Returnable bottles and xiros®? What ball bearings can do in reverse vending machines

Patrick Czaja | 15. June 2021

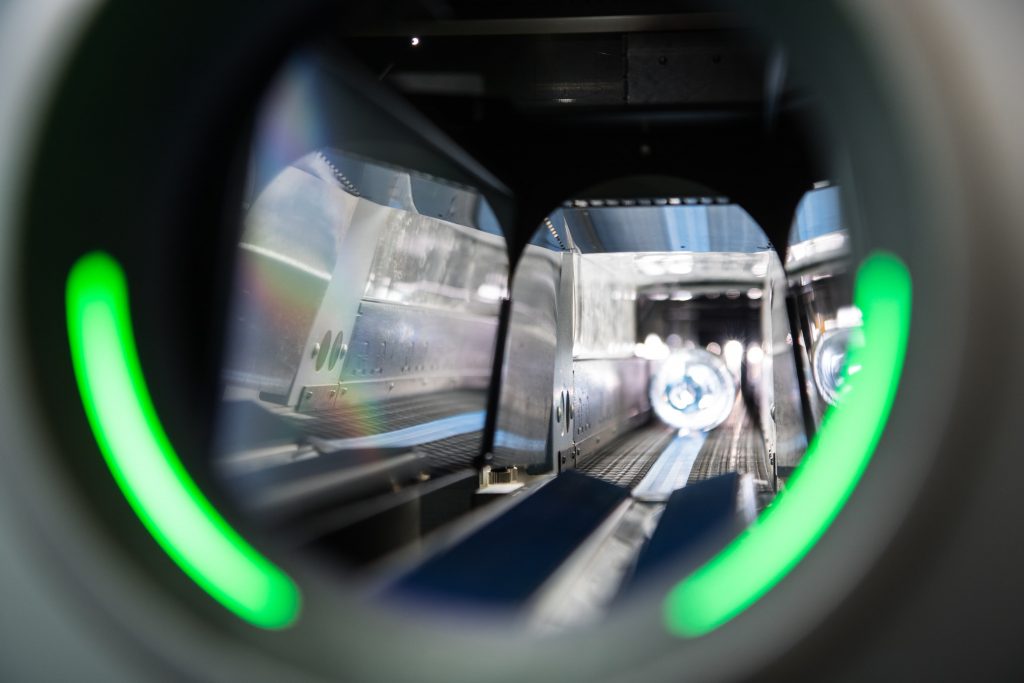

Every normal household in Germany has the problem: plastic bottles pile up and have to be taken to a nearby supermarket. With all the bottles in tow, you head straight to the reverse vending machine, get a receipt, and continue shopping. But close observation reveals a great deal of technology behind the reverse vending machine that someone familiar with it can identify. During supermarket opening hours, the reverse vending machine is in almost continuous operation. The components must be designed precisely for this challenge. Upon close examination, the conveyor belt is the component that attracts attention. The bottles are placed on the belt, the icon marking the bottle as returnable is automatically detected, and the bottles are sent to the shredder. But what do reverse vending machines have in common with our polymer xiros ball bearings? We will tell you.

Our focus now is on the reverse vending machine conveyor belts we just mentioned. They are in constant use and must be able to handle tough environments. One customer used metal ball bearings in a machined housing, which was very expensive for one thing and has a breakaway torque that is too high for another. Moreover, plain bearings were not a feasible solution either, since the breakaway torque was too high there as well and wear to the conveyor belt was faster because of the sliding effect. The solution the customer found was our xiros special parts. A mushroom-head design now ensures that the conveyor belt self-centres and runs extremely smoothly. The belt no longer slips over the bearings as it did in the past. Moreover, our special parts are 100% lubrication-free and are resistant to dirt.

Are you interested in our special solutions made of polymer? We would be happy to advise you, from idea to a cost-effective, customised solution. Find out more: https://www.igus.eu/info/special-parts-xiros