Skydrol – No problem for iglidur® materials

Florian Schiller | 4. June 2021

In aviation, as in the airport, the topic of fire protection plays an important role. This applies to all areas, including hydraulic fluids. In order to meet these strict requirements, the hydraulic fluid “Skydrol” was developed by Eastman.

It consists of a phosphate ester with different additives depending on the area of application, which prevent corrosion and erosion damage to valves, for example. Skydrol is coloured purple or blue to distinguish it from other liquids.

Skydrol LD-4, is the most widely used form and the gold standard at the airport. However, besides many very positive specifications, Skydrol is not compatible with many plastics, as they are softened and eventually destroyed. Therefore, special seals are used in the aircraft environment.

In order to prove the resistance of four selected iglidur® materials against Skydrol LD-4, we carried out some tests.

Test set up

Three test specimens made of iglidur® W360, iglidur® H, iglidur® X and iglidur® J respectively were stored in “Skydrol LD-4 (EASTMAN)”. Two test specimens each were placed in 100% concentrated medium for 1000 hours at room temperature. The customer drilled a hole in each of the test specimens so that they could be suspended in the separating layer between the medium and the air. Experience shows that the medium is most aggressive there. The removed test specimens were then analysed in the igus® laboratory.

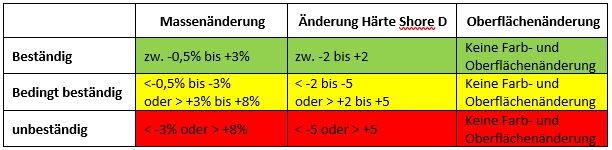

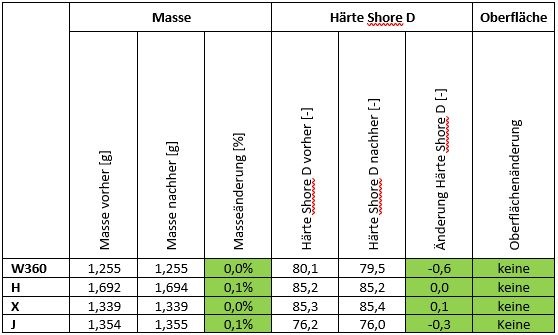

As analysis criteria, the mass and the Shore D hardness of the test specimens (see Table 2), as well as the colour, gloss and surface changes before and after the exposure were determined and evaluated according to the criteria from Table 1.

Results

The results in Table 2 show that the four tested materials remained within the limits of a resilient material in all categories. No change in the surface could be detected in the drilled test specimens either.

Based on the results of the measurements and the optical examinations, the resistance of the examined iglidur® materials to the used media is evaluated as follows:

- iglidur® W360 resistant to Skydrol LD4 (EASTMAN) (100%; RT; 1000 h):

- iglidur® H resistant to Skydrol LD4 (EASTMAN) (100%; RT; 1000 h):

- iglidur® X resistant to Skydrol LD4 (EASTMAN) (100%; RT; 1000 h):

- iglidur® J resistant to Skydrol LD4 (EASTMAN) (100%; RT; 1000 h):

The drilled test specimens show no visual evidence of chemical attack.