Plastic bearings for high loads? What does high load actually mean?

Lars Butenschön | 4. December 2018

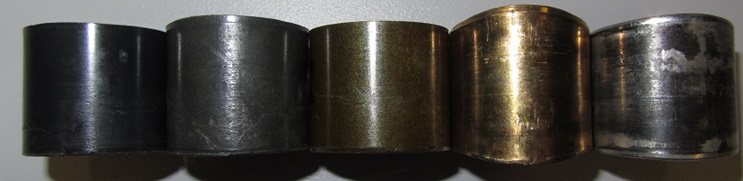

There is a saying among german conservative engineers going like this: “Wer Kunststoff kennt, nimmt Stahl”. “Those familiar with plastics use steel instead”. To be honest I didn’t hear this in quite a while now. But it´s still in the heads of many engineers. Even if they don´t know a word of german. In the year 2018 there is still scepticism about the capabilities of plastics. So let´s take a closer look on this. The saying is clearly aimed at the strength of the materials. And on paper, plastics are no match for steel or many other metals when it comes to high loads (with few special exceptions). And that’s also where the idea is born to prefer metal over plastics when it comes down to bearing materials.

The question is: Is it really as important for bearings? The answer – as you can probably tell already is “no”, but why?

Not everything labelled “high load” actually is

To let the cat out of the bag right at the beginning: You would think that “High loads” are actually quite easy to measure and be very comparable but in fact, “High loads” often are a very personal rating. It´s often surprising by how much the definitions of “High loads” differentiate in reality. There is the developer of mountain bike frames who calls the surface load of 60 MPa in the rear suspension bearings “High load”. Then there is the manufacturer of hydraulic lift tables who describes the load in the eyelet bearings of the hydraulic joints “high load” when they are really “only” 30 MPa. Odd. But people tend to judge things by comparing it to what they know and experience in their daily lives. So an engineer of mountain bikes might call a load of 60 MPa a lot while an engineer designing mechanisms for miniature pumps using mainly soft materials will rate 10 MPa as very high.

So what are “high loads”

The strain on bearings in particular and on mechanical components in general is determined by the applied pressure (or surface load for bearings). Without getting too technical here: This means the force applied to a certain area. A lot of force on a small area means high pressure. A lot of force on a big area means lower pressure. Or to give you a picture: The author of this text will sink in deep when going on snow with regular shoes. But with shoes looking like someone taped tennis bats underneath them – called snow shoes – he will be able to walk on the snow with ease. It´s this surface load or pressure that defines “high loads” if you compare it to the capabilities of materials. The load a material can take is usually described in it´s material datasheet.

The strain on bearings in particular and on mechanical components in general is determined by the applied pressure (or surface load for bearings). Without getting too technical here: This means the force applied to a certain area. A lot of force on a small area means high pressure. A lot of force on a big area means lower pressure. Or to give you a picture: The author of this text will sink in deep when going on snow with regular shoes. But with shoes looking like someone taped tennis bats underneath them – called snow shoes – he will be able to walk on the snow with ease. It´s this surface load or pressure that defines “high loads” if you compare it to the capabilities of materials. The load a material can take is usually described in it´s material datasheet.

So what exactly is “Surface load”?

Surface loads – and also pressure in general – is measured in “Pa” (Pascal). At least in the metric part of the world. Since in engineering and material science, the forces are usually quite high, you will go with “MPa” (Megapascal, 1000 Pascal). 1 MPa are equal to 1 Newton (N) per mm² surface. For the aforementioned man with the hydraulic cylinders and his 30 MPa that means the weight of 3 kilograms applied to 1 mm². Thats equivalent to a small hatchback car of 1200 kg carried by a Norm Index Finger tip of 20 x 20 mm…. Just to give you an idea how “much” 30 MPa is.

If you take this knowledge and apply it to the material data sheets of most plastics and metals used for making bearings, you will notice that most of them are actually fine for all the load scenarios I just described. Some plastics even go up to 100 or 150 MPa. Wow. Right?

But surface load isn’t all that matters.

If that would be the case, the article would end here. The german saying is correct, plastics are not stronger than metal so that’s why metal is the best bearing material. But as usual, the devil lies in the details. In general, mechanical components are designed by predetermined and calculated data for loads and strengths. But this is not as easy for moving parts. Components may end up being misaligned, loads don´t apply permanently and with the same amount. Instead they might increase or decrease rapidly. Lasting only as short as a few seconds or as long as several days on end. This not only makes calculating application parameters a pain, it also changes the requirements materials have to meet. The requirements shift from by-the-numbers comparisons of load resistance to other requirements. For example, a very hard material can be too brittle for alternating loads or even shock loads and vibrations. In these cases, a softer material, giving in before getting back to its original shape can be better suitable.

The wiser head gives in

Especially in scenarios with shock loads, vibrations and alternating loads, plastics can be better suited for high load applications in spite of metal may offer better abilities on paper. There is a number of applications out there like door hinges with swelling tilting loads that tore apart metal bearings and dirt paired with vibrations in tillage equipment in agriculture eat steel bearings lined with PTFE for breakfast. “Softer” and more elastic plastic compounds proved to be the superior solutions time and time again.

This is why it´s always worth taking a closer look at application data, comparing it with datasheets of different materials and – ideally – test under real life conditions.