Where are plain bearings used?

Lars Butenschön | 6. August 2021

Where are plain bearings used? And when should you use metal plain bearings, and when plastic ones? It is not easy to give clear answers to these questions. The market is large and complex, and new products keep getting launched, shifting the limits of applicability and offering new advantages. But I will give you a rough overview here, show you the advantages and disadvantages, and present a few application examples.

Types of bearings: one part or several?

Wherever things move against each other, there is friction. Wherever there is friction, there is generally heat and abrasion. While heat means only that the temperature at the bearing point rises during the operating period and part of the valuable drive energy cannot be converted into kinetic energy, abrasion means wear and thus damage to the moving parts. Bearings are used to minimise these effects. They decouple moving parts from each other and ensure that if there is wear, it is to the bearings themselves. Bearings must therefore be replaceable. Their advantageous coefficients of friction also reduce efficiency losses and heat generated.

There are essentially two types of bearings. Multi-component bearings (ball bearings, rolling bearings, needle roller bearings, tapered bearings) and plain bearings, which consist of multiple components, but constitute a single part. Their simple design is also an advantage over other bearing types: plain bearings save installation space and weight. The primary disadvantage compared to tapered or roller bearings is the relatively high coefficient of friction. This means that they may increase the drive forces required, and given high speeds and heavy loads, they may generate heat faster.

Lubrication or dry operation?

There are various ways of further decreasing plain bearing friction. Some substances slide better than others. Lubricants are used to reduce friction as much as possible. There are liquid and solid lubricants. Liquid lubricants greatly reduce friction, but dissipate. Either they must be repeatedly re-applied, or great care must be taken to keep them at the bearing point. Solid lubricants are more resistant to external influences and can be incorporated directly as a fixed component of the bearing. Plain bearings can thus also be distinguished by type of lubrication. Some plain bearings must be lubricated, and some can operate dry. The latter are often made partly or entirely of plastic and can therefore not absorb the same mechanical loads as lubricated metal plain bearings.

Where are plain bearings used?

Given the properties listed above, plain bearings are used wherever something has to move. These applications range from simple hinges on a maintenance hatch to shock absorbers in mountain bikes to piston bearings in engines. So nothing would work in our everyday lives without plain bearings.

