Which jacket material for which industry?

Jan Arnoldy | 1. October 2020

We have already explained our different jacket qualities in another article. But, which outer jacket quality do I actually need for a cable in a certain application or industry?

I am frequently asked this question and therefore in this article I would like to show some common industry solutions as examples for the outer jacket qualities PVC, PUR and TPE.

In which industry is the PVC jacket material used?

Cables with a PVC outer jacket can be used in a variety of ways. Nevertheless, there is a widespread notion that PVC cables are suited to static installation only. This is not correct as there are many different PVC compounds on the market. It was very important for us at igus to find the right PVC compound for use in the energy chain. As a result, our specially optimised PVC cables have very good abrasion properties, are cost-effective and optimally suited for applications in dry environments at room temperature.

An example of such an industry is the timber industry. There, the cables are usually located in a dry environment, at room temperature and without oil influence.

But it is also the ideal outer jacket material for stone processing and many handling applications in the packaging industry. PVC cables are highly recommended even in car washes.

In which industry is PUR used as a jacket material?

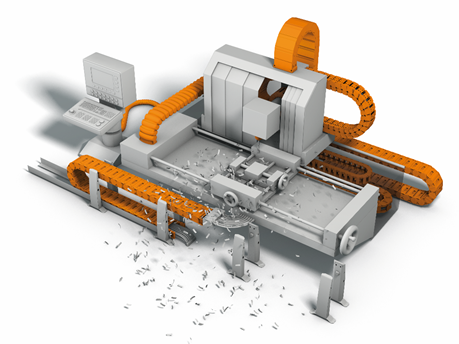

There are industries where the PUR jacket material is more suitable than others. One of the most important specifications of the PUR material is its resistance to oil. This property is required above all in the machine tool industry. There, the machine components often come into contact with coolants and other oils. Furthermore, PUR is characterised by the notch-resistance of the material. This offers the advantage that sharp metal chips, for example, cannot easily damage the outer jacket of the cable.

However, this jacket material also has a disadvantage: a PUR outer jacket has the most adverse abrasion properties among the materials mentioned.

In which industry is the TPE jacket material used?

The chainflex cables with TPE as jacket material are preferably used in applications with small bend radii. Furthermore, these cables are particularly suitable for high dynamics and long travels due to their high abrasion resistance. In addition, due to the wide temperature range covered by the TPE outer jacket material, applications can also be implemented in very cold temperatures. One example is storage and retrieval units in the deep-freeze area.

In general, cables with a TPE outer jacket can be found in a wide variety of applications in various industries. These include cold stores in the food industry as well as special vehicles and long travels. In addition, this material can also be found in applications worldwide with very low temperatures. This is why the TPE compound is used on most crane systems worldwide.

We hope we have given a good overview of the jacket materials suitable for use in the various industries.

Are you unsure which jacket material is the right one for your application? We would be happy to help you choose the right cable.