What is Low Cost Automation and what do I get for my money?

Adriana Glazer | 18. May 2020

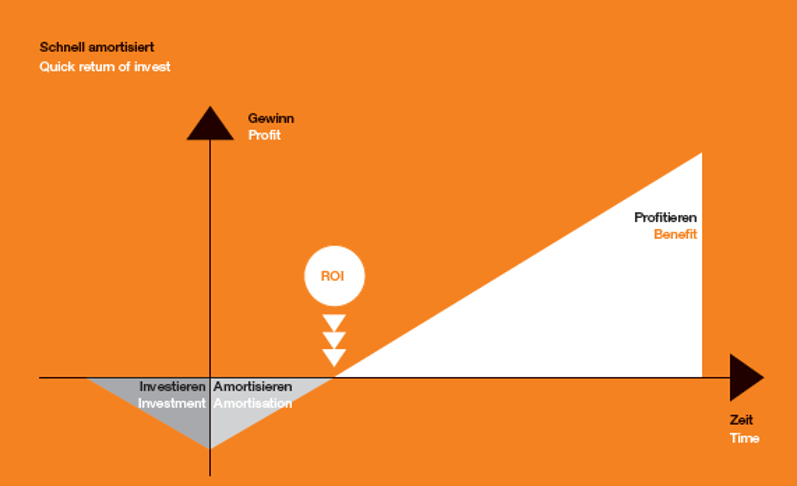

The name “Low Cost Automation” says it all. By definition, this means “…generating the maximum benefit with limited resources. ”

As an example of random bin picking, an article can be detected with the help of a camera and then grasped by a 6-axis robot. Alternatively, however, this article can also be grasped with a vibration slewing ring and a 3-axis linear robot.

If these two approaches are compared with regard to their complexity, it quickly becomes clear that the linear robot system with the vibration slewing ring is significantly simpler.

Let us stay with this example – the linear robot system is the more cost-effective robot and it is also less complicated – three instead of six axes… The vibration slewing ring referred to, however, also plays an important role. Apart from the robot, the periphery should also be uncomplicated and cost-efficient – this is the only way to achieve a fast return on investment.

An exact analysis of the application processes is therefore worthwhile. Costs can be saved by splitting complex overall processes into simpler individual processes. This is exactly the approach we take at igus when we create our applications and generate examples of low cost automation – Find out more in the following videos.

Automation of 2C injection moulding – lightweight robot places articles into the injection moulding machine.

Process for assembly of an energy chain – Pick & place with Delta robot

Process for assembly of an energy chain – 5-axis articulated-arm robot picks out energy chain links singly

But what Low Cost Automation solutions are there?

In our blog article, you can find out which robot system is most suitable for your application.

About the author:

Jacob Geber

Technical Sales

Tel.: +49 2203 9649-9840