What requirements do energy chains encounter in automatic medication handling applications?

Beke Nieszytka | 25. March 2020

There are currently almost 19,000 chemists in Germany. The number has fallen faster and faster in recent years. For comparison, there were 21,441 of them in 2010. In the coming years, there could be 2,200 fewer chemists. The primary reason is that they are at a competitive disadvantage to mail order businesses.

Each individual chemist’s therefore has to do more in the space it has available – order more medications, store them and ship or sell them. Each of these processes involves a movement of medications. Since the volume cannot be handled manually, especially in delivery and retrieval processes, the issue of automated medication handling is becoming increasingly important. Automatic medication order picking systems can help here.

Automatisierungstechnik GmbH automatic medication order picking system

High requirements of medication order picking systems

Modular, space-saving structure

The systems must have a modular, compact design so that they can adapt to almost any on-site spacial conditions. Set-up and floor space vary widely from chemist to chemist. Only an adaptable system will be able to ensure supply.

Robustness & speed

Depending on the length of the on-site travel, the speed of such a system is up to 4m/s with an acceleration of 2.5m/s. In a classic chemist’s, there are about 300 delivery and retrieval processes per day. If the system is used in a hospital, for instance, that number can rise to 20,000.

Storage capacities in individual systems are between 9,000 and 60,000 packages. Depending on the composition of the individual systems, between 150 and 1,200 packages can be delivered and between 300 and 8,700 retrieved per hour.

Pre-assembled energy chains fulfil the high requirements

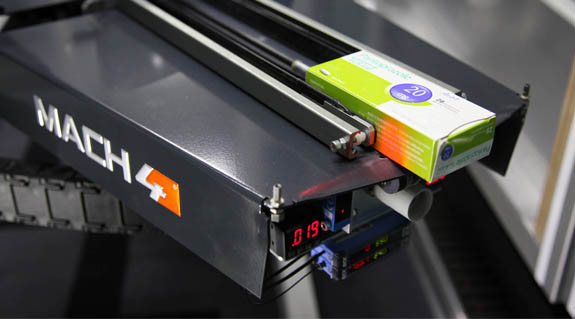

Mach4 Automatisierungstechnik GmbH medication order picking system

Wherever systems must be quickly expandable, the pre-assembled modules must be easily adaptable, and their installation and removal must be quick. igus readychain harnessed energy chain systems, have good performance, and not just because they are resistant and their components harmonised. They also minimise on-site installation effort, allowing them to be easily adapted, immediately ensuring smooth delivery and retrieval processes in the chemist’s.

readychains combine toughness and abrasion resistance, even at a high number of cycles, with low-noise, low-vibration running. It is still possible to install them with small bend radii, which is very important because it allows medicine storage space use to be optimised. Because of the very small chain link pitch and the resulting reduced polygon effect, there is scarcely any vibration or shocks. This means that the chemist’s customers do not notice the background picking processes at all.