Visualise condition monitoring system easily with the help of 3D data and schedule it at an early stage

Richard Habering | 7. February 2022

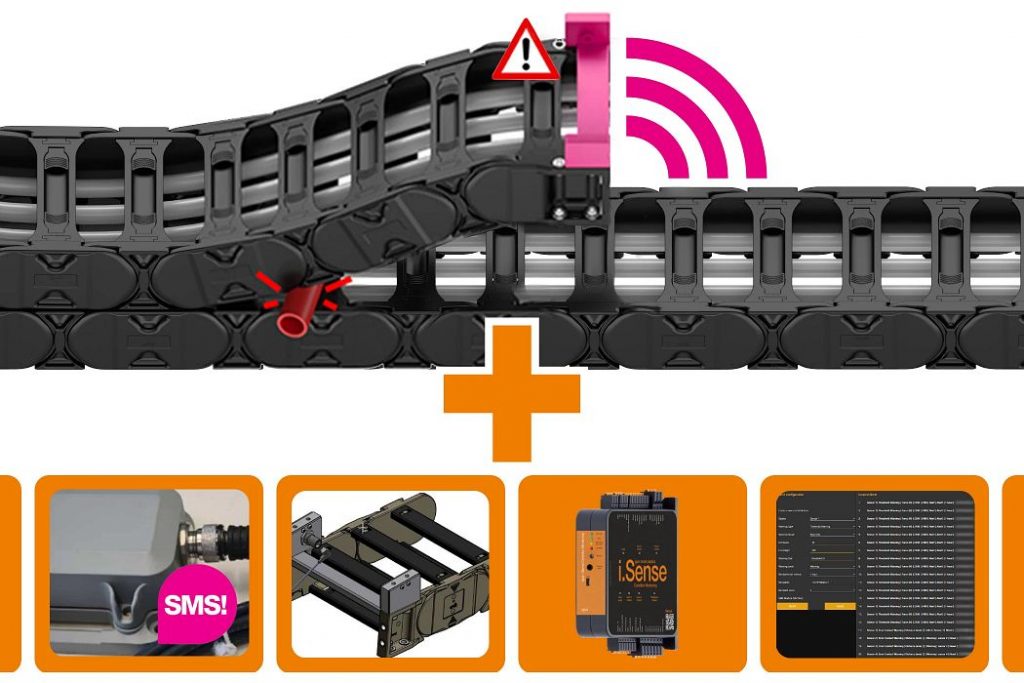

Condition monitoring systems are designed to eliminate unplanned downtime of machines and industrial plants by means of permanent condition monitoring. Continuous machine data acquisition and evaluation allow problems to be identified early on in fault management, fault analyses to be carried out and machine failure to be proactively prevented. Another advantage of condition monitoring systems is the fact that they are often the technical basis for modern maintenance strategies such as preventive maintenance or predictive maintenance.

When and how to integrate the condition monitoring system best into the design process?

But where do they start in the design process? In most cases, the individual components such as the necessary sensor technology for plant monitoring or the software for evaluating the sensor data are available from a wide variety of manufacturers or suppliers. Only a few large suppliers already offer integrated complete systems. Therefore, it is even more important to get to know the physical components at an early stage as well as to plan their integration into one’s own design. Besides the beautiful glossy images from marketing and sales, special 3D visualisations are best suited for this purpose.

With these so-called “Govies” the user can understand even complex or hidden applications and functions by moving through the product independently or with the help of the playback function. Full information about the condition monitoring systems from igus – called i.Sense – can thus be obtained online. Further information such as assembly instructions or manuals can also be found here in the help section.

Intelligent sensor technology for “touching” with the freely accessible 3D data

In the next step, the design data of the respective condition monitoring sensors can then be freely downloaded at any time from the igus 3D platform and implemented in the company’s own design software. Pretty much all common 3D exchange formats like STEP, DWG, or many more are available. In addition to the pure sensor technology for machine data acquisition, data evaluation and visualisation naturally also play a major role, which is why all the status information of a demonstration machine can be viewed here in this online dashboard at the igus trade show in Cologne.

Ready-to-install condition monitoring system in just a few clicks

To make the path to an intelligent condition monitoring system even easier, we have put together ready-to-install condition monitoring systems in the online shop. These predefined complete sets enable you to obtain a fully configured assembly to match your existing energy supply system in just three clicks. There, too, the concrete 3D files can be downloaded once again. This means that you are always in a position to equip your energy supply system with intelligent sensors at the next maintenance appointment without a long lead time.