Scara solution: From the idea to the product. Episode 1

Marius Glaue | 21. July 2020

Status Quo CW29 2020

In this blog series we would like to show you how we develop a new product. The end of this series is still completely open at the time I write these lines or you read these lines.

Perhaps we will end up with no new product at all and fail halfway through. We´ll see. In any case you have the possibility to accompany me (us) on this journey. Here’s how it goes:

Where do we currently stand and why do we want to develop this product at all? Fortunately, many customers turn to us when they have problems with the energy supply system. In this case, an automobile manufacturer from Swabia contacted us as early as mid-2016. In the production line, around 40 Scara robots are in charge of various placements. The ball screw is directly connected to the rear stationary mounting. At that time it was an annual routine for the customer to check the connections and usually replace them due to wear.

The aim was to increase the service life of the energy supply system by at least factor 3.

What is the problem?

The main factors for the high wear is the operating speed of a Scara robot of up to 2,000mm/s in the horizontal plane in combination with 24/7 continuous operation. The feed of the ball screw as well as the rear stationary mounting must be mounted in a rotating manner to prevent torsion of the energy supply system. Furthermore, the inherent stability of the energy supply system was not sufficient, which meant that it was subject to very heavy wear above the fixing points. Therefore it was necessary to find a new corrugated hose and/or a reinforcement for it. Here, a good choice was e-rib, a product launched in 2015 that offers more stability for corrugated hoses of all kinds. The functionality of an e-rib can best be demonstrated in the following video.

Unfortunately, the e-rib does not have reinforcement at the two attachment points. The customer’s corrugated hose would have been more stable with the e-rib but, like the previous solution, would most likely have been too unstable above the attachment points.

Special customer solution

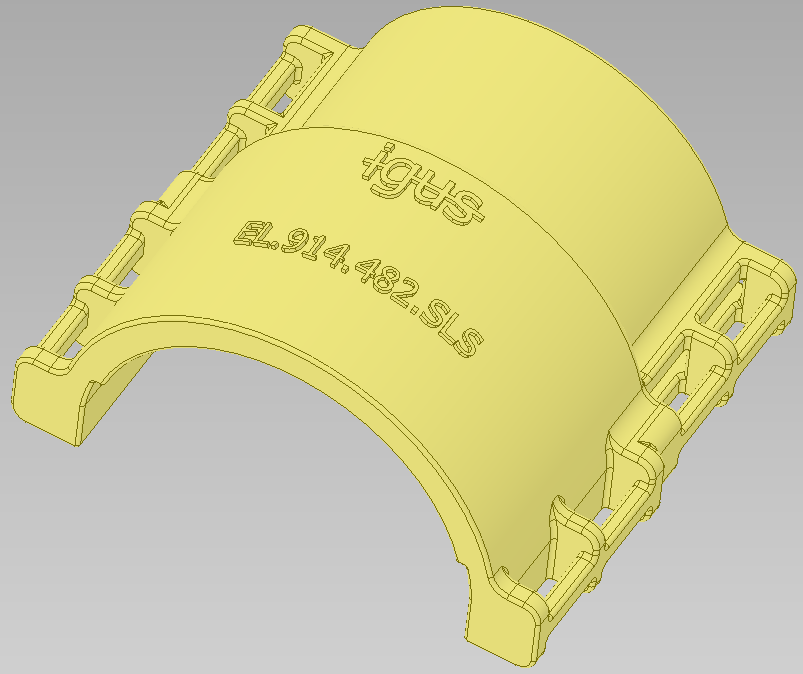

As already mentioned, in addition to a stronger attachment at both ends of the energy supply system, it must also be mounted in such a way that it can rotate at both ends. Here our customer has come up with his own solution, which has been providing excellent service to this day, 13th of July, 2020. Our focus was on strengthening the corrugated hose with the e-rib and reinforcing the connection points. On the one hand, the e-rib grips between the ribs of the corrugated hose and provides stability, and at the ends we provide the system with 2 supports (see following picture). The supports fit exactly on the ends of the e-rib and are mounted using cable tiewraps. They offer the corrugated hose + e-rib sufficient support and protection against buckling.

In combination with all 3 products (see following list) a special customer solution could be developed which has been in use since 2017 with about 6.8 million cycles per year without replacement.

- Modified e-rib

- End connection support

- Rotatable bearing

Inventory completed.

The proof that it works, in addition to exceeding all expectations in terms of service life and the increased requests from other customers for a similar solution, has encouraged us to develop a series solution. 3 weeks ago, with the friendly support of Epson Germany, we decided to develop a Scara solution. After a brief consultation Epson agreed to provide a Scara (G6-553S Manipulator RC620) for test purposes in Cologne.

If you now say: “Cool, but I don’t want to wait that long for the series product. I am building this solution myself.” “

Then you can already buy the required parts here, make enquiries and ask us for advice.

In episode 2 we report on the arrival of the Epson Scara robot and what to do before the first test begins.