What is an inner jacket?

Max Herrmann | 1. April 2020

The structure of a cable is very complex and, like many other issues, difficult to describe in a few sentences. The fundamental requirement of a cable is that it be as durable as possible. Today, we will look at the inner jacket’s contribution to meeting this requirement. It is an important component of a cable. We will also examine where it is located in a cable, what functions it performs, and how it influences the cable’s service life.

Inner jacket position

To explain the function of the inner jacket, we must examine it more closely.

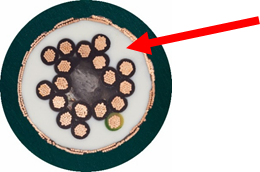

Where is the inner jacket located in the cable construct? We find it in high-quality cables for dynamic applications. There, we find it between the shield and the core structure.

Inner jacket function

An inner jacket separates the core structure from the shield. This ensures good core guidance and provides a secure foundation for the shield.

The pressure extruded inner jacket

At igus, we maximise cable service life by means that include pressure extruded inner jackets. “Pressure extruded” means that the material is extruded under high pressure until it reaches the spaces between the cores. The stranding construct is seated securely in the inner jacket.

The cores are guided in the longitudinal direction while retaining the necessary support in the transverse direction. This is similar to a train that runs on rails. In this comparison, the train is the cores and the inner jacket the rails. The rails point the train in the right direction and keep it in the right lane.

Inner jacket or taping with filler

An alternative to the inner jacket is the foil or fleece taping with filler that takes its place. This variant makes cable manufacture much simpler and reduces its cost. But an inner jacket in cables moving in an e-chain ensure a much longer service life, since the stranding element receives much better support.

Inner jacket for long travels

The pressure extruded inner jacket’s advantages are especially noticeable under great loads such as those that arise when travels are long. The disadvantage of a filler is that the fill element consists of soft textile materials. This does not give the cores much support. Movement also entails forces being applied to the cable, and that can cause the cores to come loose from their stranding. This results in an externally visible spiral deformation in the overall cable called a „corkscrew.This deformation can cause core rupture, and in the worst case can cause the system to fail.

Simple stripping despite pressure extruded inner jacket

Thanks to interwoven CFRIP threads, chainflex cables are easy to rip open in the longitudinal direction. The cores are not damaged during the process. The tear strip works much like a zipper. Just pull the tear strip and open the cable to the desired spot. This saves fitters and electricians not only time, but also additional tools. The cables are designed so that the string does not damage the jacket or cores even after millions of movement cycles.

Are you unsure which cable is the right one for your application? Feel free to contact us. We would be happy to help you.