Stripping cables – who wants to do that?

igu-blog-adm | 19. November 2020

I don’t know any electrician who enjoys stripping cables.

Stripping is no fun on a workbench. At a machine, the lack of space and poor lighting often presents us with completely different challenges and also involves a risk of injury. In a control cabinet between terminal blocks and other components, it is just not possible to work well.

Stripping cables is a necessary evil. Just as unpopular as sweeping the workshop or cleaning up assembly vehicles. Once you have completed the stripping of the cable, you will often find that the core insulation is damaged. You start all over again, or even worse: you try to make costly repairs, because otherwise the cable is too short.

The right dissection tool

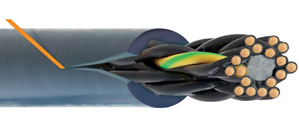

There are excellent tools for standardised cables such as NYM or NYY. For example, those of the JOKARI company. They can be used to safely strip cables without damaging the cores. For such tools to work, the cable must be manufactured symmetrically so that a round cut is conceivable. The cores all lie at the same depth in the cable.

This is not a problem with standard cables, but it is excluded for special cables of different manufacturers. High-quality cables are usually constructed in such a way that the jacket sits extra tight on the stranding or the shield. In this way the cores are well guided in the application. This makes the cable strong and robust. This also speaks against quick and easy removal of the jacket. So the choice remains between high-quality cable or easily strippable cable.

The idea – removing cables with a tear strip

For this reason, a few years ago we incorporated a thread into the outer jacket to make it easier to strip cables. I was inspired by the little red film strip in food packaging.

How nice and practical it is to have access to the contents. And that without damaging the contents and packaging. There should be something like that for cables! With that the idea was born. But the road to the finished product was long. Many questions arose: What material should the thread have? What colour should it be? How is it inserted into the cable? Does this affect any standards? How can you grip the thread? Mountains of question marks …

Back then, we simply started to look for threads that might fit. Then our development manager and I opened cables with a longitudinal cut, removed the stranded structure and placed the thread on top. Finally we put the previously stripped jacket back around it and subsequently opened the jacket again with the thread. It had something of tinkering about it.

It had to be a thread! A simple wire – like a drain wire – does not work. With this knowledge we approached manufacturers of threads and asked for their experience of this. No such luck! For there was no experience. No one had ever done this before.

We then ventured into initial tests with a manufacturer whose products we use in the fibre optic cable. Here we discovered a thread that cuts the jacket well, does not tear and yet does not damage the cores in movement. This was followed by countless other tests and trials to achieve safety. Today we use this tear strip, the so-called CFRIP, for our standard cables. Almost every cable with a PVC or TPE jacket today has a CFRIP thread in the inner or outer jacket.

The CFRIP tool

The advantage of the tear strip in cables is that it is also easier to strip long lengths. The cores are not damaged, nor are the hands, and a time saving of 50% is achieved.

This result was not enough for us at that time, because the thread was difficult to grip. We needed a way to get a better grip on the thread. The actual thread is very thin and delicate. It can be torn off with pointed pliers and cannot be held properly with the fingers. A solution had to be found and it should be cost-effective.

Therefore, in addition to the tear strip, we developed a small tool to grip the thread firmly and open the cable without damage. The CFRIP tool. With this small handle you can grip the thread and use it safely to open the jacket – almost like a zipper. By simply pulling the CFRIP tear strip, the cable is opened to the desired length in a controlled manner. The cores can then be conveniently removed from the jacket.

Now I have told you a lot. The best thing is to test it yourself. Send me an e-mail or call me and I will send you a suitable sample.