Often underestimated and ignored. How industrial noise can be reduced by igus® products

Marius Glaue | 26. August 2020

Around one million people in Europe suffer from industrial noise – not just annoying, but a health hazard. Here you can find out what you can do to at least reduce the noise level of an e-chain. After all, one aspect of igus product development is to make the e-chains quieter.

Alongside cars, airplanes and trains, industry is one of the biggest sources of noise – from steelworks, chemical plants, power stations and ports, among others. We would like to do our part and, for example, make energy chains as quiet as possible.

Faster & even quieter P4.1

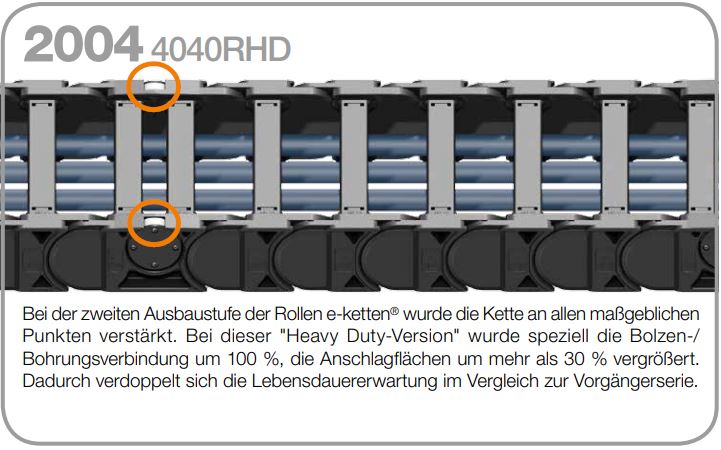

P4.1 energy chains are used in outdoor crane systems in ports. Even if you think, at first, that the noise level in the port is not important, it is essential to reduce noise emissions along with pollutant emissions. In roller chains of type 4040RHD (R = Roller HD = Heavy Duty) or 5050RHD the rollers run on top of each other and are therefore acoustically perceptible.

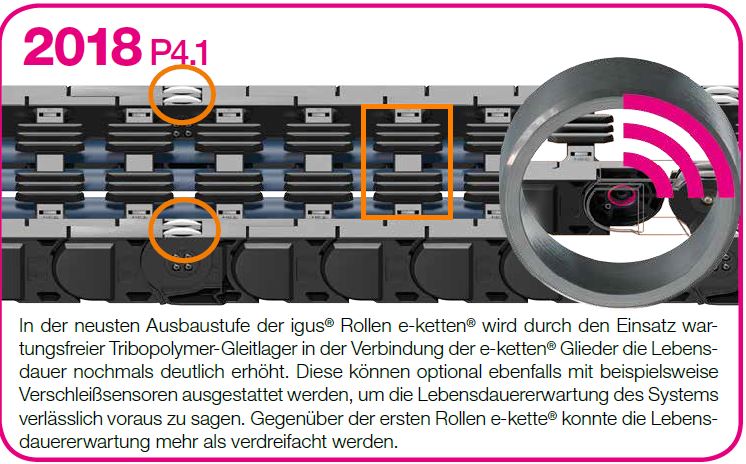

This is different for the P4.1 rol e-chain®, because here the rollers do not run on top of each other but pass each other due to an offset. . In addition, the P4.1 does not have wide rollers but two narrow split rollers on each side, which makes it possible to pass each other. (also see the following video)

This lateral offset of chain and guide trough eliminates the noise when two roller chain links meet. This required offset is ensured by a deliberate vertical bend in the aluminium trough. In addition, sliding guide elements on the crossbars in the inner radius of the chain ensure constant guidance of the e-chain (see orange box in the upper picture). This design has enabled us to significantly reduce the noise emission of the energy chain. Laboratory tests have proven that the P4.1 e-chain produces a noise level of only 76dB at a speed of 4m/s. “

The P4 e-chain is one of the heavyweights in the igus range – it allows additional loads of up to 30kg/m.

Even the little ones can be quiet

Laboratory tests show that smaller e-chains, which are used in machines, plants and vending machines, move even more quietly. The noise levels are between 33dB and 46dB, confirmed by expert appraisals by the accredited certification body TÜV Rheinland. The E6.1 series achieves a noise pressure level of only 37dB. For comparison: a room fan is about 35dB loud, the twittering of birds about 50dB. Again, there are some design tricks behind the low values, which are simple but effective.

The innovative E2.1 brake design

Compared to the E2/000 series, the E2.1 chain series uses an innovative brake design for the first time. (see next photo). This technology is not visible from the outside. Small, springy wings can be seen opposite the stop-dog pockets on a disassembled chain link of the E2.1 series. (yellow marking). These ensure that the next chain link is gently braked or cushioned when it comes into contact with it.

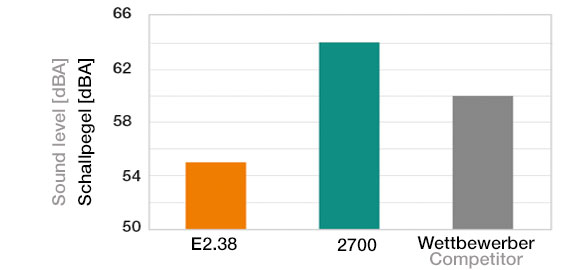

This braking function also significantly reduces the noise volume of the e-chain in its movement. The following graph shows that the noise emission of the E2.38 (part of the E2.1 series) is significantly quieter than 2700 (part of the E2/000 series) with 55dB to 64dB.

Studs along the outer radius

Another option to reduce the rolling noise of an e-chain is the use of dampening studs. This small modification, which can be implemented in almost all chain types, reduces the noise level of an e-chain during placement down by a further 5dB.

Retrofit brake

Similar to the dampening studs in the outer radius of the chain just described, the igus designers have also found ways to reduce the noise level for other series. Rubber elements can be attached to the horizontal stops of the e-chains of the E4Q series, which dampen the stop-dog noise. The e-chains are therefore 17dB quieter than the 4040C series.

For more information and inspiration on noise reduction, click here.