The components of the igus:bike in the test laboratory – tested and safe

igu-blog-adm | 25. January 2023

For igus, safety comes first. For this reason, when we bring new products onto the market, they are tested beforehand. And for a really long time, over and over again. And then optimised. And tested again. And this goes on until we are satisfied with the service life. Which then lies beyond any norm. For this purpose, igus® has had its own test laboratory since 1985, which now occupies a floor area of 3,800m². And on a small part of it are the test rigs for the igus:bike. Because we only put the bike on the road when every single component meets our requirements and we know for sure how long they will last under real conditions. This is how we ensure that they are reliable and offer maximum security.

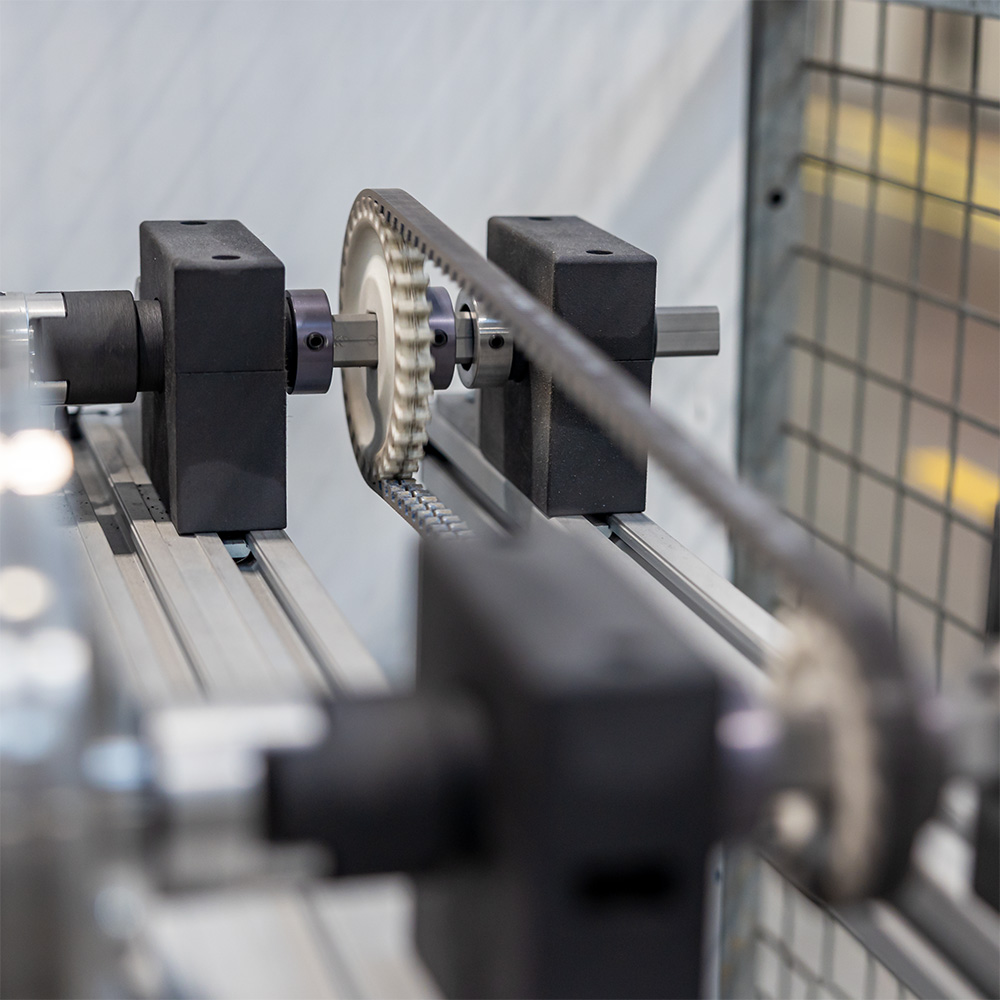

Thanks to our experience of over 35 years in building test rigs, the bicycle test laboratory takes up little space. The test rigs are compact and thoroughly test our motion plastics® components for the igus:bike. In our load tests, the components are loaded with increasing force in order to find out the maximum load capacity. If this does not meet our expectations, the design of the component would be improved. In the best case, when everything fits and it’s off to the endurance test rigs.

