Spherical thrust bearing – 2 cost-effective alternatives

Lars Butenschön | 21. July 2020

The classic bearing position in the mechanical engineering textbook provides for a simple shaft in a ball or needle roller bearing that is mounted in a radial direction. But what if the bearing position must be supported axially? It is not uncommon for bolts or rods to be supported at the ends in an axial direction or to be supported so that they can move in a vertical position. The catalogues of various bearing manufacturers provide spherical thrust bearings for this purpose. These thrust bearings are in turn available in a wide range of variations. From thrust bearings to needle bearings. These solutions have the same pitfalls as their “radial” counterparts. They consist of many individual parts, require permanent lubrication and often cannot tolerate dirt or moisture. There are cost-effective alternatives that are often just as suitable. Here I will show you some of them:

The thrust washer as a spherical thrust bearing. Why complicate things when they can be simple?

The simplest solution is often the best. Instead of a complex component with various moving and wearing parts, why not choose one that has no moving parts at all and requires no additional lubrication or other maintenance? Often a simple thrust washer made of polymer does the job. In general, polymers are, of course, in many respects not as resistant as metallic parts of the same shape. But they don’t have to be.

The mechanical strength values of steels are by no means always fully utilised in ball and roller bearings. Added to this are the aforementioned disadvantages that these materials have. They must be permanently lubricated. Any unlubricated relative movement must be avoided. Polymers specifically optimised for coefficient of friction and wear resistance, such as, for example, iglidur® (What is iglidur®? – Find out more here) demonstrate all their strengths here. In addition, the flexibility of the materials provides solutions for special requirements such as extreme temperatures and food safety.

The advantage is obvious. A simple washer used as a thrust bearing, consisting of a dry-operating and highly wear-resistant material. Just install it once and you’re done. You can quickly and easily save not only costs in procurement, but also in the long-term maintenance and care of the machine. At the same time, you also save weight, which can increase the energy efficiency (or ergonomics, depending on the application) of the entire assembly.

The axial plain bearing – for unfavourable sliding combinations

One of the drawbacks of thrust washers is that, unlike axial ball or rolling bearings, the relative movement between the thrust washer and the shaft or moving components takes place. Irrespective of whether the wear takes place on the surface of the thrust washer as expected, this wear nevertheless depends heavily on the surface condition of the other friction partners. An example: plain bearing materials should always be selected so that they are softer than their counterparts. A fibreglass reinforced plain bearing material tends to grind “soft steels” smooth. It is therefore better to use a polymer that is as “soft” as possible. If, on the other hand, a counterpart with a relatively galvanised rough surface is moved against a soft polymer bearing, it rubs away the polymer quite quickly.

Sounds complicated, but in practice this happens less often. On the one hand, there are a variety of quite flexible plain bearing materials, on the other hand, there are appropriate aids available in case of need. For example with our iglidur® plain bearing calculator or with appropriate advice.

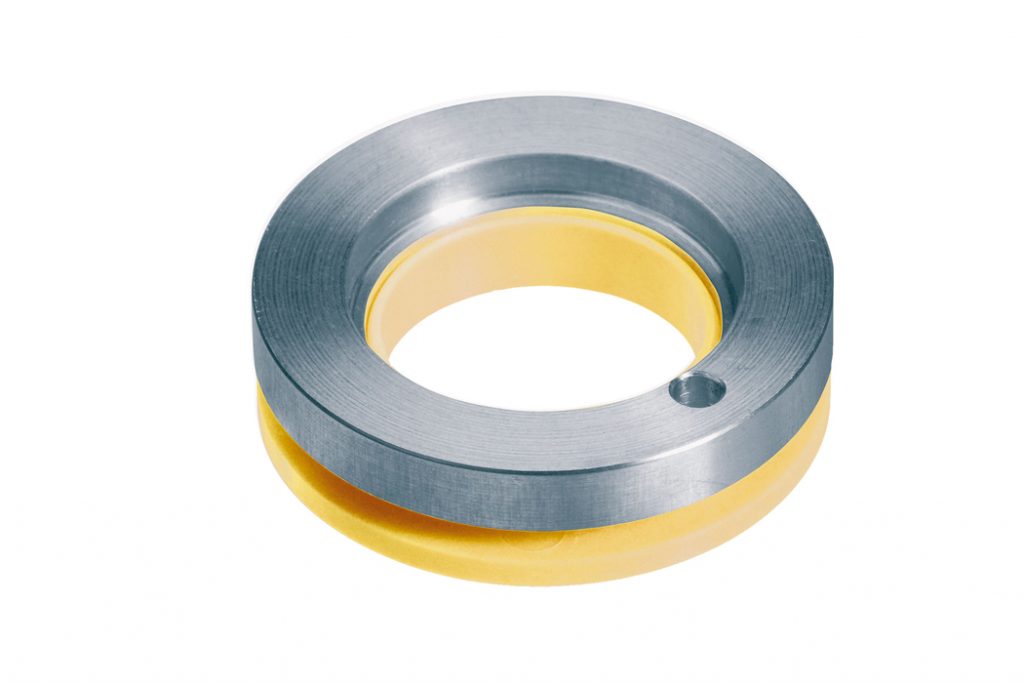

Another alternative are so-called axial plain bearings. (You will notice that the terms are beginning to sound a bit superfluous). iglidur® axial plain bearings consist of 2 rings, which together form a pre-tuned and optimised system of friction partners. This means that the relative movement only takes place within the component and no longer between shaft or housing and bearing. Here too, you can save costs and weight by eliminating the need for lubrication and maintenance, as well as the simpler design of the component.

Save up to 89% – We will start your plain bearing savings project

In the course of the standardisation and unification of parts list components, oversized components are often used. There is often great potential for savings through the use of more cost-effective or more efficient components. Our igus® application consultants will determine saving potentials together with you quickly and free of charge. The most cost-effective plain bearing – whether as a radial bearing or spherical thrust bearing – that is guaranteed to work. Online, by telephone or personally at your premises.