The chainflex cables can be bent kinked!

What is the bending factor?

igu-blog-adm | 7. September 2021

It is likely that everyone has taken a spoon from the kitchen at one time or another and started bending it. The first time I bent a spoon, I looked confused when I couldn’t bend it back the right way. So I did the only “logical” thing for a little boy and made sure my mother would never find that deformed spoon again. When I started at igus, I was confronted with bending again. This time, however, it was with cables and not with spoons! Let’s take a closer look at what the bending factor is all about today.

In the early days, I kept hearing terms like minimum bend radius or bending factor and trying to understand and classify them. In this blog post we would like to explain what exactly the bending factor is, how it relates to the minimum bend radius and why it plays a special role in certain applications.

From the cable to the bending factor

Based on a DIN test, the cable manufacturer usually specifies the bending factor for fixed installation and occasional movement. Fixed installation means that the cable is bent once and installed in the same way as, for example, cables for sockets in the domestic installation. These cables usually consist of a rigid, solid conductor and are difficult to bend. Occasional movement involves consuming devices that are, who would have thought it, sporadically moved. There are other examples in the kitchen, such the dishwasher or a stand mixer. These cables have cores with stranded wires that are twisted together and are much more flexible.

Since igus specialises in the use of cables in the energy chain, chainflex cables also receive a bend factor for the energy chain. The energy chain is the most demanding application for a cable and therefore the bending factor is highest here. A spoon might bend a few times before it softens or even breaks. To avoid this, chainflex cables have been optimised for use in the energy chain and can be bent up to several million times.

In accordance with our chainflex guarantee, the recommended bending factor is stated for a specific temperature and travel range. As a result, it can vary, even with the same cable. Further information on the chainflex guarantee can be found here.

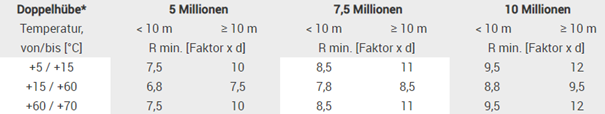

Diagram 1: Temperature and travel-based bending factors (R min.) using the example of the CF6 cable series. Installation of the cable is recommended within the medium temperature range.

Why is the bending factor so important?

Fortunately, cables do not behave like spoons and can be easily returned to their original position. Nevertheless, due to the continuous movement and bending of the energy chain, the installed cables are continuously stressed. The inside is compressed and the outside is stretched. An incorrect bending factor will cause damage to the cable. This may cause a cable failure. Therefore, one of the most important factors for the durability and operational reliability of a cable is the selection of the correct bend radius.

The bending factor can be used to calculate the minimum bend radius of a cable. The formula for this is:

Minimum bend radius = bending factor x d

Where “d” is the maximum outer diameter [in mm] of the selected cable.

The appropriate cable should not be bent below the calculated value, so that the functionality is guaranteed in the long term. The larger the bend radius actually used compared to the calculated minimum bend radius, the longer the expected service life of the cable.

The right cable for your application

In addition to aspects such as travel, temperature or oil resistance, the bend radius and the bending factor is an essential element for selecting the right cable. This criterion is particularly important for narrow installation spaces. The company igus® has cables in its product portfolio with a bending factor between 4 and 15. On the one hand, this technical diversity allows you to select the cable with the appropriate bend radius and to design even the tightest installation spaces without any problems. On the other hand, there are also price differences. As a rule, cables with a higher bending factor are cheaper, so you can save costs by choosing the correct cable.

For more information on saving money and/or improving technology, visit our price check page.

Conclusion

Using a potentially more cheaper cable with a high bending factor can break and become a costly over a longer period of time. Namely, when machine breakdowns occur and maintenance measures become necessary. So that no one has to foot the bill for it, it should not come to this in the first place and the correct cable should be used right from the start.

Are you unsure which cable or which bend radius is right for your application? Don’t let us spoil your soup, but talk to us! We will be happy to help you.