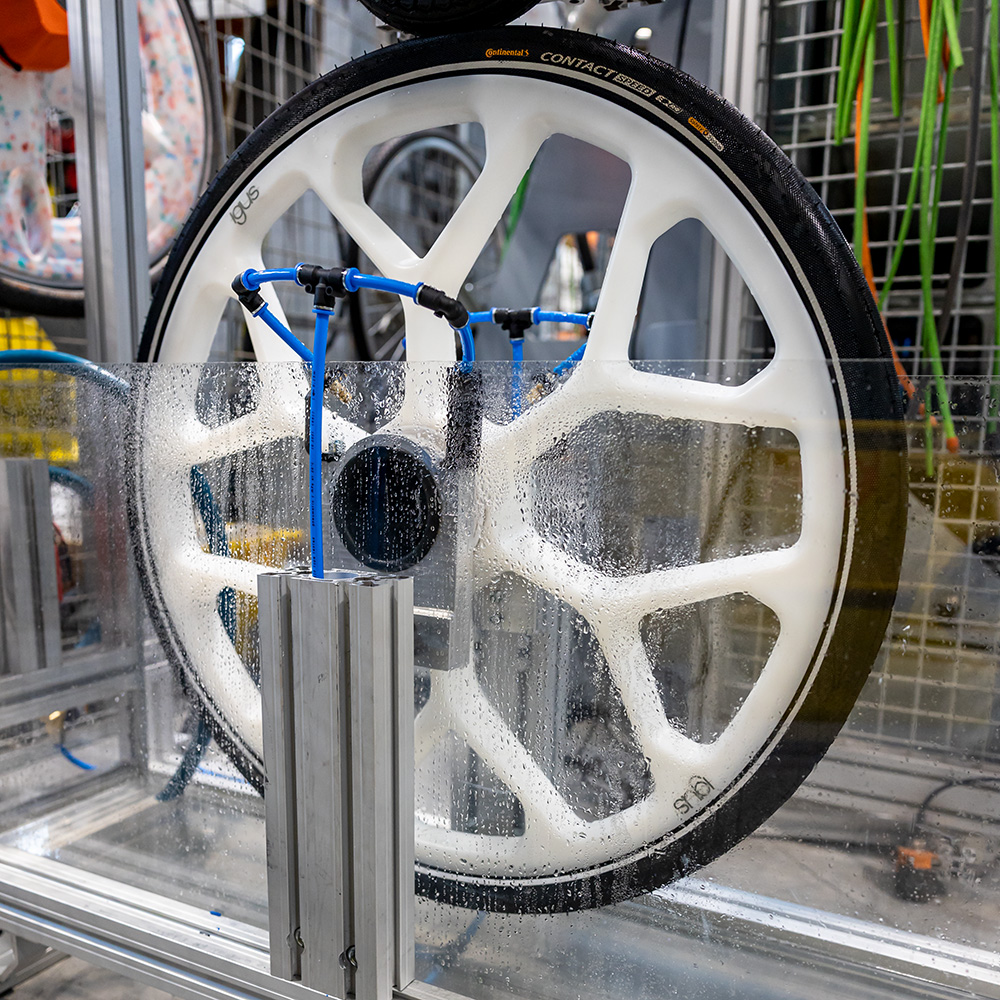

As the name suggests, the igus:bike components made of plastic are continuously tested here and the daily use of the bike is tested in a compressed amount of time. It rotates, pulls and pushes automatically to ensure that the bike can be used reliably and for long periods of time in everyday city life. In addition, environmental influences are simulated, for example by spraying water on the components.

There are currently 14 test rigs in the test laboratory, which are in lively use. More will follow in the near future. Something is moving everywhere, the most diverse sounds of the tests draw attention to themselves, fittings and monitors with moving pointers and numbers vie with each other. The wheels rotate at 25km/h, are additionally loaded from above and receive impacts from below to simulate uneven ground. In addition to the wheels, the ball bearings are of course also tested here, both in dry and wet conditions.

