The right plastic for plain bearings: it all comes down to this

Lars Butenschön | 11. December 2020

If you are reading this blog post, you have probably already found out that there is no such thing as “the plastic” for plain bearings. Plastic plain bearings are available in many different plastics. Many of them with more or less exciting sounding brand names. Others with even less memorable abbreviations or codes. Can it be a POM? Or a POM-C? Maybe a something-with-glide instead? Or would you prefer a PA6630GF10? It is not uncommon to find out prices only after a proper request-and-offer procedure, and even then the comparison is not necessarily easier. Marketing descriptions trump each other with sizes that are technically almost impossible to classify. Very good wear properties or excellent sliding properties, high mechanical resistance and good flexural strength; the possibilities seem endless. The supposed way out: data sheets. But what does the maximum moisture absorption or the elastic modulus say about the specifications as a plain bearing? Even a high-temperature, high-performance polymer can squeak or unintentionally abrade aluminium shafts. In this article you will learn what really matters when choosing the right plastic for plain bearings.

What should it be capable of?

It doesn’t matter whether you’re buying a TV at the electrical shop round the corner, a pair of running shoes or a car. Any reasonably qualified sales consultant will ask you exactly that. “What exactly is your plan?” (Of course, in variations). And there is no sales pitch behind it at first. It is (or should be) a matter of finding out what is important to you. And which product features are not needed at all or are even a hindrance. After all, the more specialised a product is to meet certain requirements, the less it meets certain other requirements. My family van is good at carting an endless amount of stuff through the countryside, but not particularly good at driving on the left-hand side of a 3-lane motorway. Or in low-emission driving.

The point is: try to define as precisely as possible what you intend to do with the plain bearing. Important criteria are:

- The load acting on the bearing

- The type, speed and frequency of the movement taking place

- The ambient temperatures

- The installation situation (What exactly is to be stored. And where?)

- Further environmental influences such as wetness, chemicals or weathering

All these factors determine which plain bearing you need. The combination of load, movement and ambient temperatures is above all decisive for the friction-related heat that is later generated in the bearing position. This is expressed and compared using the so-called pv value. Here you can already make an initial statement about the suitability of a material for your application.

High temperatures above 80°C require special, temperature-resistant materials. In addition, these temperatures in operation naturally influence the pv value mentioned above.

Other environmental influences, such as wetness or chemicals, may in turn require materials with high chemical resistance.

In case of doubt: “the standard”

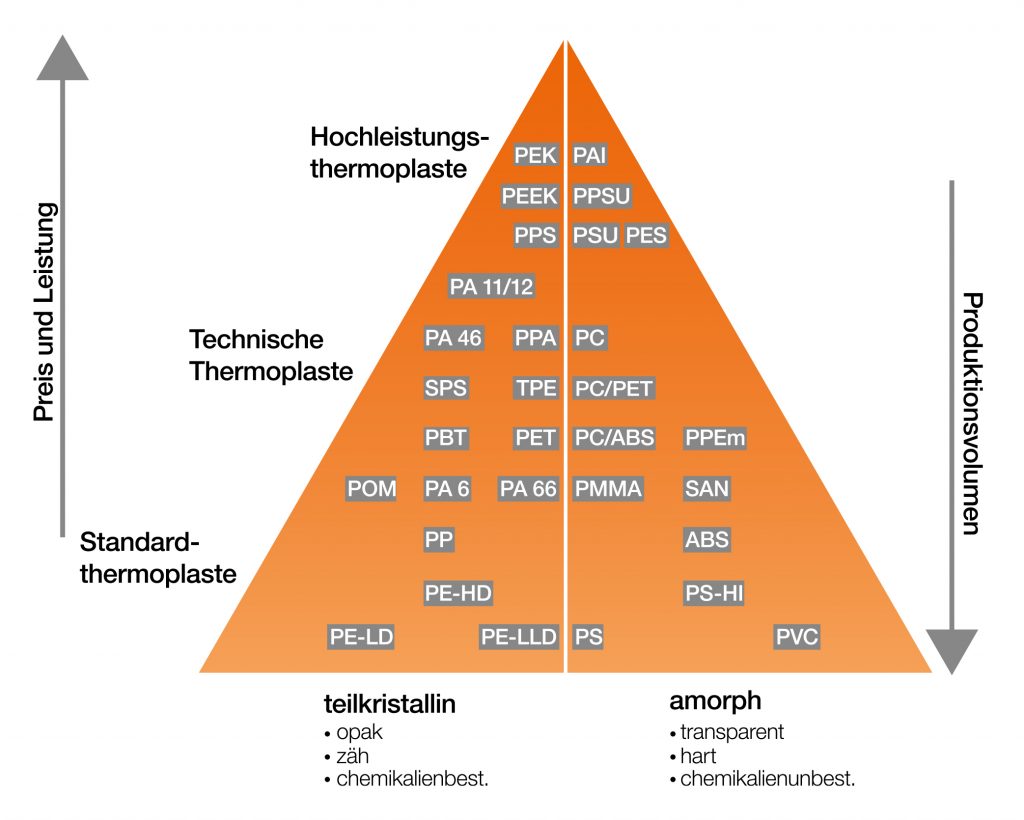

Just as there are televisions, cars or shoes that somehow, but not perfectly, fit most life situations and are therefore easy on the wallet, there are also plastics for plain bearings that can do a little of everything but nothing outstanding and cost comparatively little. These include the fairly common and readily available “standard” construction plastics such as POM or PA66. For applications with rather low speeds and loads (to put a technical and concrete figure on it: below approx. 0.5m/s in rather sporadic operation and with loads below 1-2 MPa) these are already sufficient. Nevertheless, it makes sense to use options that are additionally “tribologically optimised”, i.e. improved with solid lubricants such as PTFE or MoS2. In the case of plain bearing plastics that are sold without the name of the base polymer (e.g. PA66 or POM), it helps to look for indications such as “standard” or “base”. The “starter options” often consist of the base polymers mentioned.

But the more special the requirements – which can include a more exotic shaft material or even higher operating speeds – the more complicated the choice of the right plastic becomes.

We will find the right plastic for your plain bearings!

igus GmbH has been developing and producing polymer plain bearings since 1964. The mission: to develop plain bearing polymers whose service life can be precisely calculated in advance. (Find out how to do this here). With our free expert tools, you can determine the most cost-effective and best-suited polymer for your plain bearings in no time at all. Alternatively, our “real” experts will advise you and work with you to determine the requirements of your application and the appropriate solution. Everything from a single source and no minimum order quantity.