Underwater cables

Jan Arnoldy | 24. April 2020

Cables are used in many areas. Some cables must meet very special requirements or withstand certain external factors. Consider cables that are used under water.

What problems arise for cables used in underwater applications? What solution approaches are there?

Longitudinal and transverse waterproofness

There are a number of things that cables that are used under water must be able to do. Under water, pressure increases with depth. This can be illustrated with the experience of a diver who feels the pressure building in his ears as he goes deeper. When cables are used underwater, they are subjected to this pressure. The most important condition, then, is that the cables used be able to withstand the prevailing pressure.

That is why such underwater applications require cables with a waterproof outer jacket. The normally extruded jacket material such as PVC, PUR, and TPE slowly takes on water because of the prevailing pressure. This causes it not only to swell, but also to become softer. There is therefore no longer any guarantee that the cable is sufficiently protected. The result is that water slowly penetrates into the cable’s interior. In the worst case, if the cable’s insulation is also damaged, short circuiting and failure of the entire system could result.

This ingress of moisture through a cable’s outer jacket is called transverse ingress.

When transverse ingress occurs, moisture spreads in the longitudinal direction within the cable. This is called the capillary effect. The liquid is continually pressed further through the small gaps and cavities in the cable.

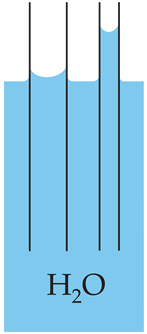

The capillary effect can be easily illustrated with a glass of water:

If you put a drinking straw into a glass of water, you will see that the water level is higher in the straw than in the glass.

To avoid this, we need so-called longitudinal waterproofness. To achieve it, swelling substances such as swelling non-woven fabric is inserted under the outer jacket. These substances swell upon contact with water, preventing moisture from spreading inside the cable.

Jacket materials for underwater applications

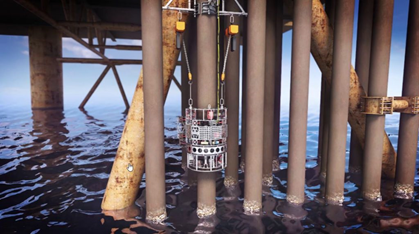

Underwater cable use requires materials that are permanently sealed. A cable’s outer jacket can be sealed by such means as using a rubber mixture. The swelling substances mentioned above are also used under the jacket.

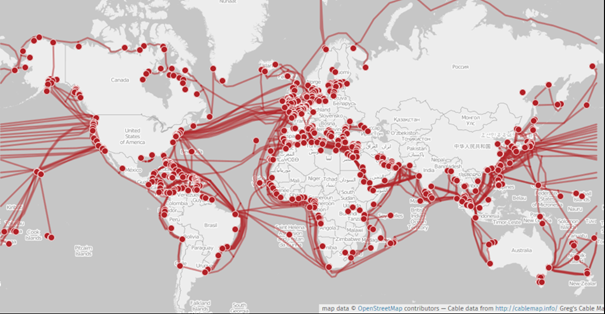

This type of cable is used in a worldwide network of cables, thus contributing to networking the entire world.

Conclusion

We at igus have specialised in cables for moving applications. Our chainflex cables are therefore only suitable for applications with low or periodic water influence and not for continuous use deep under water.

The reason for this, is that we must ensure the materials’ abrasion resistance, and we cannot do this with rubber-like outer jackets.

To put it simply,

if the energy chain is located a few metres under water and resurfaces occasionally, it can have a PUR or TPE outer jacket.

We are always interested in identifying solutions. Do you have an application that we could assist you with? Contact us, and we would be happy to work with you to develop a solution.