What robot types are there, and what robot is the right one for my application?

Adriana Glazer | 6. April 2020

Time-intensive tasks are not always complex applications. Automating these applications saves time and money. There is a wide range of industrial robots on the market: linear robots, delta robots, multi-axis joints and SCARA robots. This article will give you a brief overview of the relevant robots on the market. When do I use which robot? What are the differences? Which robot is appropriate for my application?

The modular linear robot

Linear robots, also known as Cartesian or XYZ robots, are the robots most frequently used in the industry. They consist of several connected linear drive systems. They are often in the last axis equipped with an additional rotary axis.

The design is always very similar: there is a basic axis (X axis), a transverse axis mounted on it (Y axis), and a cantilever axis (Z axis). The guide profile moves along the cantilever axis, and the guide carriage moves along the other two axes. Linear axes are often combined with rotary axes. Linear robots achieve 3-4 degrees of freedom (DOF). The basic axis is often designed with two axes and an additional shaft that synchronises the two axes in parallel. This provides greater strength.

Linear robots are highly configurable and can be adapted to any machine design. They achieve a working volume of several metres for each dimension. They are very easy to program, since movement commands need not be translated to robot kinematics. (Movement command = actual robot movement) There are many different precision classes. Linear robots can be used in almost any load range. In most cases, they deal with loads of up to 200N (20kg). igus linear robots are usually used with the following application parameters. :

igus offers this type of robot complete with robot control system or alternatively with only motor controllers. It can also be prepared for customer motors.

The fast robot: the parallel kinematics of the delta robot

Delta robots, also known as parallel or spider robots, consist of three linear systems, all oriented on a central point. There are generally two delta robot setups:

delta robots with linear axes: the advantage of this variant is the capability of achieving greater process forces. It also has better safety and runs smoother under radial forces on the system.

Delta robot with dual-arm parallel kinematics: its lower mass allows greater speed and acceleration. Delta robots have a special design, are more difficult to program, and are therefore only available with a control concept. Equipped with an additional rotary axis, they achieve a maximum of 3-4 degrees of freedom (DOF).

Delta kinematics are optimal for use in pick-and-place applications. They are used for sorting products in the food, electronics and pharmaceuticals industry and for assembly processes with circular conveyors.

Parallel kinematics such as delta robots can reach speeds of up to 200 picks per minute with a precision of 0.5mm. At these speeds, you must make sure that peripherals such as grippers and vision systems can grip and release fast enough. The igus delta robot can be used at speeds of up to 60 picks per minute. It can sort one product per second with 0.5mm repeatability. This is a typical industry process time. The robot can be delivered with a complete robot control system (igus Robot Control) or with motor controls or prepared for the customer’s individual motor.

Flexible: the articulated arm robot

Articulated arm robots, also known as articulated robots, are designed like the human arm and normally have 4-6 degrees of freedom (DOF). To achieve a large robot range, the robots are often installed on a linear axis, the so-called seventh axis. Articulated robots can be used very flexibly. They always have a fixed design and cannot be integrated into all machines. This type of robot is normally used outside of the machine concept as a stand-alone solution.

Typical applications are palleting, gripping, inspection or welding. This type of robot can be found in all industries.

The articulated robot is slower, less precise, and more difficult to integrate than other robots, but can be used for any application. This type of robot can handle weights of up to 250kg with a precision of up to 0.1mm. The igus robolink articulated robot can be used with a precision of 1mm with loads of up to 3kg. It can implement applications with process times of eight seconds. One process is gripping and depositing parts.

The reduced articulated robot: SCARA robots

The SCARA robot has four degrees of freedom (4DOF). There are two common designs: one in which the entire arm is moved vertically and one in which the last axis is moved vertically. All other axes are rotating axes. The workspace for this robot kinematics is kidney-shaped. Typical application areas are assembly and joining tasks in the electronics industry. In most cases, it is used for loads of up to 15kg. Its design delivers process speeds between those of delta and linear kinematics: slower than delta robots, faster than linear ones.

igus has no standardised SCARA robot in its product range; such robots are configured individually for customers from standardised assemblies.

Which robot is the right one for my application?

