This is how you seal plain bearings reliably against the ingress of dirt

Lars Butenschön | 16. April 2020

Most plain bearing manufacturers – and igus® is no exception – advertise their bearings with the attribute “insensitive to dirt”. But what does that actually mean? And what do you do when you have exhausted the limits of this rather subjectively formulated concept? In equipment intended for really rough environments, such as mining, earthworks on building sites or in agriculture, plain bearings that are “insensitive to dirt” reach their limits sooner rather than later. The classic method in these cases is to seal the plain bearings with grease, which is permanently pressed “outwards” and counteracts the penetration of dirt. But this is neither particularly good for the environment (where the lubrication inevitably ends up), nor cost-effective. Due to a central lubrication system, supply lines, lubrication grooves and various other aspects, this type of protection against corrosion and dirt is complex and expensive.

In the search for a solution to this problem, we have found an amazingly simple solution. But let’s first get an overview of what alternatives are available to seal plain bearings against dirt ingress.

Very simple (or is it?): Sealing with O rings

Although O rings made of rubber are cost-effective and available in many variants, and if used correctly, they provide excellent sealing … they can only be effective if the tolerances of the plain bearing, housing and shaft are very precisely matched to the requirements of the sealing ring. In addition, the shape of the bearing position must be designed in such a way that the O ring is held in the bearing position as firmly as possible.

Lip seals

Another frequently encountered and cost-effective exponent of seals for plain bearings. Due to their design, these seals provide a sealing between shaft and bearing and also only when the diameter tolerance of the seal is exactly matched to that of the shaft. Rather difficult in the world of the more roughly tolerated components of commercial vehicles, construction machinery and soil processing equipment. However, the main disadvantage is the lack of sealing in the “axial direction” and the insufficient protection between plain bearing and housing.

Already old hat for some – felt seals

Felt seals are not a new invention. They are used in some areas of drive technology, but are also found in some pillow blocks as accessories. They were also used in older vehicles in the past, so you can still find them in vintage cars today. They are also found as problem solvers in some agricultural equipment.

The advantage: felt can be strongly compressed without much resistance, but protects against dirt and dust in any case. Therefore, it literally “nestles” itself against the adjoining components. And that even with coarser tolerances. Since the felt offers little resistance during compression, dirt that gets between the felt and adjacent moving parts is not pressed down hard and can therefore hardly cause any damage. The felt gradually becomes clogged with dirt during operation and finally forms an impenetrable barrier for further dirt.

And for dry-operating plain bearings made of polymer, felt has another advantage: the wax required for corrosion protection or to reduce friction in the running-in phase, depending on the shaft material, is held securely in the bearing position by the felt. So this “initial lubrication” is only necessary once and the bearing remains completely maintenance-free regardless of some lubrication. There is no need for relubrication.

Added to this is a low coefficient of friction of 0.22 in dry operation against steel, for example, and good temperature resistance.

Are you searching for solutions to seal your plain bearings? Please contact us!

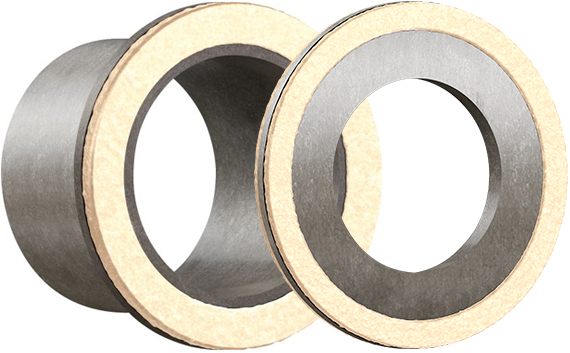

With the new iglidur® SG03 plain bearing, we have combined the advantages of felt seals with those of dry-operating polymer plain bearings made of our proven iglidur® materials in one component. Choose from catalogue dimensions in the form of thrust washer or bushing, or design individual special solutions with our support.