Is there a poor press fit due to anti-corrosion agent?

Lars Butenschön | 9. September 2021

Bearing damage can often be traced back to an insufficient press fit. In addition to inadequate lubrication or incorrect design, bearing bushings that are insufficiently located in the bearing position are among the most frequent causes of premature failures. There are many reasons for insufficient press fit. But did you know that anti-corrosion agents are part of it?

Why is the press fit so important?

In particular, bearings intended for dry operation are designed in such a way that the relative movement in the bearing position occurs exclusively between the bearing and the shaft, or the Bearing and bearing pin. Depending on the bearing design, it is not only the inner surfaces that offer good sliding properties – the shafts or Pins are also usually optimised for movement in the bearing. The situation is different for the inner surfaces of the housing holes.

Accordingly, it is disadvantageous if the press fit of the bearing is lost and the bearing moves in the housing hole.

Another problem can be the additional mechanical load on the bearing. If, as a result of the movement, parts of the bearings protrude from the housing, the load can no longer be absorbed by the entire component. The surface pressure in the bearing increases. Edge loads or shear forces can also damage the bearing.

The types of damage range from sheared-off bearing flanges to destroyed bearings on the shafts.

The most common causes of inadequate press fit include changes in the mechanical component stress, for example thermal changes or moisture conditions. These can be avoided by choosing the right material. Other causes may be incorrect or inappropriately chosen component tolerances.

Will the press fit reduce due to anti-corrosion agent?

To protect against corrosion in the bearing point, bearing manufacturers recommend the application of additional anti-corrosion agents on dry-operating bearings. These are often waxes that are applied once in the housing hole during assembly. This means the bearing point can be protected against corrosion even without permanent lubrication.

The catch? Anti-corrosion agents can worsen the press fit by reducing the static friction and therefore the force required to press out the bearing. In order to examine this effect in more detail, we carried out tests with various common anti-corrosion agents.

Conclusion: With the right anti-corrosion agent you can actually improve the press fit

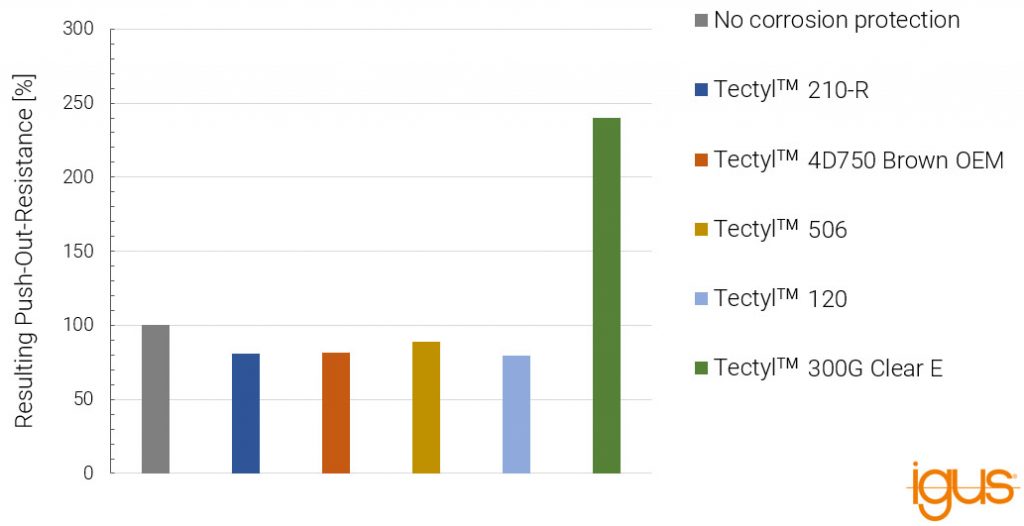

In order to investigate the effect of anti-corrosion agents on the press fit of bearings, we conducted press-out tests with iglidur® G bearings in combination with various anti-corrosion agents of the brand TectylTM. Bearings with an inner diameter of 40mm, an outer diameter of 44mm and a length of 40mm were first pressed into a test fixture pre-treated with various anti-corrosion agents and then pressed out while measuring the necessary force. The measured values were then compared with the reference values without anti-corrosion agent in a diagram.

The result shows that the press-out force applied is strongly influenced by the respective anti-corrosion agent. Whereas, for example, with the anti-corrosion agent Tectyl 210-R approx. 80% of the original press-out resistance remains, which could be increased to over 240% with the use of Tectyl 300G Clear E and therefore significantly improved. It is crucial to use the correct anti-corrosion agent for the respective application.

We provide expert advice free of charge!

Whether in the selection of the right anti-corrosion agent for our iglidur® plain bearings or the design of your bearing point. We will support you free of charge from the design stage to the delivery of the finished product.