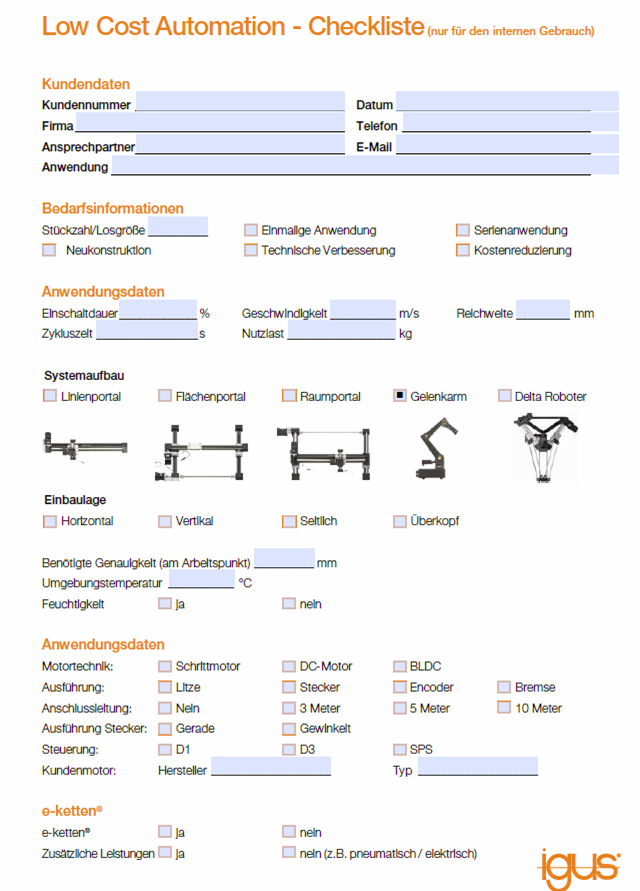

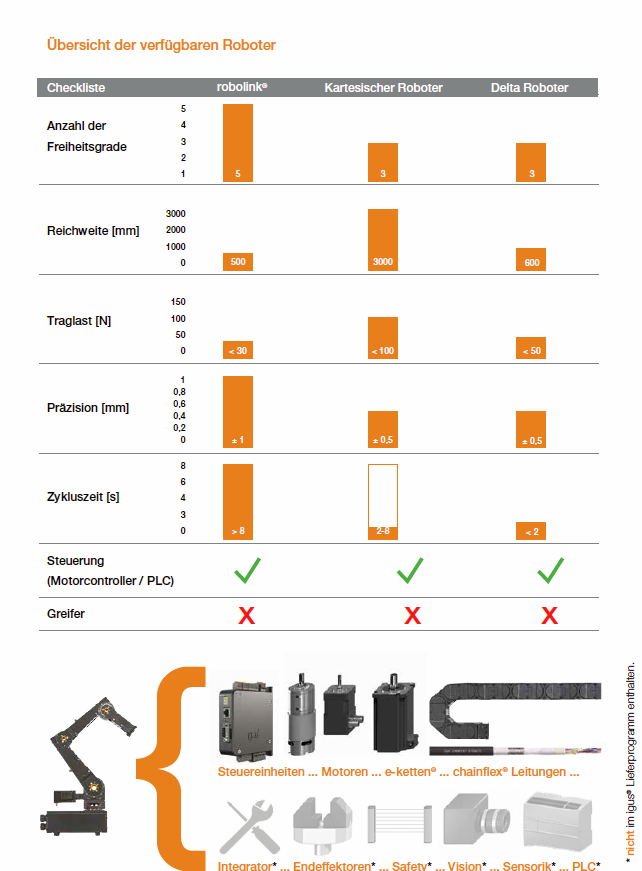

Fundamentally, there are many factors that influence robot selection. You can find them in our checklist. The most important influencing factors are:

necessary precision at the operating point

payload

process cycle time

range

degrees of freedom

It is important to select only the number of degrees of freedom you need. Each additional axis means programming effort, complexity, and susceptibility to error. Feel free to contact us. We will be happy to provide you with free of charge consulting on the kinematics best suited to your application.

About the author:

Alexander Mühlens

Phone: +49 2203 9649-8255