Insert energy chain on the side

mkogelmann | 5. May 2020

The installation space for energy chains is often limited in height. One solution, although not always practical, is then to reduce the bend radius of the energy chain. But this is not always possible. Either the reduction of the bend radius is not sufficient for the chain to fit into the installation space, or it is simply not possible because the cables and hoses used do not allow a smaller bend radius.

Simply side-mounting the energy chain is often the best solution.

Support available

However, some points must still be observed. If the energy chain can be supported in both the fixed and the moving run, longer travels are also possible. The igus energy chains require no additional wear pads or similar. You can choose igus polymer, stainless steel (material: AISI 304) or galvanised steel as a good glide surface.

Install without support

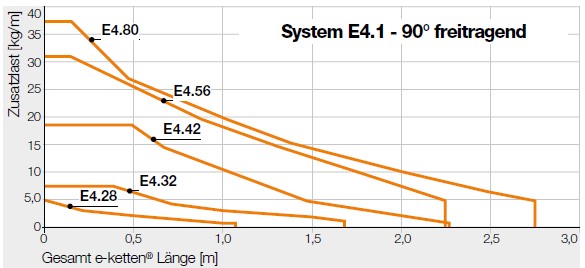

If, on the other hand, the chain is installed without support, or if supports are provided only on the moving end and/or fixed end, we speak of unsupported applications. The maximum unsupported length of the chain depends primarily on which e-chain series you have chosen and how much fill weight the chain must carry.

Generally speaking, the shorter the length of a chain link and the higher the fill weight, the shorter the unsupported length. Smaller radii and a larger inner width also positively favour the unsupported length. The e-chains with undercut design are particularly suitable for such applications, e.g. the E4.1 or E4.1L series

How should cables and hoses be laid and strain-relieved?

These two points are important and require special attention. Safe strain relief and clear separation of the cables and hoses are the basic prerequisites for a reliable operation.

Suitable strain relief elements here are igus CFX clamps, CFB strain relief plug-in system or tiewrap plates.

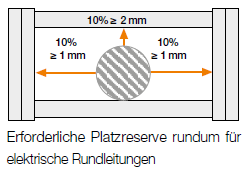

All cables and media guides must be neatly separated from each other. The space requirements must be observed as in other installation types.

For electrical cables, plan 10% of the cable diameter, but at least 1mm as free space on the left and right. For the electrical cable allow 10% or at least 2mm. For hydraulic hoses it is at least 20%.

In addition, however, when selecting the separators, it is important to ensure that they are not pushed down by the weight of the cables. The cables that lie underneath could get jammed. To avoid this, snap-in separators or spacers are used.

Our recommendation

Because of the large number of possible applications, we recommend that you consult us for individual cases or, even better, have free project planning prepared by us.