The right plain bearings for cleaning at high temperatures

Jan Michels | 27. March 2020

Many different machines are used in the packaging, food, and beverage industries. There is one thing that most of the different machine types have in common though: they are regularly and intensively cleaned. And they are cleaned at temperatures often above 100°C.

igus offers several polymer plain bearings that have no problem at these high temperatures. iglidur H, H1 and H370 can be used at temperatures of up to 200°C (up to 240°C for short periods). iglidur X, X6 und Z can be used at temperatures of up to 250°C (up to 310°C for short periods). But caution is advised: if there is contact with steam, iglidur Z should not be used; instead, use X or X6.

If temperature resistance is necessary and there will be direct food contact, iglidur A350 (up to 180°C) or A500 (up to 250°C) is the right choice.

Cleaning at higher temperatures may cause plain bearings to “wander” out of their housing holes. The bearing’s press-fit seating is then lost.

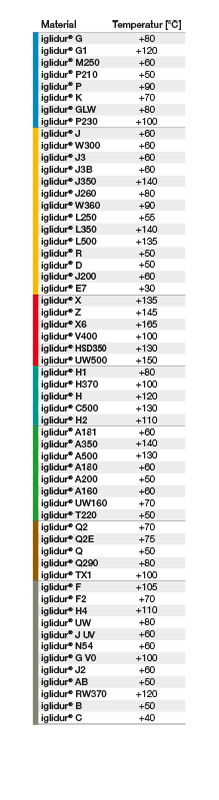

How can this be prevented? Constructive measures (such as using a flanged bearing) or a different material are recommended. We include an overview of the temperatures at which each bearing material must be secured.

More information about food-grade materials can be found here (in German):