Prolonging the service life of energy supply systems on machines: 4 helpful tips

igu-blog-adm | 6. August 2020

The service life (also durability) of machines is the period of time in which the systems and machines are available in working order and can be used without replacement of components or machine failure. One of the most important machine components is the energy supply system. It is necessary to guide energy, data and signals safely from one place to another. From machine tools to crane systems. In the event of transmission errors or failure, individual machines or complete systems are no longer supplied with the required energy. This can affect the productivity and profits of a company. It is therefore important that the energy supply systems on machines last a long time.

You can find out more about how you can increase the service life of the energy supply system here

You can extend the service life of the cable carrier on machines as follows

Tip 1: Collect basic data of the application

Before you start looking for the right energy supply system, first collect all necessary application requirements. These include:

- Media connections (pipes and hoses)

- Application parameters (travel speed, acceleration)

- Type of movement (horizontal and vertical movement, circular movement, 3D movement etc.)

- Installation conditions

- Working temperature

- Environmental influences

Increase the service life of your energy supply system with an expert._x000D_

Get professional consultation in a simple and straightforward way

and receive a non-binding offer.

Determine now

Tip 2: Selection of the energy supply system

Energy supply systems can be found in various forms in industry: as an energy chain made of polymer or steel, motor cable drum, busbar system, cable carriage system (also festooning) etc. For a reliable and durable energy supply system, we recommend the use of polymer energy chains.

Polymer energy chains are modular, strong, cable-friendly, light, quiet and easy to maintain. As a rule, energy chains have a service life of 10 years or more. In our own test laboratory, energy chains are tested about 10 billion cycles per year under real conditions. We can therefore say exactly how long an energy chain can be in operation.

Find the right energy chain with service life prediction

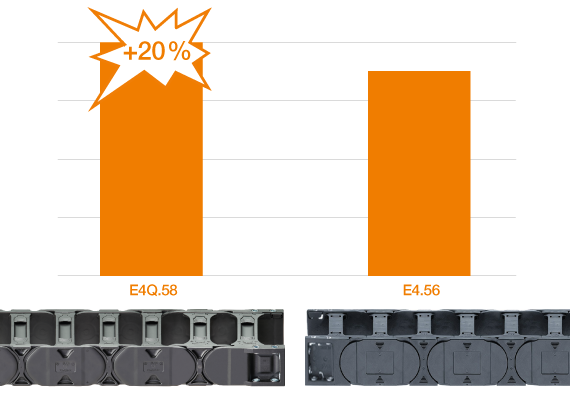

Example: 20% greater structural stability with the first-class E4Q

2 vertically and 2 horizontally arranged stop-dogs per chain link ensure greater rigidity for the E4Q, as a result of which longer unsupported lengths or heavier fill weights are possible. 20% stronger compared to the E4.1.

Tip 3: Installation rules for cables

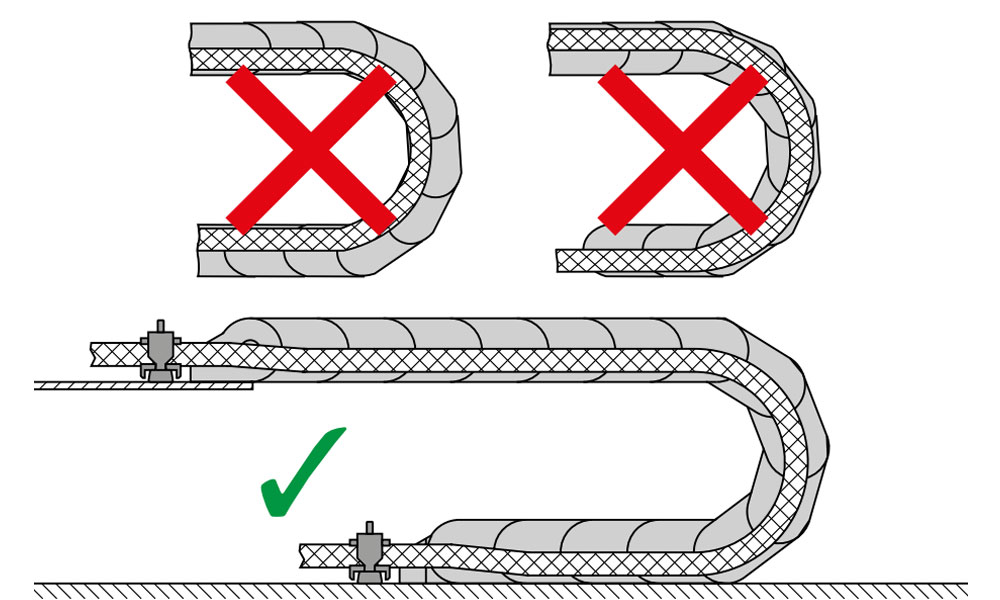

Cables supply the machine with energy and data. Protecting them is the task of the energy chain. With the correct installation of cables in energy chains, the maximum service life of the energy supply system is guaranteed. The following rules must be observed:

- Cables must be laid straight, without any twisting.

- The cables must be routed in such a way that each individual cable can move freely in the longitudinal direction.

- The cables must be able to move freely along the radius.

- If several cables with different diameters are used, use interior separations.

- Cables and hoses with different outer jacket materials must not be allowed to stick together.

- All cables must be strain-relieved at the fixed point and the moving end.

_x000D_

Tip 4: Use “predictive maintenance” early on

Through predictive maintenance, unplanned machine breakdowns can be avoided. With our systems for predictive maintenance integrated in energy chains and cables, it is possible to detect defects before they occur, avoid downtime, shorten repair times through early intervention and increase machine availability.

Increase the service life of your energy supply system with an expert._x000D_

Get professional consultation in a simple and straightforward way

and receive a non-binding offer.

Determine now

Practical example: Over 10 years without failure in operation

Still a world record held by igus: the longest polymer energy chain in the world with a 615m travel has been in use for more than 10 years, without failure, in the lignite power plant in the Czech Republic.