Low-cost plate handling laboratory

Ulf Hottung | 20. June 2020

Why use automation in the laboratory?

Many small laboratories want to optimise their processes and increase their throughput rates but recoil at the frequently high costs and time-consuming integration work, when only simple combinations of devices or magazines are required.

Until now, many routines such as “insertion/removal” have been performed manually, which ties up personnel and costs time and money.

What is important to the operators?

Among the 5 most frequent answers from laboratory operators about what makes a good laboratory instrument, these statements are very often found:

- Low investment costs

- Easy operation by the user

- High throughput thanks to 24/7 operation

- Small amount of floor space required

The “S-Lab Plate Handler” focuses on customer requirements

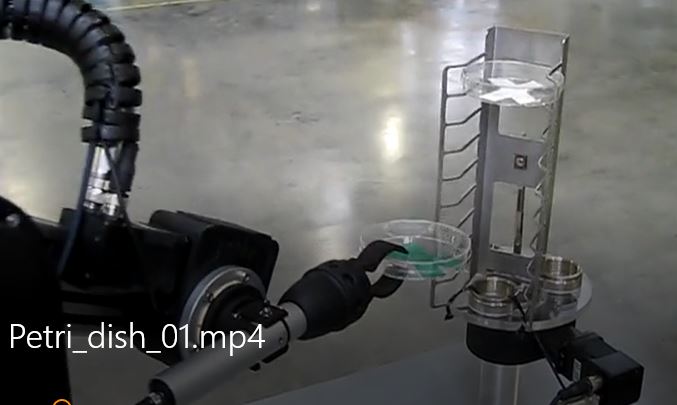

Our customer, Peak Analysis and Automation (UK and USA), took all this to heart when developing an S-Lab Automated Plate Handler and developed a device that enables the insertion and removal of Petri dishes and well plates/microwell plates with 300 (!) different devices.

How can igus meet these requirements?

The customer came to igus due to PEAK’s own requirements to provide a maintenance-free and lubrication-free, cost-effective and multi-functional device. In addition to the igus energy chain in the lift housing, the main functional elements also come from igus.

A special toothed belt axis based on the ZLW-0630 for the vertical movement, and a driven PRT slewing ring bearing with toothing for the rotation axis of the tower are used. Added to this is the above-mentioned E2 micro energy chain as cable guidance for the gripper.

Satisfaction convinces!

…. The customer is so satisfied with igus that he has agreed to write an article for the press, and on another Internet page, he has placed an interesting video in which our products can be seen in operation. Integral, simple, great!

Press report (English):

https://www.scientistlive.com/content/lab-automation-case-study

Is there any obvious solution, even without the comprehensive integration into the various control systems?

“Let’s give it a try. With domestic remedies.”

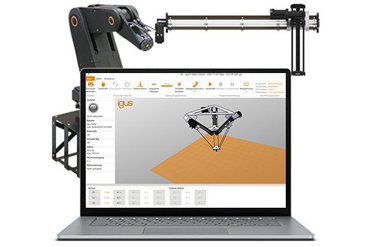

The success of our customer has spurred us on to try this ourselves. Of course, without the complex device connection and with one of our robots, very simplified but, somehow, cool! Here’s the video:

Even though the robot shown is not a cobot from the robolink modular kit and would therefore have to be housed.

The robolink control system software and controller interfaces nevertheless make simple integrations possible.

Our automation team is looking forward to your questions.