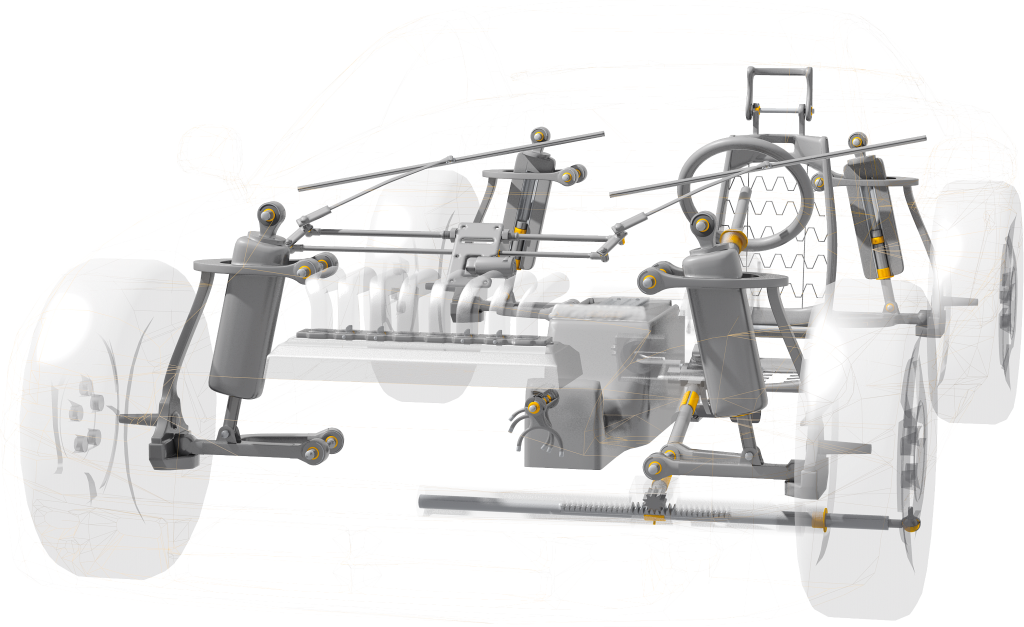

Where plain bearings are used: vehicles

Hundreds of plain bearings are installed in any vehicle. Not only in the engine compartment, but also in wheel suspensions, steering systems, pumps, brakes, pedals, and seats. Most of these applications require precision, quiet operation, low weight, and of course price minimisation. But there can be other requirements, sometimes very stringent, depending on the specific application. For instance, there must be as little play as possible in the pedal bearing. A bearing in a fuel or coolant pump, on the other hand, must be especially resistant to the respective fluids. Other bearings, such as door hinges, must be able to absorb great edge loads and must not cause the doors to sag, which would negatively influence the externally visible gap dimensions.

Where plain bearings are used: mountain bikes

A great many plain bearings are also used in the various shock absorbers, levers, and joints of a mountain bike. Much like vehicles, mountain bikes require low weight, tolerances, and noise. Great forces are also applied, and bearings are constantly subjected to dirt, dust, and water.

