Weight saving with energy supply systems

pwirth | 30. July 2020

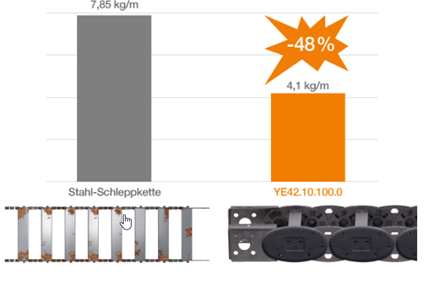

Saving weight plays a major role in many industrial applications. We have set ourselves the task of Tech up and Cost down with lightweight energy chains.

For a crane, for example, the entire structural framework must be designed for the loads that occur. Here the dead weight of a cable drum with approx. 4t (at 400 metres travel and 10kg/m additional load) has much greater effects than the much lower dead weight of a plastic chain. The heavier the energy supply system, the faster the energy efficiency of the crane decreases. Added to this is the weight of the drum, the steel structure and the drive technology.

In addition to the weight savings, the modularity and freedom from maintenance characterise the energy chain.

We find a similar example in all applications around the mobile lifting platform. For example, at Ruthmann, a lifting platform manufacturer, the TB290 vehicle has the world’s highest lorry platform on a 3.5t chassis at 29 metres. In this vehicle class, weight reduction is the most important issue, as the classification depends on it.

A separate driving licence is required for all vehicle types >3.5t, which makes it extremely difficult to rent these vehicles to end customers.

It is recommended not to use a steel chain and to use at least a hybrid chain, in order to achieve a weight saving as follows.

Further examples of weight reduction can be found on the following website. https://www.igus.eu/info/echains-techup-costdown-weight?L=en