Scara cable solution: From the idea to the product Episode 4

Marius Glaue | 28. August 2020

Crash already during warm-up

To stay with the comparison with motor sports, one can say that our suspension broke in the 1st lap. For those who haven’t seen the video from Scara cable solution blog Episode 3, here’s the link (go to the video) The video shows the first test metres, but unfortunately the whole thing only lasted a few minutes. The presumed weakness quickly became a certainty, because the 3D manufactured rotary connection did not withstand the loads. Unfortunately there is no picture or video material of the crash.

“Wipe your mouth and move on”

A different and stronger solution for the rotary connection was needed. After a short time we remembered the ball bearings of the P4.1 roller chain. As chance would have it, these ball bearings fitted into the rotary connection and we were able to install them the very next day. In the following picture you can see the press-fitted ball bearing.

Back on factual ground, but still with the same motivation as before. During the 2nd attempt we went to work with a little more respect for speeds and forces. We also decided to test the connection between ball screw and rear connection. In addition to the ball bearing, the shape of the front connection to the ball screw was also optimised. What previously consisted of three parts became one component. This change also minimises the number of parts in the system and later on simplifies the ordering process.

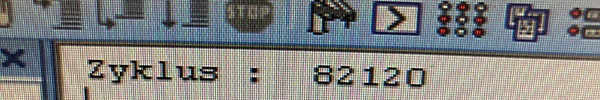

We let the application run during the initial days without filling to see if it was strong enough. Thanks to the robot’s high speed, we currently achieve 900 cycles per hour or around 20,000 cycles per day. After four days of continuous operation, the counter already showed 82,120 cycles.

The following video shows the setup we used for 80,000 cycles.

The degree of difficulty is increased

Since the Scara cable solution has mastered the 80,000 cycles without any problems after the changes mentioned, we are raising the bar a little higher. It was necessary to install the most realistic hose and cable selection possible. The CF9.02.12 was chosen for the cable, because it corresponds exactly to the assignment of the SUB-D connector on the robot. Additionally 2 x CAPE. A.04.0 (4mm Ø hose) and one CAPE. A.06.0 (6mm Ø hose) are used.

The goal is to reach the 500,000 cycles without complications. We would like to replace the P4.1 ball bearing with a xiros ball bearing.

We are curious how it will continue.