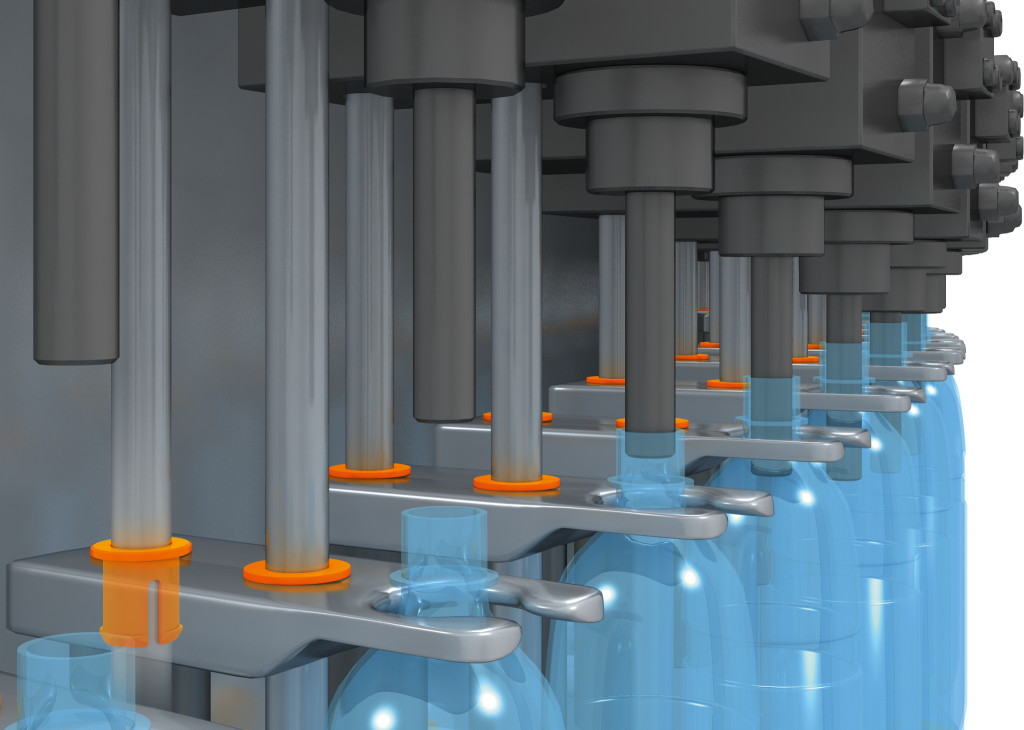

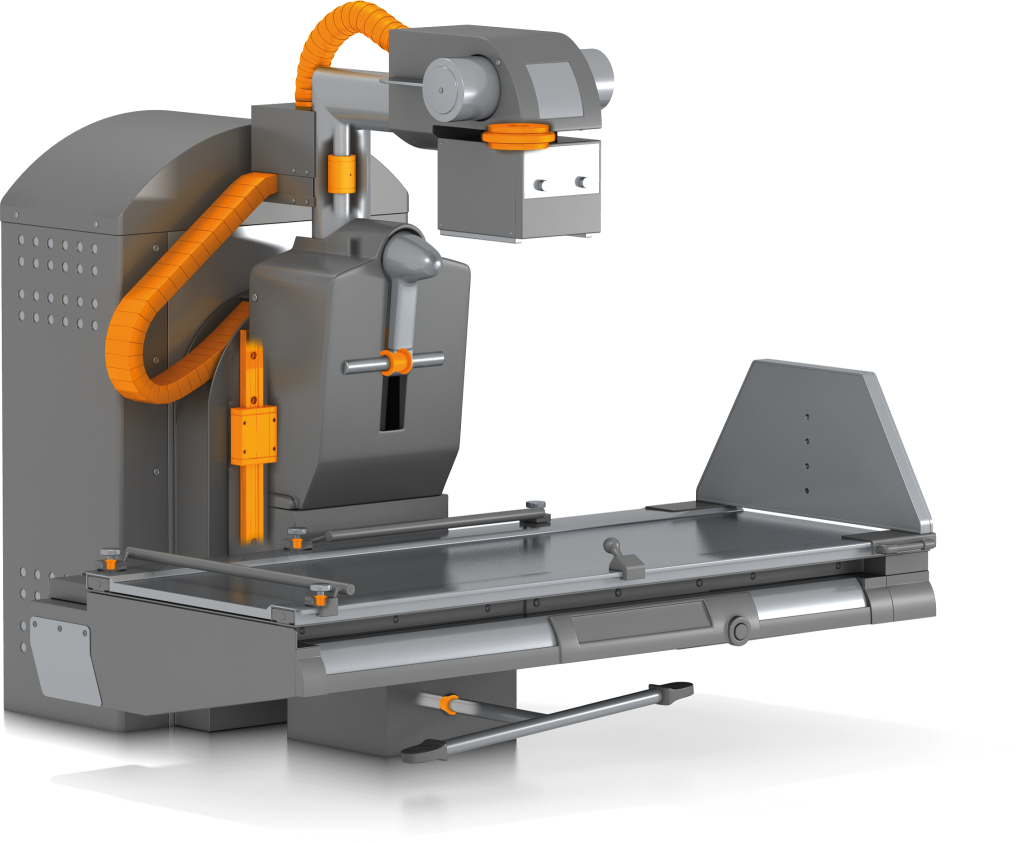

Where plain bearings are used: mechanical engineering

Mechanical engineering involves an almost unlimited number of different plain bearing applications. Just as there is a machine for every possible task, from a bottle-filling machine, in which plain bearings guide the filling nozzles, to conveyor belt deflectors to bearing bushings in drive chains. The application profiles are correspondingly varied. The requirements range from great precision to special certification for such items as contact with food to electrical conductivity to avoidance of undesired static charges.

Where plain bearings are used: medical technology

Plain bearings are also used in medical technology. The applications range from adjustment mechanisms in medical furniture and equipment to bearing support in hose pumps and dialysis machines. Frequent requirements are cleanliness, quiet operation, resistance to chemicals, and compatibility with the human body.

Where plain bearings are used: agricultural and construction machinery

Agricultural machinery and construction equipment often have very tough jobs. The moving parts of excavators, dump trucks, tractors, and various tillage and cultivation machines in the fields are subjected to very heavy loads. Dirt, dust, rain, and snow are especially hard on materials that are not corrosion-resistant.

Where are plain bearings used? Everywhere!

These are just a few areas of application for plain bearings. Have you ever wondered how your clothes dryer’s drum turns? Or why it takes so little effort to move your front door? Did you know that solar panels in the desert use plain bearings to follow the path of the sun? And did you know that, without plain bearings, your dishwasher could neither use nor pump out water? In a word, plain bearings are everywhere! Isn’t it strange that hardly anyone knows what plain bearings are?