What is productivity and how can you increase it?

Beke Nieszytka | 27. August 2019

Productivity describes the relation of the use of production factors (= input) and the production result (=output). A simple formula describes it as follows:

Productivity = output / input

You refer to an increase in productivity, if the same input results in a higher output. You also refer to an increase in productivity if less input leads to the same output.

To calculate productivity, different figures are put into relation. The comparison of produced amount (output) with the number of working hours (input) offers an easy start here.

If further factors affect input (e.g. general costs, pro rata company costs, used space, personnel, software, time, tools, machines, waste material, scrap etc.), these factors have to be considered in the calculation with the valid measurements. Therefore, companies should analyse their own processes and not eliminate value-adding activities, that do not have a positive impact on the end product (output).

The consequences of procuring resources for productivity

Here is a practical example:

Imagine you work in the purchasing department of a pen factory.

You buy the components of a pen – springs, inks and cases – from different suppliers so as to receive the most cost-effective option in the market for every component. That means, to obtain all materials for the pen production, you have to carry out three orders.

While the materials are being delivered, the factory cannot begin the production. Only after all components have been received, the factory can start assembling the pens. This means that waiting times can negatively affect the production process and hence productivity.

When you order the required materials, you should therefore ask yourself the following questions, amongst others, to find out at which point you can maximise your productivity:

- How high is the number of transport routes for delivery, storage etc. of the required components?

- How much time was spent waiting for required material or due to downtime in the production process?

- Apart from the price, what further advantages result from ordering from three different suppliers?

- Are the purchased materials of a reliable quality or do they offer a warranty?

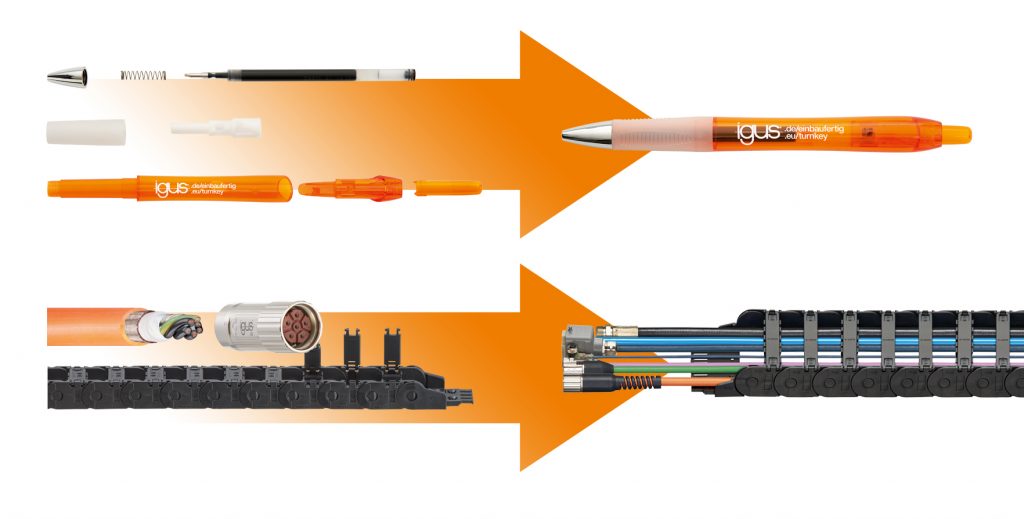

Would you buy a pen in individual parts?

Let’s stay with the pen example:

This time, you are working for a company where you spend most of your time in the office and you really need a pen for your daily work. Your current pen suddenly stops working, and you need a new one as soon as possible so that you can continue work.

Ideally, you do not have to put the components together in this situation to get a complete pen, but receive a completely assembled one. That way, you can carry on concentrating on your main activity, without having to interrupt it and invest time and effort in the assembly.

So, would you buy a pen in individual parts?

– The answer here is probably: No.

How igus® helps you increase productivity

The pen example can be used for our ready-to-install energy supply systems, so-called readychains®:

The advantage of an e-chain® is, similar to a pen case, that it protects cables during motion. No e-chain® works without cable and no cable works without a connection. So why should you buy individual parts and carry out the assembly yourself?

Application example of a readychain® system

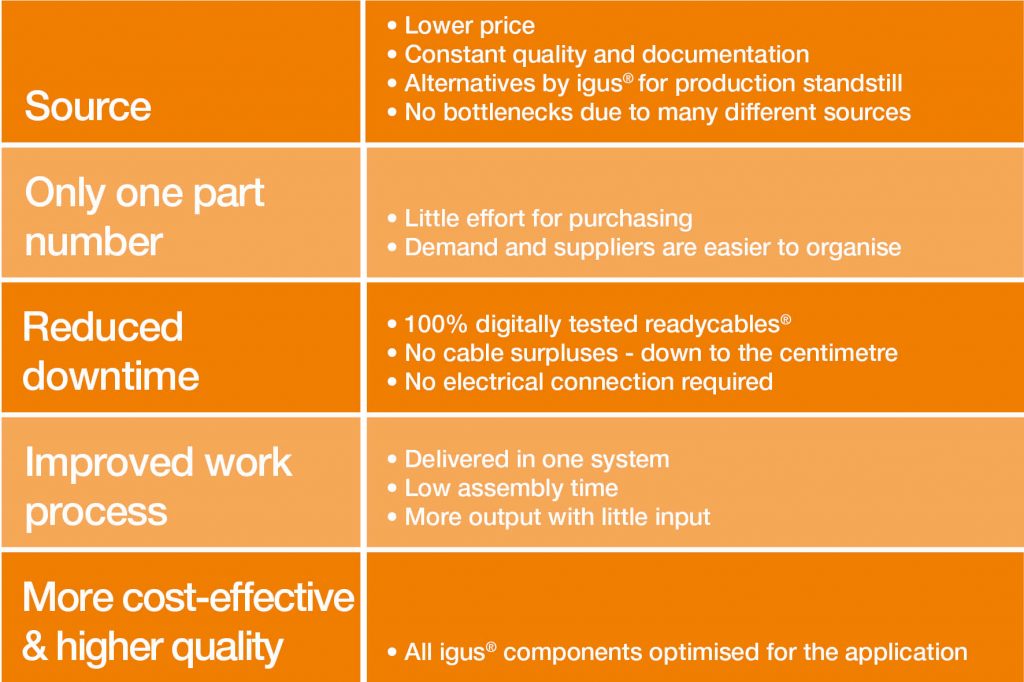

For years, a customer had bought different e-chains® and harnessed cables (readycables®) separately and assembled them in his factory. Thanks to a visit in his factory, we were able to optimise his working process by upgrading to a readychain® – a ready-to-install energy supply system.

You can order entire systems from igus® with only one part number and in addition save valuable assembly time. Thanks to the optimisation of the e-chain® and readycables® in use, which are adapted to the movement and special surroundings of the application, we were also able to reduce purchase costs for this customer.

Following the igus® motto: The most cost-effective solution that works ideally with your application, is the best solution.

For further information on readychain®, visit us here: igus.eu/readychain