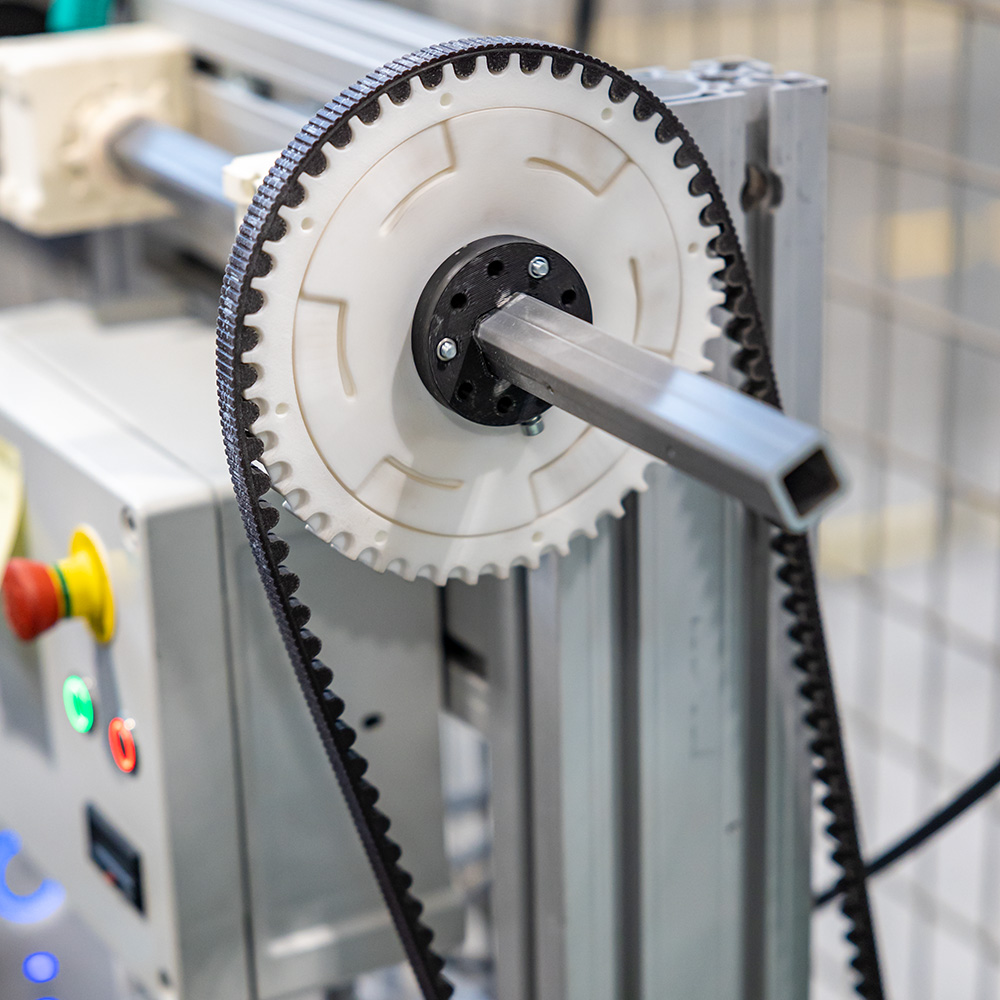

On another test rig, the freewheel rotates happily under load, on the next rig the same thing happens with the belt drive. Of course, there are also test rigs where the crank is subjected to extensive tests both alone and with a pedal. All test rigs are monitored so that in the event of material fatigue it can be seen immediately how long the respective component lasted. This is how we ensure that the riders of the igus:bike can always be on the road safely and that the plastic bike is virtually maintenance-free.

Are you interested in all developers of the igus:bike? Then please click here.

Would you like to follow the igus:bike project even more closely and never miss the latest developments, photos and stories? Then follow the igus:bike on Instagram or Facebook!

More information about the bike and the project can be found on the igus:bike website.

Or would you like to pre-order the bike with its unmistakable design without any obligation? Then this is the right place for you!