have been designed for a long service life of the cables and for maximum holding force. For a wide variety of applications, igus® offers only the best solution in terms of costs and benefits, for example, the CFXL clamps for long travels and rough applications, the new CFU honeycomb strain relief system that can be fitted in seconds, or the chainfix CFN Nugget “strain relief system” for simple and cost-effective strain relief solutions. igus® chainfix strain relief devices have been tested under realistic conditions and have been used for years by customers all over the world.

To recap (according to Wikipedia)

A strain relief device is a protective mechanical device for flexible electrical cables and hoses.

The strain relief system has been standardised for non-stationary electrical equipment in accordance with EN 62444.

Components for strain relief are used in applications in which cables and hoses are subjected to intentional or unavoidable continuous stress, for example, in the case of energy supply chains.

Strain relief is essential for all industries and applications where cables are subjected to mechanical stress.

Sources:

²From user “Rogerhg” – Own work, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=37787037

³igus GmbH