New material iglidur® K250 in automotive applications

Julio Pauli | 9. April 2020

Due to our modern injection moulding production process, the desired iglidur® plain bearing can be manufactured in almost any geometry, for example as a flexible iglidur® clip bearing or flanged bushing especially for a quick assembly in sheet metal solutions.

These are used in interior hinges and seats. For this purpose, igus® constantly develops new, optimised materials within the scope of its iglidur® material product range. Wear results of our new material iglidur® K250, which is characterised by a high flexibility and low moisture absorption, are presented below. Compared to the igus classic iglidur® M250, the tribological properties could also be improved.

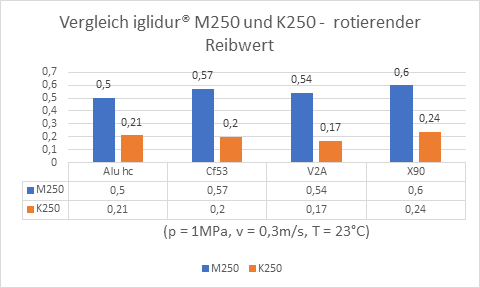

The coefficient of friction of K250 was more than halved for all tested counter partners.

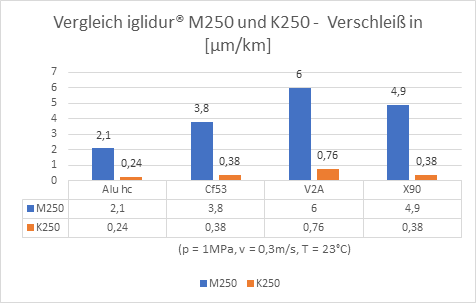

The wear rate in [μm/km] in rotation (see table for loads) is 10 times lower for K250 compared to M250.

The material retains its flexibility even in extreme cold and dry conditions and is therefore particularly suitable for flanged or double flanged bushes.

We will continue to conduct further tests on our new material iglidur® K250 in the future and shall keep you up to date.

We would be happy to show you further advantages of our polymer plain bearings.

Feel free to contact me:

Julio Pauli

Phone: +49(0)2203-9649-7042

e-mail: jpauli@igus.net

Free online consultation: igus Chat, Teams, Skype, WhatsApp, WeChat

Follow us on: linked.in, Instagram, Facebook

Enjoy browsing! Thank you for your time.

PS: plain bearings, spherical bearings, linear bearings, ball bearings, special sliders, gears, or individually customised designs – the iglidur® Designer leaves nothing to be desired. Request part now and receive a quotation by tonight.

More information: automotive industry, polymer plain bearings for automotive interior, exterior, and engine compartment applications